Servo control feeding storage racking forming machine is a cutting-edge technology used in the manufacturing industry. This machine integrates servo control, feeding, storage racking, and forming capabilities to streamline and automate the production process.

The servo control feature of this machine allows for precise control and adjustment of various parameters such as speed, position, and force. This ensures consistent and accurate results in the manufacturing process, leading to high-quality products.

The feeding mechanism of the machine facilitates the smooth and continuous supply of raw materials to the production line. This reduces downtime and increases efficiency by eliminating the need for manual intervention in the feeding process.

The storage racking system of the machine provides a convenient and organized storage solution for raw materials and finished products. This helps in efficient use of space and easy retrieval of materials, contributing to a more organized and productive work environment

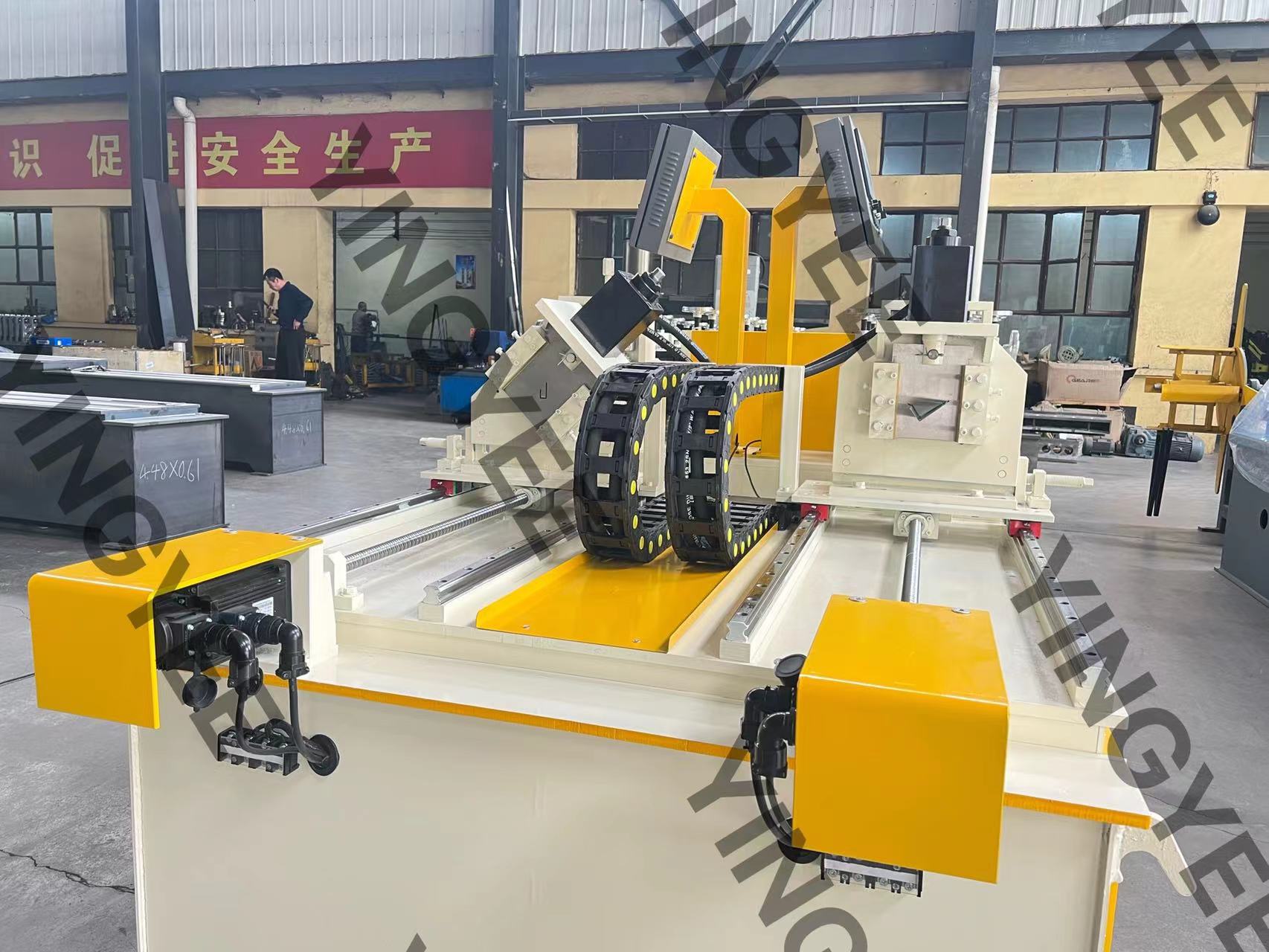

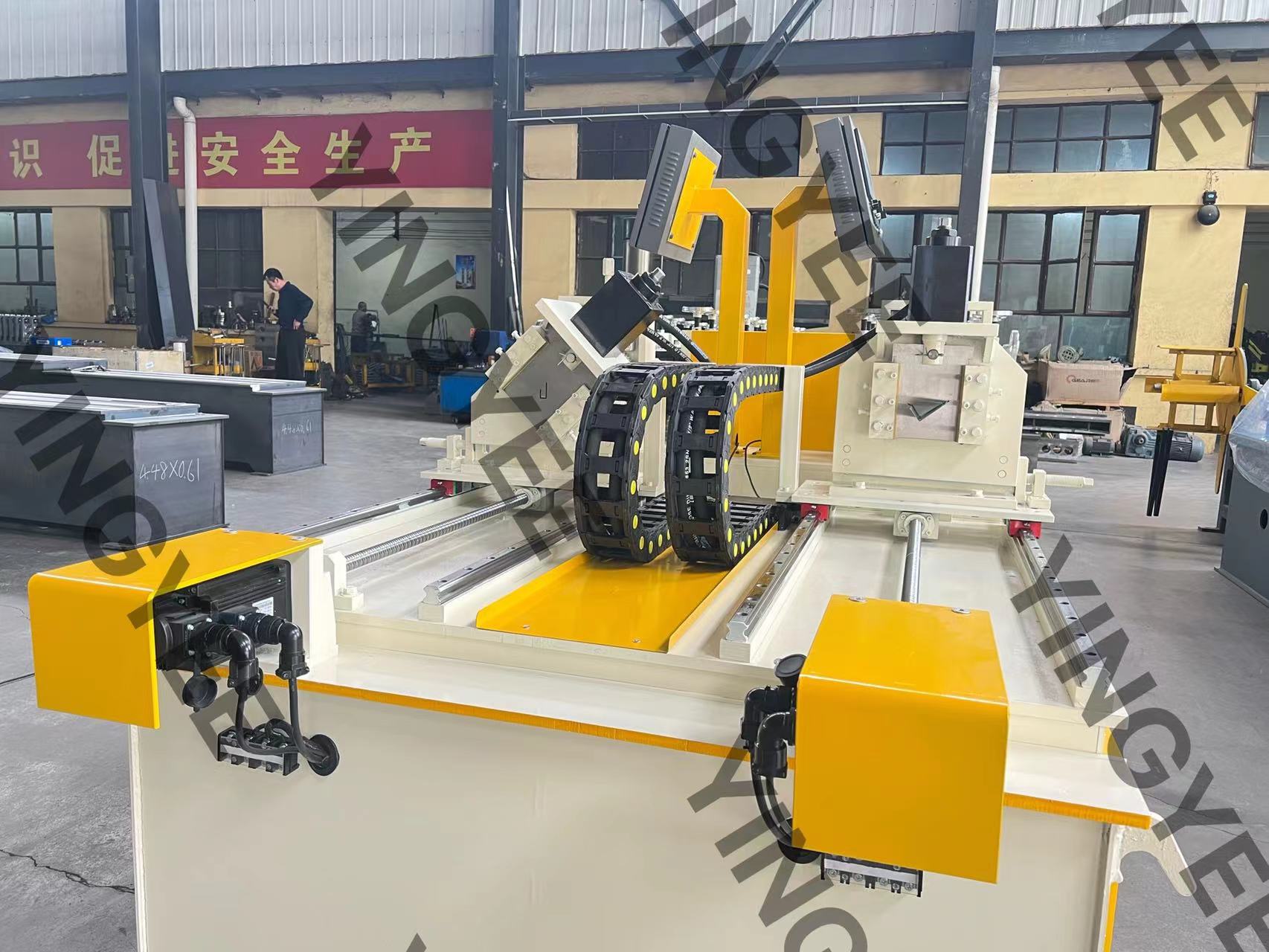

servo control feeding storage racking forming machine

servo control feeding storage racking forming machine.

The forming capability of the machine allows for the shaping and molding of materials into desired shapes and sizes. This versatile feature enables the production of a wide range of products with varying specifications, meeting the diverse needs of customers.

Overall, the servo control feeding storage racking forming machine offers a comprehensive solution for manufacturers looking to enhance their production process. By integrating advanced technology and automation, this machine helps in improving efficiency, increasing productivity, and ensuring the high quality of products.

In conclusion, the servo control feeding storage racking forming machine is a valuable asset for manufacturers seeking to stay competitive in the market. With its advanced features and capabilities, this machine provides a cost-effective and efficient solution for streamlining the production process and meeting the demands of the industry.