Square pipe roll forming machines have revolutionized the manufacturing landscape by enhancing the precision, efficiency, and customization of metalworking processes. These machines, designed to shape metal sheets into square tubing, cater to industries like construction, automotive, and infrastructure development. The following narrative unfolds an in-depth look at the experience, expertise, authoritativeness, and trustworthiness surrounding square pipe roll forming machines.

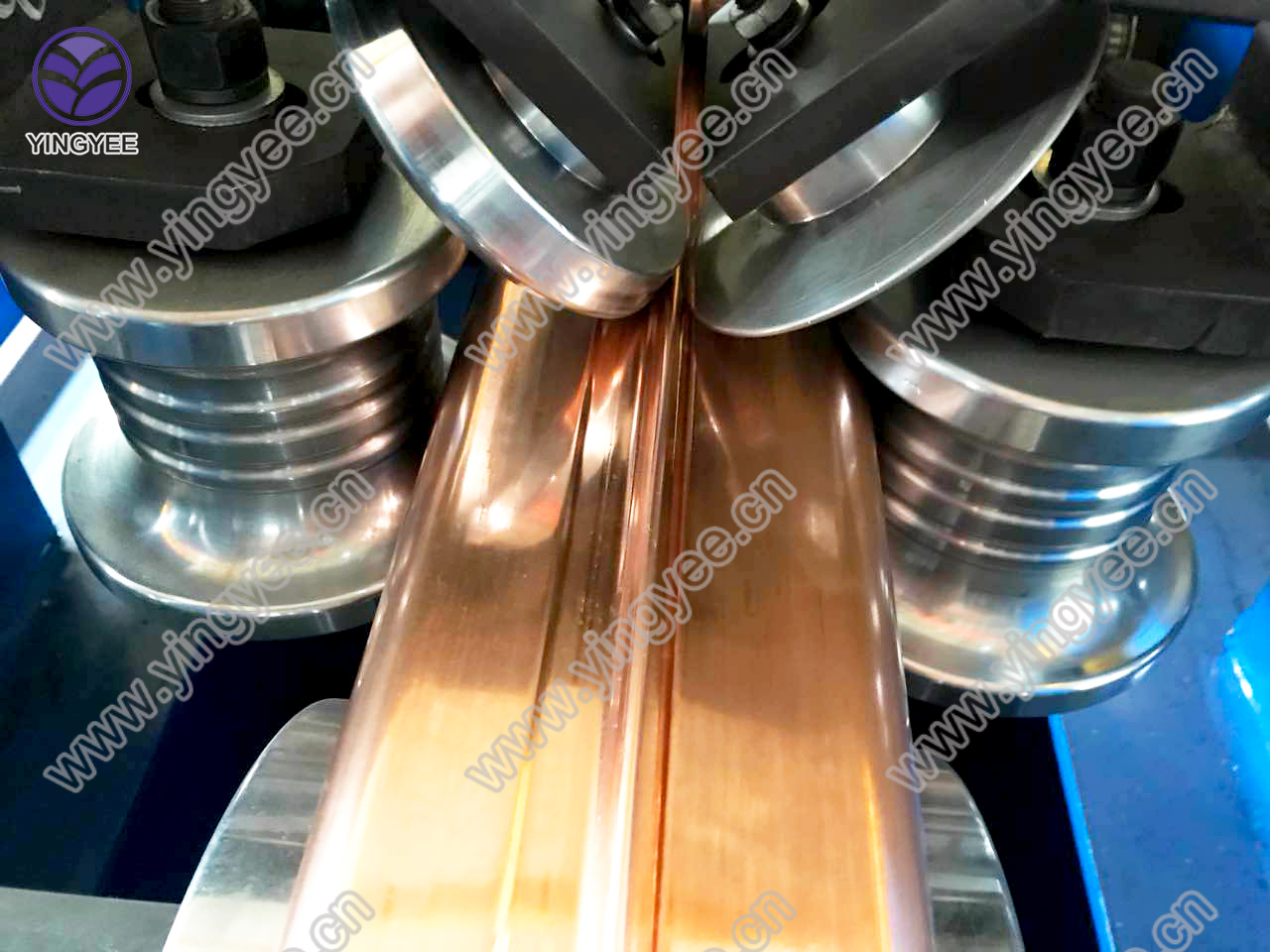

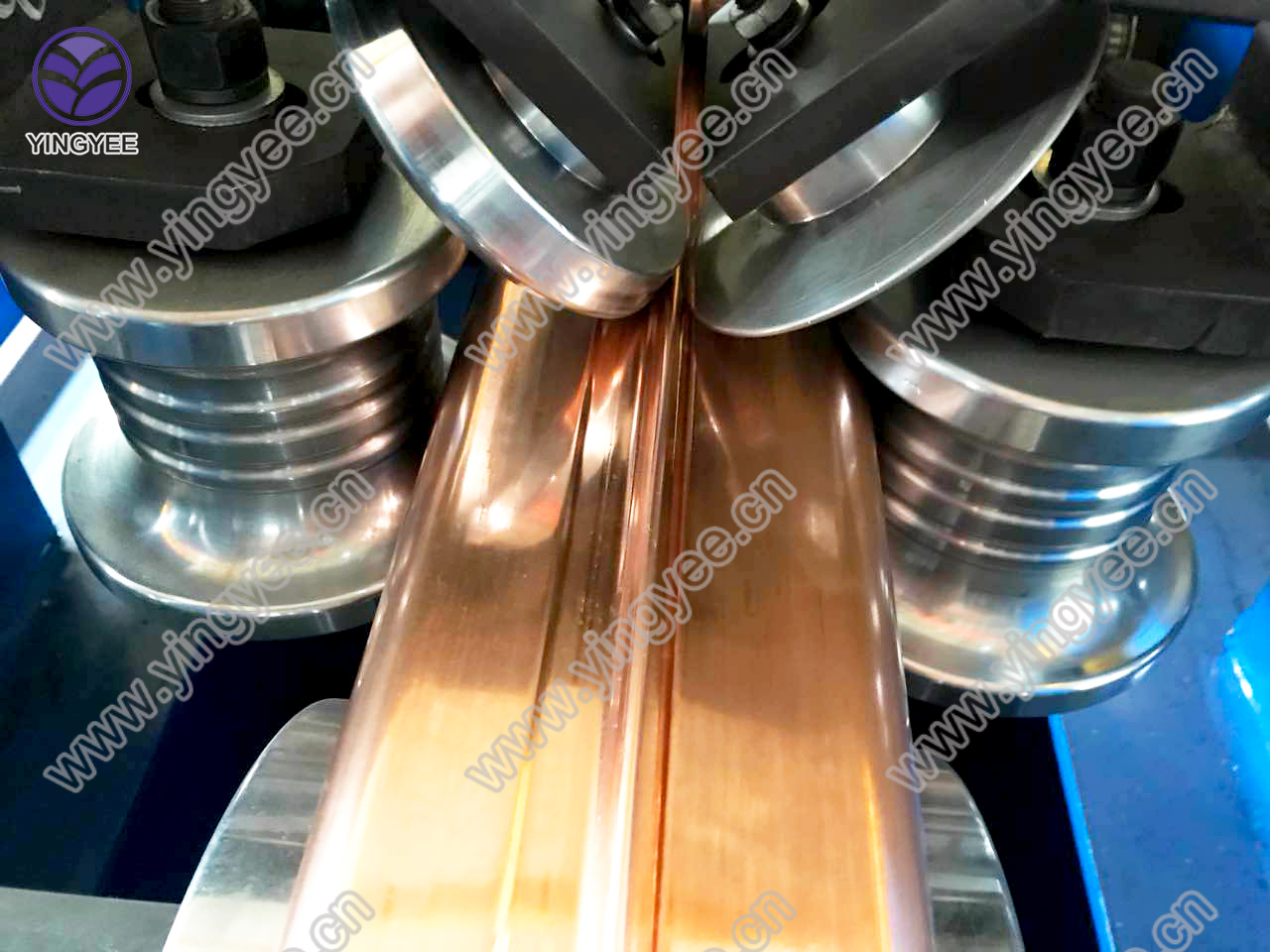

The journey of mastering a square pipe roll forming machine starts with understanding its core components and functionality. At its essence, this machine integrates a decoiler, leveling unit, punching system, roll forming unit, and cutting equipment, each segment fine-tuned for seamless operation. The decoiler holds the raw metal coil, feeding it into the leveling unit where precision is paramount. This step ensures a flawless feed, setting the stage for the subsequent roll forming process. Operators, often experts with years in metal fabrication, value the consistent quality output these machines deliver, saving time and reducing waste in comparison to traditional methods.

In terms of expertise, it’s crucial to acknowledge the advanced technological features that these machines boast. The roll forming unit's design has evolved to incorporate Computer Numerical Control (CNC) technology, allowing for unprecedented accuracy and repeatability. This automated precision is not just a testament to the machine's capability but also reflects the operator's skill in programming and fine-tuning operations. Skilled technicians are trained to harness these technological advancements, ensuring each square pipe meets exacting specifications with minimal deviation. This expertise is further exemplified by continuous improvements and upgrades in tooling, another pivotal aspect of roll forming that ensures the machine's adaptability to various metal types and thicknesses.

Authoritativeness comes into play when considering the industry's reliance on these machines.

Square pipe roll forming machines are regarded as indispensable assets within sectors that require consistent reliability and output. Their capacity to work long hours without diminishing product quality proves pivotal in sectors such as construction, where demand for structural support elements is high. Manufacturers who produce these machines are often industry leaders, contributing to advancements in metallurgy and manufacturing techniques. Their authority is further cemented through rigorous testing and standards compliance, assuring users that each product meets international safety and performance benchmarks.

square pipe roll forming machine

Trustworthiness emerges from the enduring relationship between manufacturers and operators who invest in square pipe roll forming technology. Leading brands in this domain offer comprehensive support services including training, maintenance, and after-sales assistance, fostering a trust-based relationship. These services are crucial in ensuring that the machines operate at peak efficiency and that any potential technical issues are swiftly addressed. Crafting square pipes with consistency demands not just superior machinery but also a reliable partnership with the manufacturer, which translates into sustained operational success.

In a landscape driven by customization and rapid production needs, the square pipe roll forming machine stands out as a beacon of manufacturing prowess. The ongoing innovations in this field mirror a commitment to enhancing productivity while maintaining high standards of quality and precision. Such evolution ensures that practitioners, whether they are operators, manufacturers, or industry experts, can rely on square pipe roll forming machines for their pivotal role in modern metalworking applications.

These aspects reveal that square pipe roll forming machines are not merely tools but are pivotal components that define the future of efficient manufacturing. As industry trends evolve, leaning into more sustainable and automated practices, the role of these machines will undoubtedly expand, integrating even more sophisticated technologies and materials. This foresight mirrors a broader shift towards enhanced manufacturing solutions, marking the square pipe roll forming machine as a cornerstone of industrial excellence.