Understanding the Standing Seam Roof Machine A Key Tool in Modern Roofing Techniques

In the realm of roofing technology, one machinery that stands out for its efficiency and durability is the Standing Seam Roof Machine. This innovative tool has revolutionized the way metal roofs are manufactured and installed, offering a superior alternative to traditional roofing methods.

A standing seam roof machine, as the name suggests, is specifically designed to create the signature interlocking seams found on standing seam metal roofs. These roofs, characterized by their raised, vertical seams that run vertically from the roof's eaves to its ridge, are known for their aesthetic appeal, weather resistance, and longevity. The machine plays a pivotal role in this process, transforming flat metal sheets into the distinctive, secure panels.

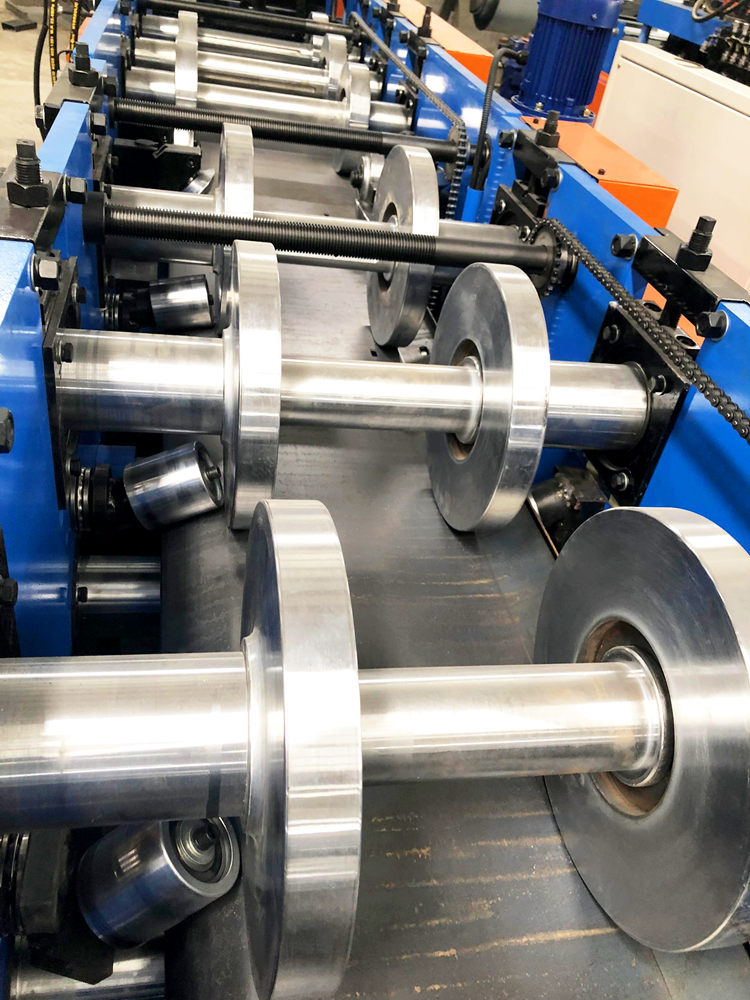

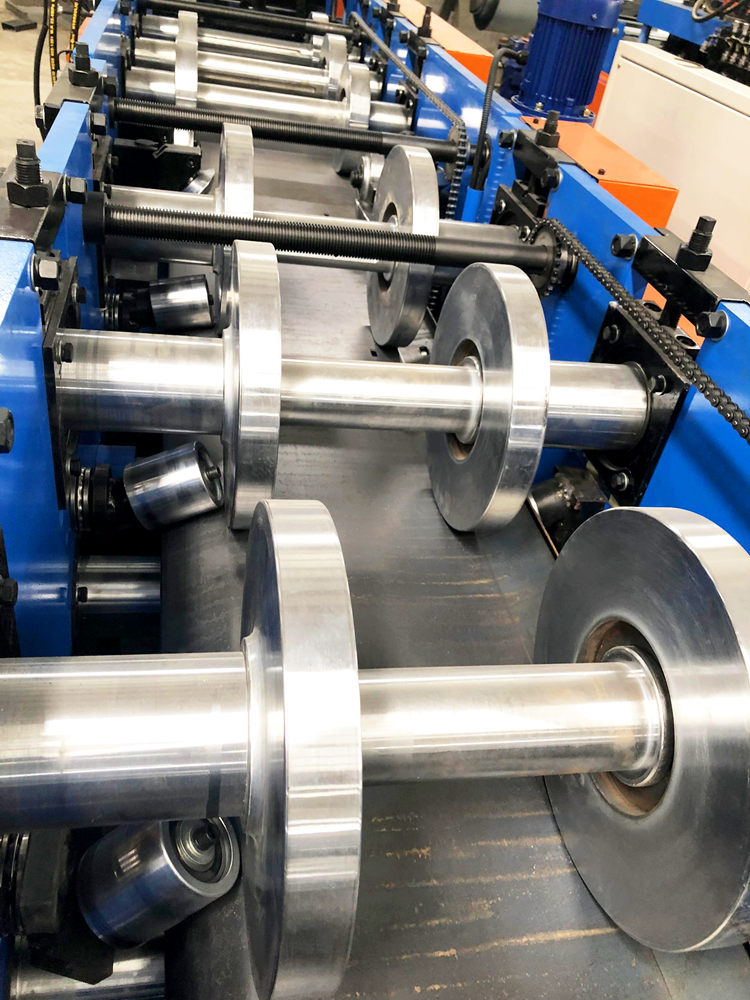

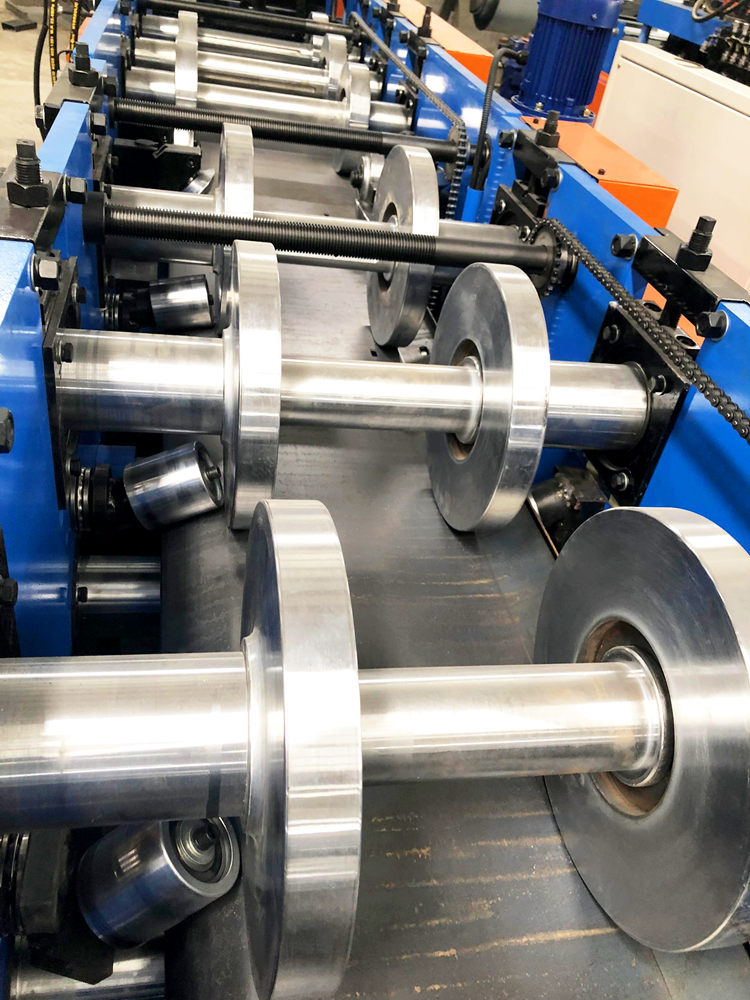

The operation of a standing seam roof machine is a testament to modern engineering. It typically consists of a roll former, which rolls and shapes the metal sheet, and a seamer, which crimps the edges together to form the standing seam. The process begins with a flat metal coil being fed through the roll former where it is gradually shaped into the desired profile. As it progresses, the seamer locks the edges together, creating an airtight, water-resistant seal.

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

standing seam roof machine

standing seam roof machine. Its ability to produce consistent, high-quality seams ensures a robust and reliable roof that can withstand harsh weather conditions. Moreover, these machines can work with a variety of metals, including aluminum, steel, and copper, providing versatility in material selection.

Beyond practicality, the standing seam roof machine also contributes to sustainability efforts. Metal roofs are recyclable, and their energy efficiency can lead to reduced energy consumption, making them an eco-friendly choice. Furthermore, the durability of standing seam roofs often negates the need for frequent replacements, reducing waste and environmental impact.

In conclusion, the standing seam roof machine is more than just a piece of equipment; it is a symbol of progress in the roofing industry. Its capability to manufacture strong, visually appealing, and sustainable roofs has made it an indispensable tool for contractors and builders alike. As technology continues to evolve, we can expect even more advanced standing seam roof machines to emerge, further enhancing the efficiency and aesthetics of metal roofing systems.

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs

The standing seam roof machine's precision and speed significantly reduce installation time and labor costs