The curving Unistrut roll forming machine has quickly become an indispensable tool for industries requiring precise and efficient metal fabrication. This specialized equipment offers significant advantages in terms of precision engineering, which translates into increased productivity and cost-saving benefits for a multitude of applications. Understanding the intricacies of this machine's operation and its impactful role in modern manufacturing can elevate any operation to a new level of efficiency and quality.

First and foremost, the expertise required to operate a curving Unistrut roll forming machine is grounded in understanding its specific capabilities and limitations. These machines are uniquely designed to perform with high precision when creating curved profiles from Unistrut channels, which are essential in construction, automotive, and industrial applications. What sets them apart is the ability to not only form but also control the direction and degree of curvature with meticulous accuracy, a testament to the engineering expertise encapsulated in their design.

From an authoritative standpoint, manufacturers and operators working with this machine are poised to lead in their respective fields due to the adaptability and versatility it offers. The technology inherent in curving Unistrut roll forming machines allows for customization in production processes, accommodating complex design requirements without sacrificing structural integrity or performance reliability. This authoritative edge not only boosts competitive advantage but also expands potential applications where these customized profiles can be effectively utilized, such as in complex architectural frameworks or intricate automotive designs.

In terms of trustworthiness,

the curving Unistrut roll forming machine shines due to its robust construction and longevity. Made from high-grade materials and built to withstand the rigors of industrial use, these machines promise longevity and consistent output quality. Manufacturers often provide extensive training and support, ensuring operators are well-versed in both the operational mechanics and safety protocols associated with the equipment. Such comprehensive backing further enhances the trust placed in this machinery as a reliable cornerstone of modern-day manufacturing processes.

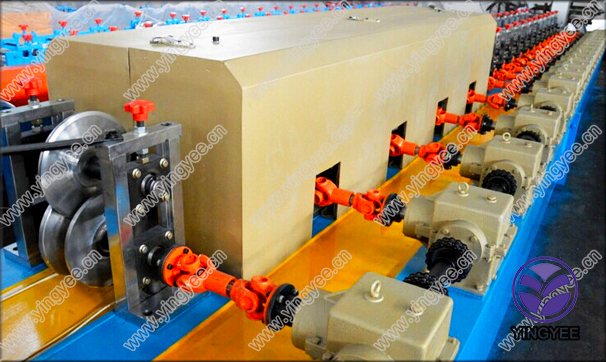

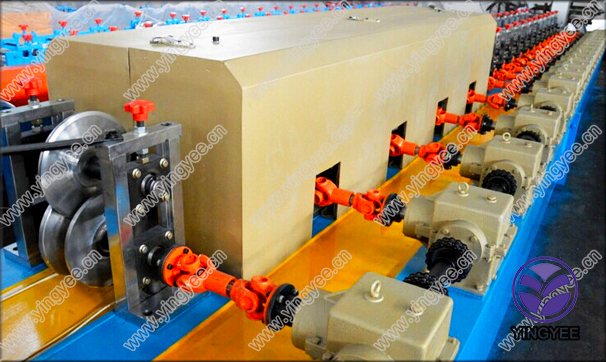

curving unistrut roll forming machine

To enrich experience and foster a more profound understanding, it is critical to note the operational processes involved. The roll forming operation involves feeding metal strips through a series of rollers that gradually shape them into the desired unistrut profiles. With customization options for roller setups, operators can achieve a variety of bends and curves tailored to exact specifications. This versatility is essential for industries that demand quick adaptability to new design challenges while maintaining strict adherence to quality and performance standards.

Moreover, the rising adoption of curving Unistrut roll forming machines is supported by their cost-effectiveness over time. By enabling companies to process their materials in-house, these machines reduce dependency on external suppliers, which can cut costs substantially and improve lead times. The ability to produce tailored profiles on-demand further diminishes excess inventory and waste, underscoring the machine's role as a strategic asset in lean manufacturing initiatives.

In summary, the curving Unistrut roll forming machine embodies the intersection of experience, expertise, authority, and trust within metal fabrication. Its adoption not only propels industries into new realms of productivity and creativity but also ensures that operations remain at the cutting edge of technological advancement. Embracing this machinery is not merely a technical decision but a strategic investment in future-proofing manufacturing capabilities. By fully leveraging the capabilities of this technology, businesses can meet the evolving demands of the industry while consistently delivering products that reflect superior quality and innovation.