The Importance of C and Z Purlin Machines in Modern Construction

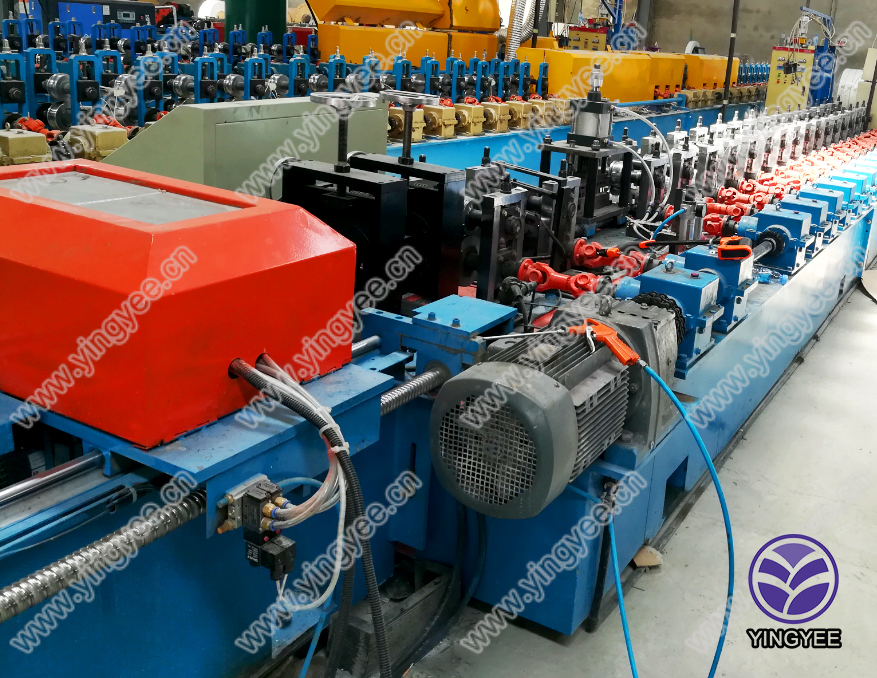

In the realm of modern construction, the efficient use of materials and advanced technology is essential for meeting the demands of speed, quality, and cost-effectiveness. One of the key innovations that have emerged in recent years is the C and Z purlin machine. This equipment plays a crucial role in the production of C and Z shaped steel purlins, which are widely used in various structural applications.

The Importance of C and Z Purlin Machines in Modern Construction

The primary advantage of a C and Z purlin machine is its ability to streamline the manufacturing process. Traditionally, the production of purlins involved manual labor and time-consuming techniques. However, with the advent of modern purlin machines, manufacturers can now produce purlins with high precision and at an impressive speed. These machines utilize computer numerical control (CNC) technology to ensure that each purlin is manufactured to exact specifications. This level of accuracy reduces material waste and enhances the overall quality of the final product.

Another significant benefit of C and Z purlin machines is their automation capabilities. Operators can input specific dimensions and shapes into the machine’s software, allowing it to automatically adjust and produce purlins according to the project requirements. This feature not only saves time but also minimizes human error, leading to a consistently high standard of production. Furthermore, the ability to produce both C and Z profiles on the same machine adds to the versatility and efficiency of the equipment.

In terms of economic impact, the implementation of C and Z purlin machines can significantly reduce labor costs and production time. Manufacturers can achieve higher output levels, catering to an increased demand for steel structures in the fast-paced construction industry. Additionally, by producing lightweight yet strong purlins, builders can enhance the overall efficiency of their projects, leading to cost savings and improved timelines.

Sustainability is another vital aspect of modern construction that C and Z purlin machines contribute to. Steel is a recyclable material, and utilizing purlins made from high-quality steel can lead to more sustainable building practices. Manufacturers are increasingly adopting green technologies and processes, further reducing their environmental footprint and promoting responsible sourcing and manufacturing practices.

In conclusion, C and Z purlin machines are instrumental in revolutionizing the construction industry. Through automation, precise manufacturing, and economic efficiencies, they not only enhance the quality of purlins but also contribute to more sustainable building practices. As the demand for steel structures continues to grow, the role of these machines will undoubtedly become even more critical in meeting future construction challenges. By investing in advanced purlin machines, manufacturers are positioning themselves at the forefront of an evolving industry, ready to capitalize on new opportunities and innovations.