The servo control feeding storage racking forming machine stands as a remarkable innovation in the field of industrial automation, providing an unparalleled solution for businesses aiming to optimize storage systems with precision and efficiency. This advanced machinery embodies a combination of automation technology, mechanical engineering, and intelligent design, catering to the modern industry's need for speed, accuracy, and reliability.

Drawing from firsthand experience, operators have witnessed significant improvements in productivity with the implementation of servo control technology. The precision offered by servo motors in controlling position, velocity, and torque ensures that the complex processes of shaping and forming storage racks are conducted with minimal error margins. This level of accuracy is transformative for industries relying on substantial inventories, such as logistics, manufacturing, and warehousing.

Expertise in the domain of automation is apparent in the machine’s design.

It integrates state-of-the-art servo control systems that interact seamlessly with sophisticated software platforms. These systems allow for real-time monitoring and adjustments, facilitating a dynamic response to any deviations in the production process. Engineers and operators who have utilized these machines in their production lines often remark on the ease of use brought forth by intuitive interfaces and automated adjustments, significantly reducing downtime and maintaining a smooth operational flow.

The authoritativeness of the servo control feeding storage racking forming machine is underscored by its presence in leading industry workshops and seminars where automation experts convene to discuss advancements in machinery and process optimization. Professionals in the field recognize this machine as a cornerstone of modern storage solutions, often endorsed in technical papers and case studies that highlight its superior performance compared to traditional forming machines. The growing body of evidence supporting its advantages speaks volumes about its capability and the trust that industries place in its functionality.

Trustworthiness is another critical aspect, enhanced by the machine’s robust safety features and compliance with international manufacturing standards. The construction of the machine prioritizes operator safety without compromising on speed or precision, making it a reliable choice for businesses. Additionally, comprehensive support and training provided by manufacturers ensure that users are well-equipped to leverage the machine's full potential, fostering a sense of confidence among new adopters and seasoned operators alike.

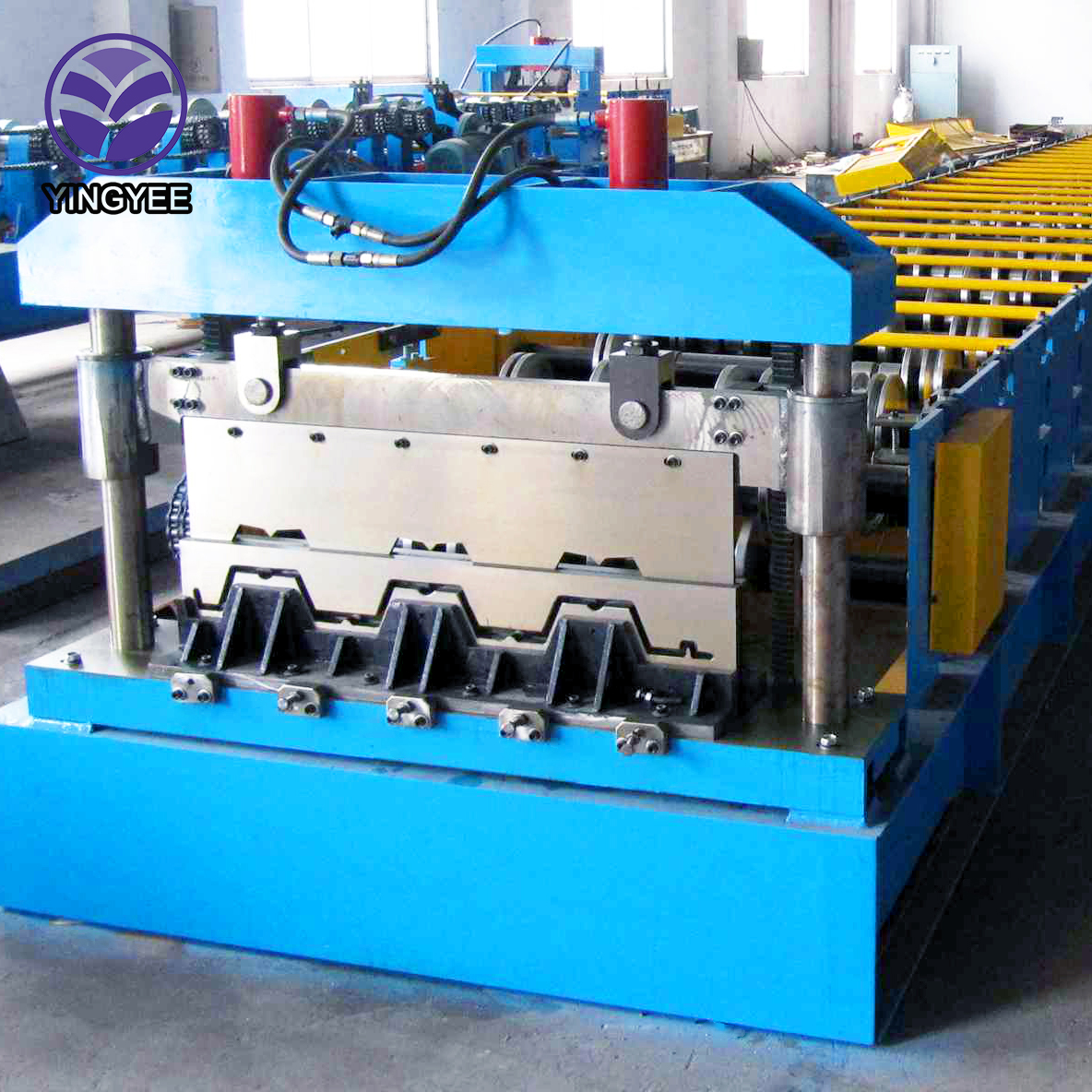

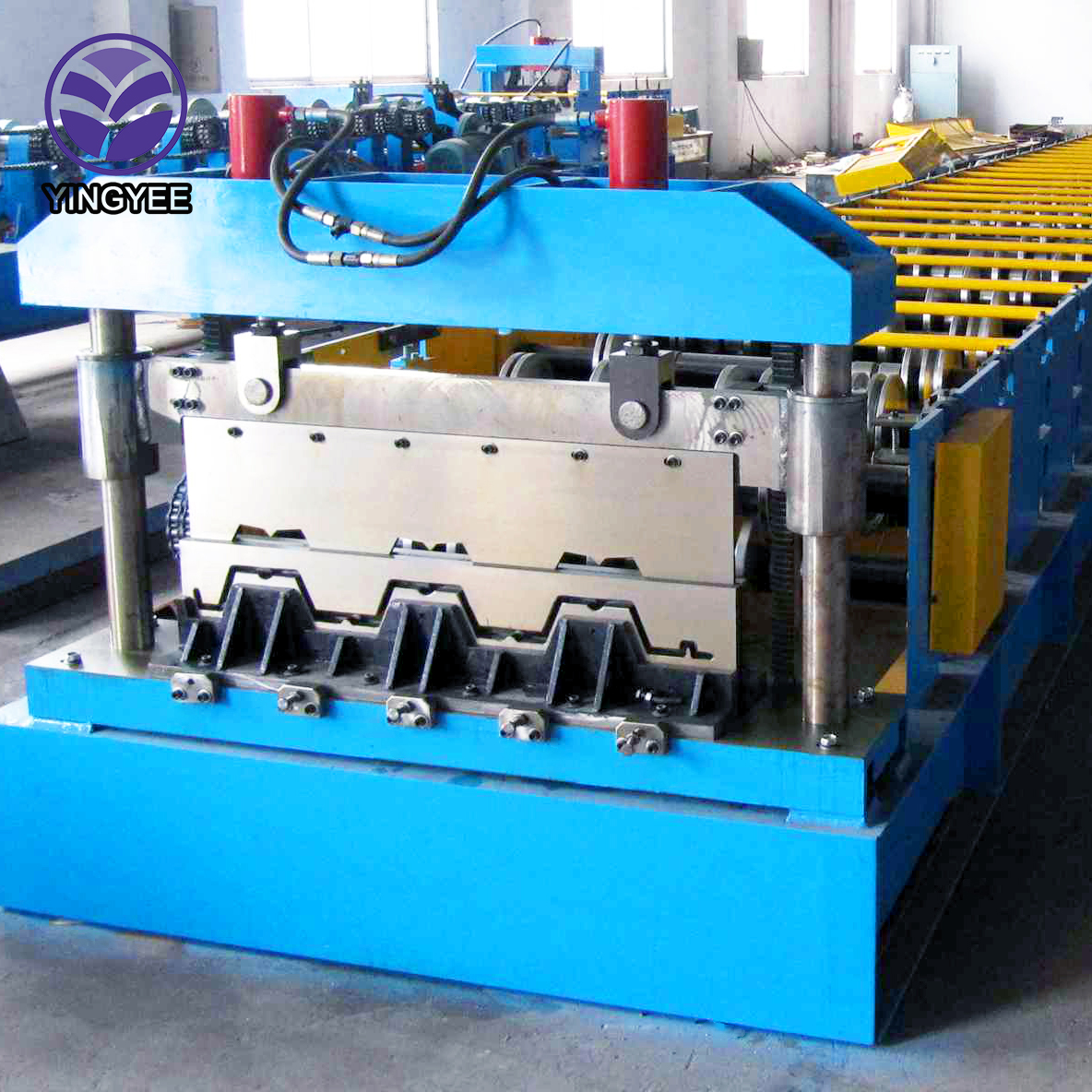

servo control feeding storage racking forming machine

Beyond technical specifications, the practical benefits of the servo control feeding storage racking forming machine are compelling. Reduced material waste, heightened production speeds, and an increase in overall productivity are achieved without the hefty costs traditionally associated with high-precision machinery. This cost-effectiveness, coupled with the reduced need for manual intervention, translates to a higher return on investment and encourages smaller businesses to adopt advanced automation technologies.

Real-world applications highlight the machine's versatility across different sectors, from automotive to consumer goods industries, adapting to various rack designs and specifications effortlessly. Its ability to cater to bespoke storage solutions positions it as a flexible tool for businesses looking to tailor their systems to specific logistical demands.

Critically, the integration of data analytics tools with the servo control machines offers a futuristic approach to quality control and process optimization. By collecting and analyzing real-time data, businesses can implement predictive maintenance strategies, minimize machine downtime, and ensure that quality benchmarks are consistently met or exceeded. This data-driven approach not only helps in maintaining high standards of production but also informs strategic decisions surrounding operational efficiency and innovation.

In conclusion, the servo control feeding storage racking forming machine represents a convergence of technology, expertise, and industry needs. It embodies the future of automated forming solutions, marrying precision with efficiency while maintaining a steadfast commitment to safety and reliability. For those seeking to stay ahead in a competitive market, investment in this technology is not merely an option but a strategic imperative.