EPS sandwich panel production line is an essential equipment used in the construction industry for manufacturing insulated panels. These panels are widely used for various applications such as building walls, roofs, and floors due to their excellent thermal insulation properties. The production line consists of several components that work together to produce high-quality EPS sandwich panels efficiently.

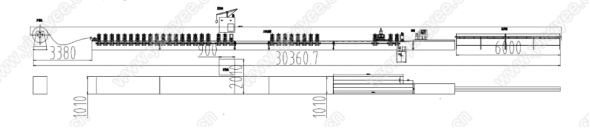

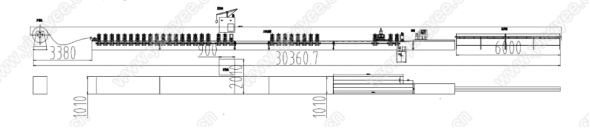

The first component of the production line is the uncoiling machine, which is used to unroll the coil of steel or aluminum sheets that will be used as the outer layers of the sandwich panel. These sheets are fed into the profiling machine, where they are shaped and cut to the desired dimensions. The profiling machine is equipped with cutting tools that ensure precise and accurate cutting of the sheets.

After the outer layers are formed, the next step is to prepare the core material, which is typically expanded polystyrene (EPS). The EPS beads are placed in a mold, and steam is injected to expand the beads and bond them together, forming a solid EPS panel. The EPS panel is then cut to the required size and shape before being sandwiched between the outer layers.

The next component of the production line is the laminating machine, which is used to bond the outer layers with the EPS core.

The laminating machine applies a special adhesive to the surfaces of the outer layers and the EPS core, ensuring a strong bond between the layers eps sandwich panel production line

eps sandwich panel production line. The sandwich panel is then passed through a pressing machine, which compresses the layers together to ensure a uniform thickness and a smooth surface.

Once the sandwich panel is pressed and cooled, it is ready for further processing. The panels can be cut to the required dimensions using a cutting machine and then stacked and packed for shipping. The entire production process is automated, with computer controls ensuring precision and consistency in the manufacturing process.

The EPS sandwich panel production line offers several advantages over traditional construction methods. The panels are lightweight, making them easy to handle and install, reducing labor costs and construction time. The panels also offer excellent thermal insulation properties, helping to reduce energy costs and maintain indoor comfort in buildings.

In conclusion, the EPS sandwich panel production line is an essential piece of equipment for manufacturing high-quality insulated panels for the construction industry. With its automated process and precise controls, the production line ensures the efficient and consistent manufacturing of EPS sandwich panels. These panels offer numerous benefits for construction projects, including lightweight construction, excellent thermal insulation, and cost savings.