Understanding the Metal Sound Barrier Cold Bending Machine

In the world of metal fabrication, efficiency and precision are paramount, especially when it comes to manufacturing sound barriers. The Metal Sound Barrier Cold Bending Machine stands out as a critical piece of equipment in this field, revolutionizing the way we approach sound insulation solutions in urban and industrial environments.

What is a Metal Sound Barrier?

Metal sound barriers are structures designed to reduce noise pollution from highways, railways, and industrial areas. They serve as an effective shield against noise, creating a more tranquil environment for communities adjacent to high-noise facilities. The effectiveness of a sound barrier greatly relies on its material, design, and installation technique. Metal barriers, particularly those made of steel or aluminum, are favored for their strength, durability, and ability to withstand the rigors of outdoor exposure.

The Role of Cold Bending Technology

The process of creating these sound barriers involves various manufacturing techniques, with cold bending being one of the most advanced methods. Cold bending refers to the process of shaping metal at room temperature. This technique provides several advantages compared to traditional hot bending methods, including reduced energy consumption, minimized risk of material degradation, and enhanced dimensional accuracy.

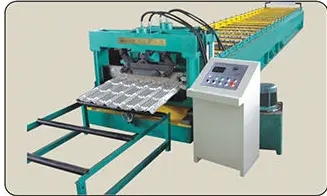

A Metal Sound Barrier Cold Bending Machine specifically employs this technique to produce panels and support structures more efficiently. By using hydraulic systems and advanced CNC technology, these machines can bend metal sheets into precise angles and shapes without compromising the integrity of the material.

Key Features of the Cold Bending Machine

1. Precision Engineering One of the standout features of the cold bending machine is its ability to achieve high levels of precision. The computerized controls allow for meticulous adjustments, enabling manufacturers to create customized designs that meet specific acoustic requirements.

2. Versatility These machines are designed to handle various types and thicknesses of metal sheets, making them suitable for diverse applications beyond sound barriers. This versatility ensures that manufacturers can adapt to different projects without needing to procure additional equipment.

3. Reduced Material Waste Cold bending is known for its efficiency when it comes to material usage. Since the process does not involve heating, there is minimal waste from trimming or reworking materials. This not only saves costs but also contributes to more sustainable manufacturing practices.

4. Enhanced Safety Features Modern cold bending machines come equipped with advanced safety mechanisms. These features help protect operators from potential hazards, ensuring a safe working environment. Automated systems eliminate the need for manual intervention during critical processes, thereby reducing the risk of accidents.

The Impact on Sound Barrier Construction

The implementation of Metal Sound Barrier Cold Bending Machines has significantly impacted the construction of sound barriers. The ability to produce complex shapes and designs quickly has enabled manufacturers to respond more effectively to the growing demand for improved noise control in urban areas.

Furthermore, the durability and effectiveness of metal sound barriers have been enhanced through cold bending techniques. By ensuring precise angles and tight joints, these barriers can better absorb and deflect sound waves, providing superior noise reduction compared to traditional methods.

Conclusion

In summary, the Metal Sound Barrier Cold Bending Machine represents a significant advancement in the field of noise control engineering. Its ability to deliver precision, versatility, and efficiency makes it a valuable asset for manufacturers striving to create effective sound barriers. As urbanization continues to grow and the need for noise mitigation intensifies, the role of such advanced machinery will only become more critical. Investing in these innovative machines not only enhances manufacturing processes but also contributes to a quieter and more harmonious living environment for communities worldwide.