Understanding Angle Roll Forming Machines

Angle roll forming machines are essential tools in the metalworking industry, specifically designed for the efficient and precise bending of metal into angular shapes, such as L, U, and T beams. These machines utilize a series of powered rolls to deform metal sheets or sections into various angles and dimensions, making them indispensable for manufacturers involved in construction, automotive, and furniture production.

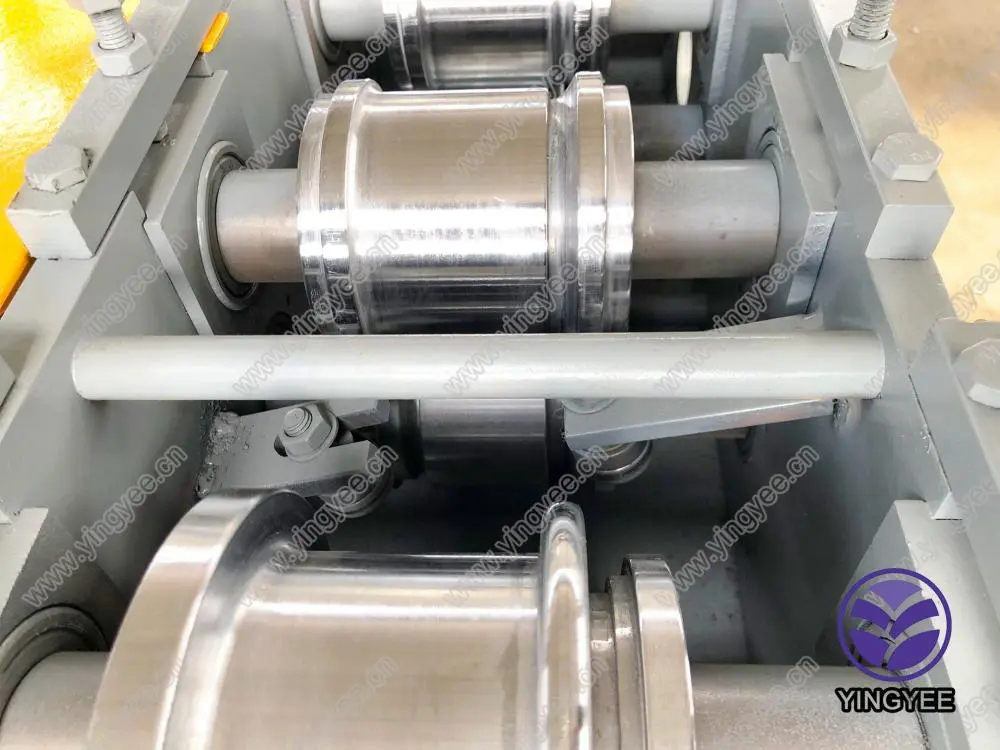

One of the primary advantages of angle roll forming machines is their ability to produce uniform angles with high precision. The process begins with the raw metal being fed through the machine, where it passes between three rolls. By adjusting the position of these rolls, operators can manipulate the metal's shape gradually. This process allows for consistent production runs, ensuring that each piece meets specified tolerances while minimizing waste.

Different types of angle roll forming machines exist to cater to diverse applications and materials. Manual machines are typically used for lighter materials and simpler bending tasks, while hydraulic and CNC-controlled machines cater to heavier pieces and more complex designs. The latter type offers the versatility of programming, enabling users to create intricate shapes and allowing increased productivity through automation.

In addition to flexible design capabilities, angle roll forming machines contribute to improved efficiency in manufacturing processes. The quick setup and short production times reduce labor costs and enhance production rates. Moreover, the use of durable materials in these machines ensures longevity and reduced maintenance, making them a reliable investment for businesses.

Another significant aspect of angle roll forming machines is their role in sustainable manufacturing. By utilizing advanced technology and optimizing metal usage, these machines help reduce scrap material. Efficient processing means that more products can be made from less raw material, aligning manufacturers with environmentally conscious practices.

The versatility of angle roll forming machines also extends to their application across various industries. In construction, they are widely used for fabricating structural components that support buildings and bridges. In the automotive sector, they play a critical role in producing parts like chassis and frame structures. Moreover, in the furniture industry, manufacturers rely on these machines to create aesthetically pleasing and functional designs.

In conclusion, angle roll forming machines are vital in the modern manufacturing landscape, providing precision, efficiency, and versatility. Their ability to adapt to different materials and applications makes them an invaluable asset, ensuring that businesses can meet the ever-evolving demands of the market while adhering to sustainable practices. As technology continues to advance, these machines will undoubtedly become even more integral to the production processes across various industries.