Understanding MS Tube Mills A Comprehensive Overview

The MS Tube Mill, or Mild Steel Tube Mill, is an essential piece of equipment in the manufacturing industry, especially in the production of seamless and welded tubes. This machinery plays a crucial role in converting flat steel strips or coils into various tubular products that serve multiple purposes across different sectors, including construction, automotive, and furniture.

The Process

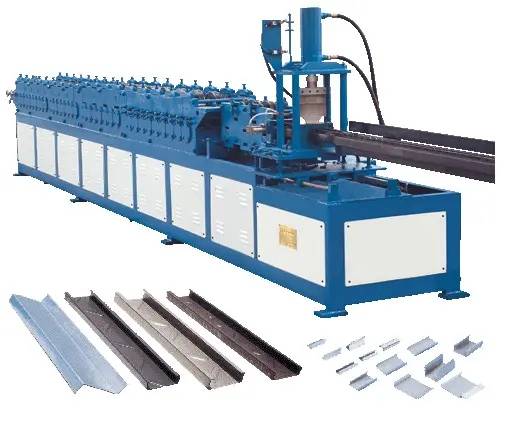

The operation of an MS tube mill begins with feeding the steel coil into the entry section of the mill. At this stage, the coil is uncoiled and flattened to prepare it for the forming process. Once flattened, the steel strip is introduced to a series of forming rollers that gradually shape it into a cylindrical form. This forming process is often referred to as the tube forming process.

Following the forming, the edges of the strip are joined together, typically through a welding process. There are two primary welding techniques used in MS tube mills High-Frequency Induction (HFI) welding and Electric Resistance Welding (ERW). HFI welding allows for quicker and more efficient processes, while ERW is known for its strength and reliability. The choice of welding method largely depends on the type of end product required and the specifications set by the clients.

Understanding MS Tube Mills A Comprehensive Overview

Applications

MS tubes find extensive applications in numerous industries. In the construction sector, they are used for scaffolding, structural support, and framework. In the automotive industry, mild steel tubes serve as critical components in chassis and exhaust systems. Moreover, the furniture industry utilizes these tubes to create various furnishings, including chairs and tables. The versatility and adaptability of MS tubes make them an integral part of modern manufacturing processes.

Advantages

One of the significant advantages of using MS tube mills is their efficiency in producing tubes at a large scale while maintaining high quality. The precision of modern mills has advanced significantly, allowing manufacturers to produce tubes with exact specifications. Additionally, mild steel is a cost-effective material compared to other metals, making it attractive for various applications.

Furthermore, the recyclability of mild steel contributes to its popularity. Sustainable manufacturing practices are more critical than ever, and the ability to recycle steel reduces waste and promotes environmental responsibility.

Conclusion

In summary, MS tube mills represent a vital technology that underpins countless industries worldwide. From their efficient production process to their broad range of applications, these mills are a testament to the advancements in manufacturing technology. As industries continue to evolve and adapt to new challenges and demands, the role of MS tube mills will likely become even more crucial in delivering high-quality solutions to meet the needs of various sectors.