Understanding Purlin Metal Stud and Track Machines A Comprehensive Overview

In the realm of modern construction and manufacturing, the efficiency and precision of building materials play a pivotal role. One of the key innovations that have transformed the industry is the purlin metal stud and track machine. This machinery is engineered to streamline the production of metal studs and tracks, which are essential components in the construction of walls, ceilings, and various structural frameworks. In this article, we will explore the functionality, advantages, and applications of purlin metal stud and track machines.

What is a Purlin Metal Stud and Track Machine?

A purlin metal stud and track machine is a specialized piece of equipment designed to manufacture metal framing components. It typically works with cold-formed steel, which is a popular choice due to its strength, lightweight nature, and resistance to environmental factors. The machine automates the entire process of shaping, cutting, and finishing metal into various profiles, which include studs, tracks, and purlins.

Key Functions of the Machine

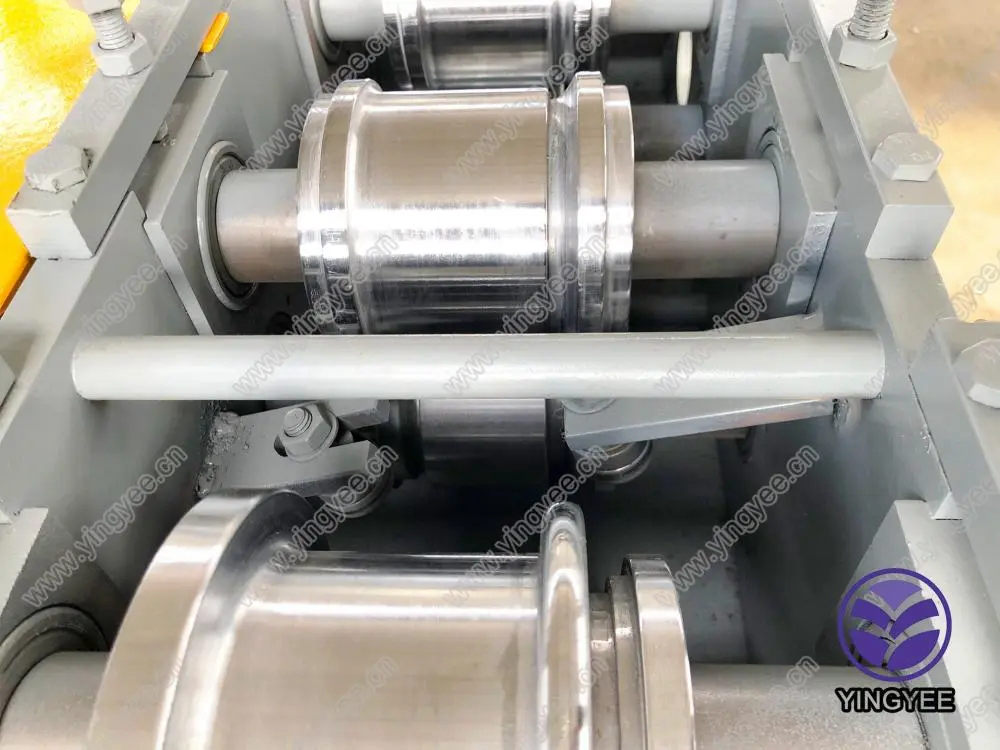

The primary function of a purlin metal stud and track machine is to produce metal studs and tracks with precision. The process begins with coils of cold-rolled steel, which are fed into the machine. The machine then performs several operations, including

1. Uncoiling The steel coil is unwound and prepared for shaping. 2. Forming Using advanced roll-forming technology, the machine molds the steel into specific profiles. 3. Cutting The formed metal is cut to the desired lengths, ensuring consistency in product size. 4. Punching and Notching Holes or notches can be added to facilitate easy assembly and reduce weight. 5. Finishing The final products can undergo additional treatments, such as galvanizing, to enhance durability.

Advantages of Using Purlin Metal Stud and Track Machines

1. Efficiency These machines significantly increase production speed compared to manual methods. This efficiency allows manufacturers to meet tight deadlines and reduce labor costs.

2. Precision and Consistency Automated processes reduce human error, resulting in accurate dimensions and uniformity across products. This consistency is crucial in construction to ensure structural integrity.

3. Versatility The machines can produce a variety of profiles, making them suitable for different applications, including commercial, residential, and industrial construction.

5. Reduced Labor Requirements Automation means that fewer workers are required to operate the machinery, leading to lower labor costs and the ability to allocate personnel to other essential tasks.

Applications of Purlin Metal Stud and Track Machines

Purlin metal stud and track machines are utilized in various sectors within the construction industry

- Commercial Buildings Metal studs and tracks are widely used for constructing interior walls and ceilings in office buildings, shopping malls, and hotels.

- Residential Housing With the rising popularity of steel framing in homes, these machines provide an efficient means of creating durable and lightweight wall systems.

- Industrial Applications Factories and warehouses often require strong and sturdy frameworks, which can be efficiently produced using these machines.

- Modular Construction As modular building techniques gain traction, the ability to produce customized metal studs and tracks quickly and efficiently becomes invaluable.

Conclusion

In conclusion, the purlin metal stud and track machine represents a significant advancement in the construction manufacturing industry. By enhancing efficiency, precision, and versatility, these machines contribute to the overall quality and durability of building projects. As the demand for metal framing continues to grow, investing in advanced machinery like the purlin metal stud and track machine will be indispensable for manufacturers seeking to remain competitive in a rapidly evolving market. Whether for commercial, residential, or industrial applications, the benefits of using these machines are clear, paving the way for innovation in construction and manufacturing practices.