Metal Stud Roll Forming Machine Revolutionizing Construction

In the ever-evolving world of construction, efficiency and precision are key components that determine the success of any project. One technological advancement that has significantly impacted the industry is the metal stud roll forming machine. This innovative equipment has transformed the way metal studs are produced, leading to faster construction times, lower costs, and enhanced structural integrity.

What is a Metal Stud Roll Forming Machine?

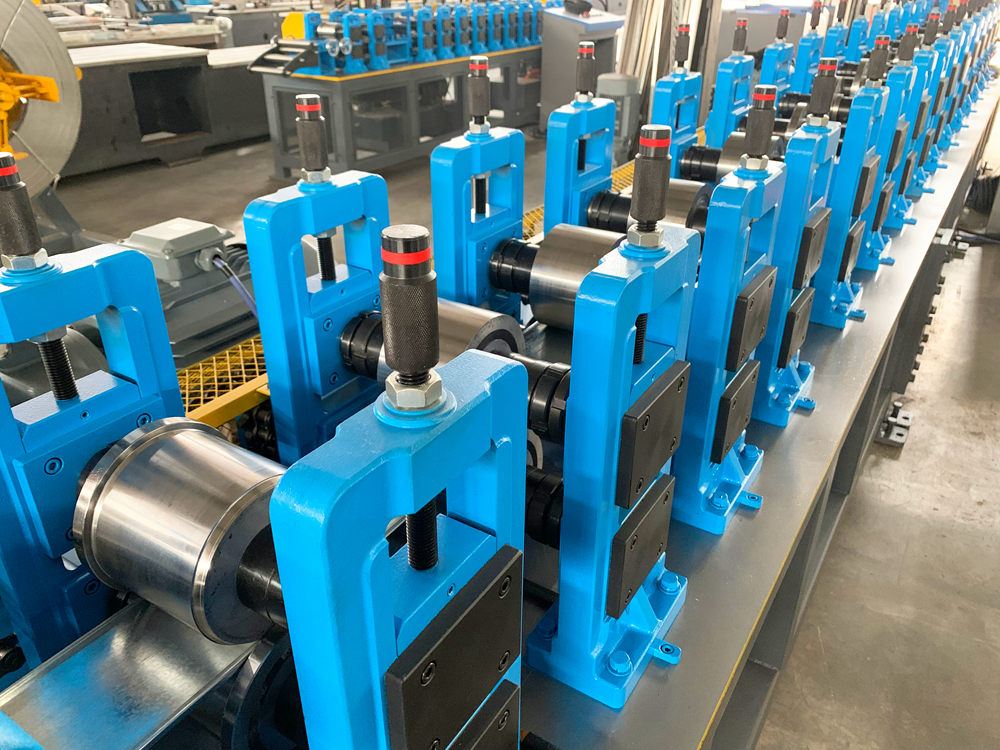

A metal stud roll forming machine is a specialized piece of machinery designed to create metal studs used in framing buildings. The process begins with feeding a flat steel coil into the machine, which then transforms it into a pre-defined profile through a series of forming stations. These stations bend and shape the metal until it reaches the desired dimensions and specifications.

The versatility of roll forming machines allows for a variety of profiles, accommodating different sizes and shapes of studs. This can cater to diverse construction requirements, from residential buildings to large commercial structures.

Benefits of Metal Studs

Metal studs have become increasingly popular compared to traditional wood framing. They offer numerous advantages, including

1. Durability Metal studs are not susceptible to warping, splitting, or decay, making them an ideal choice for various environmental conditions. 2. Fire Resistance Being non-combustible, metal studs enhance the fire resistance of a building, providing an added layer of safety.

3. Pest Resistance Metal framing eliminates concerns about termites and other wood-destroying pests, ensuring longevity.

5. Sustainability Metal studs are often made from recycled materials and are themselves recyclable, contributing to environmentally friendly building practices.

The Roll Forming Process

The process initiated by the metal stud roll forming machine is automated and highly efficient. After the steel coil is loaded, it passes through a series of rollers that shape the metal into the desired profile. The machine can operate at high speeds, producing large quantities of studs in a relatively short time.

Additionally, modern roll forming machines come equipped with advanced features such as digital controls and programmable settings. This allows operators to adjust the settings quickly for different profiles or specifications, optimizing production efficiency.

Moreover, these machines can include cutting stations that cut the formed metal studs to the required lengths. This streamlining of the production process minimizes waste and reduces manual handling, further speeding up project timelines.

Applications in the Construction Industry

Metal studs produced by roll forming machines are widely used in various applications within the construction industry. They are commonly employed in

- Commercial Buildings For office spaces, retail outlets, and warehouses, where durability and fire safety are paramount. - Residential Projects Many modern homes utilize metal framing due to its strength and resilience. - Interior Partitions Metal studs are often used to create non-load bearing walls, ceilings, and other structural elements within a building. The versatility of metal stud framing allows architects and builders to design innovative structures capable of withstanding extreme weather conditions while optimizing space.

Conclusion

The introduction of the metal stud roll forming machine has revolutionized the construction industry. With its ability to streamline production, enhance precision, and offer a sustainable building solution, it has become an essential tool for modern construction projects. As the industry continues to evolve, the adoption of such advanced machinery will play a crucial role in meeting the increasing demands for efficiency, safety, and sustainability in construction practices. The metal stud roll forming machine is not just a piece of equipment; it is a catalyst for change in how we build our world.