When it comes to effective cable management solutions for outdoor use, the innovation brought about by the outdoor cable tray roll forming machine stands unparalleled. This sophisticated machinery combines advanced technology with practical engineering, resulting in an efficient production process for outdoor cable trays, which are essential for various industries including telecommunications, utilities, and construction.

The outdoor cable tray roll forming machine is a groundbreaking piece of equipment, designed to meet the increasing demands for high-quality, durable, and adaptable cable trays. This machine precisely shapes metal into trays that can withstand harsh environmental conditions, ensuring longevity and reliability in their application.

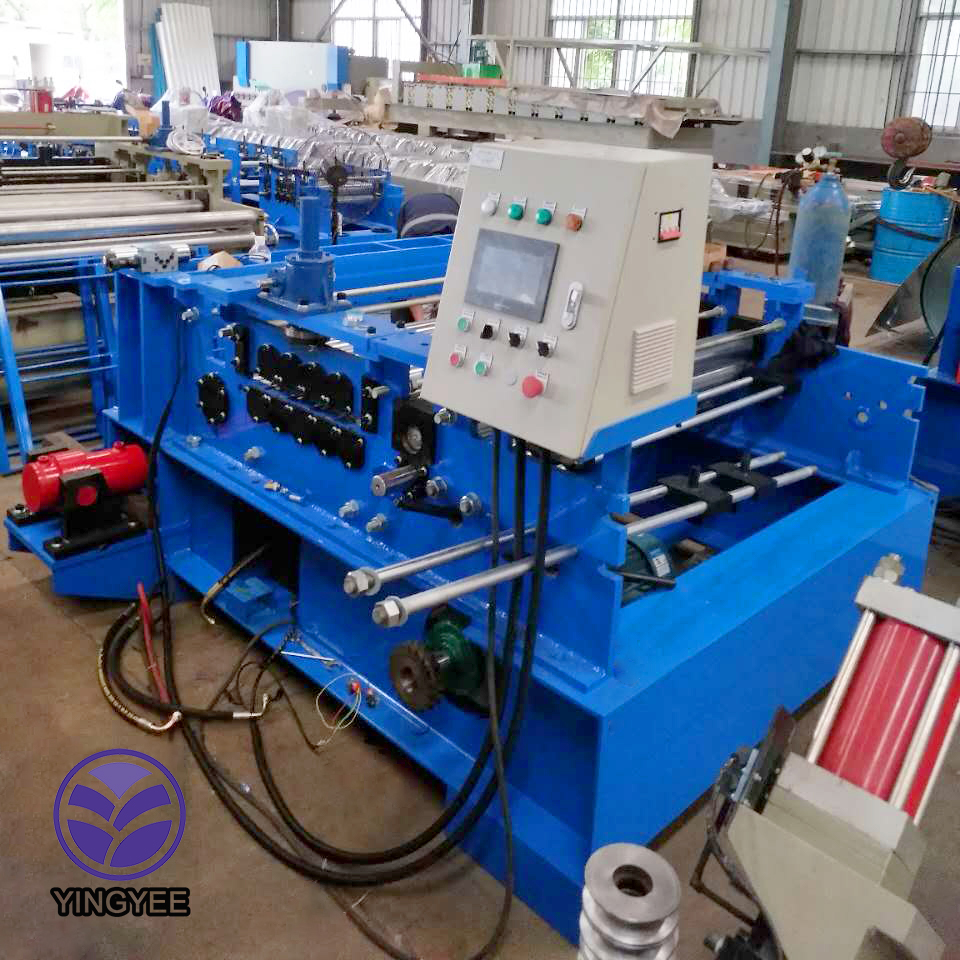

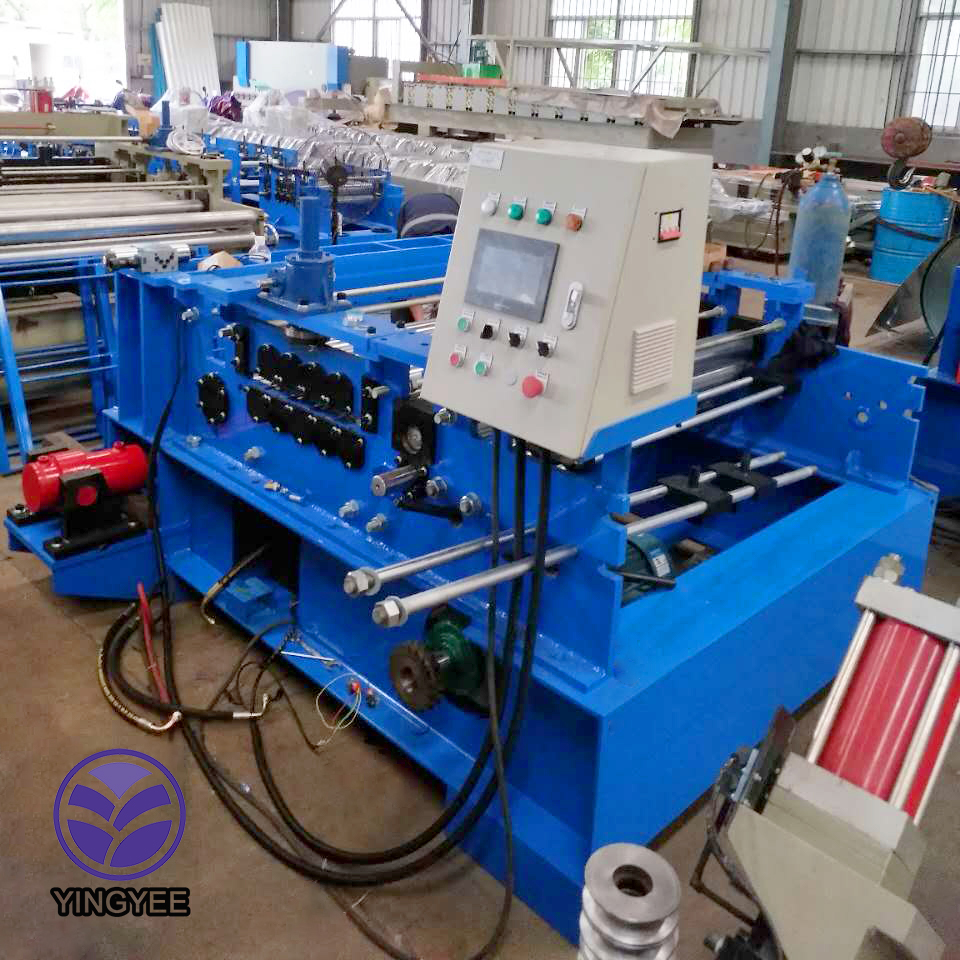

From an experiential standpoint, users of the outdoor cable tray roll forming machine consistently report superior performance and ease of operation. This machine integrates intuitive controls, allowing operators, even those with minimal experience, to produce consistent results. The automation significantly reduces manual labor, minimizes errors, and enhances output quality. This level of usability underscores the machine’s design focused on operator comfort and productivity.

In terms of expertise, the technology employed in the outdoor cable tray roll forming machine represents the pinnacle of roll forming engineering. The machine is equipped with a series of high-precision rollers that custom-shape flat metal sheets into intricately detailed cable trays. Its programmable logic controllers (PLCs) offer exceptional customization, allowing users to adjust parameters such as tray width and depth, which empowers businesses to tailor products to meet specific requirements.

The manufacture of the outdoor cable tray roll forming machine involves the collaboration of engineers and industry experts who ensure that each unit meets stringent quality standards. These experts remain at the forefront of roll forming technology, continuously refining the design and function of the machine to improve performance and extend its application. Their profound understanding of metallurgy and mechanical processes fortifies the machine’s ability to handle a variety of metals, including stainless steel and galvanized iron, which are preferred for outdoor installations due to their corrosion resistance.

outdoor cable tray roll forming machine

From an authoritative perspective, the credibility of the outdoor cable tray roll forming machine is reinforced by numerous industry certifications and endorsements. Manufactured by leading engineering firms, these machines adhere to international safety and quality guidelines, thus reinforcing their place as a trusted solution for cable tray production. The machine’s reliability is further validated through comprehensive testing, which ensures that components are durable and capable of maintaining performance over prolonged use.

Trustworthiness of this machinery can also be measured by its widespread adoption across industries that demand high standards of equipment performance. Users have lauded the consistency of the cable trays produced by these machines, noting that their precise dimensions and robust construction reduce installation time and overall project costs. The traceability of materials and adherence to environmental regulations contribute to a reputation for eco-friendly production practices, which resonates with companies that prioritize sustainability.

The financial impact of utilizing an outdoor cable tray roll forming machine is notable.

Companies experience reduced overheads due to decreased waste and increased efficiency. This machine allows for an on-demand production model, minimising excess inventory and improving cash flow. Its adaptability to varied project scales also means that businesses can easily adjust output to align with market demands, providing a strategic advantage over traditional manufacturing methods.

In conclusion, the outdoor cable tray roll forming machine exemplifies the synergy of experience, expertise, authority, and trustworthiness. Its innovative design and operational efficiency redefine cable tray production, catering to the stringent needs of outdoor applications while upholding high standards of quality and reliability. This machine is not just an investment in equipment; it is an investment in precision, proficiency, and long-term business success. As industries continue to evolve and infrastructure demands continue to rise, the relevance and necessity of such advanced machinery will undeniably become even more pronounced.