The Advancements in Metal Roofing Tile Machines

In the evolving world of construction and architecture, metal roofing has become increasingly popular due to its durability, aesthetic appeal, and energy efficiency. This trend has led to significant advancements in the machinery used for producing metal roofing tiles. Metal roofing tile machines are specialized tools designed for the manufacturing of various metal roofing products. The growth of the construction industry has initiated a surge in demand for these machines, revolutionizing their functionality and efficiency.

One primary advantage of metal roofing is its resilience. Metal roofs can withstand extreme weather conditions, making them a favorable choice in regions prone to heavy rainfall, snowfall, or high winds. The production of metal roofing tiles has become highly sophisticated, with machines designed to create tiles that mimic the look of traditional roofing materials, such as shingles and slate, while providing the enhanced performance of metal.

Metal roofing tile machines are capable of producing tiles of varying shapes, sizes, and styles, catering to the diverse aesthetic preferences of consumers. This versatility is achieved through advanced technology, including computer numerical control (CNC) systems, which allow for precise and consistent production. CNC technology enables manufacturers to customize roofing tiles according to specific project requirements, therefore increasing efficiency and reducing waste.

In addition to customization, modern metal roofing tile machines emphasize rapid production capabilities. Many machines are designed to operate at high speeds, producing a large volume of tiles in a shorter time frame. This efficiency is essential for contractors looking to complete projects promptly without compromising quality. Advanced automation also plays a significant role in streamlining the manufacturing process, from initial coil handling to the final inspection of finished products.

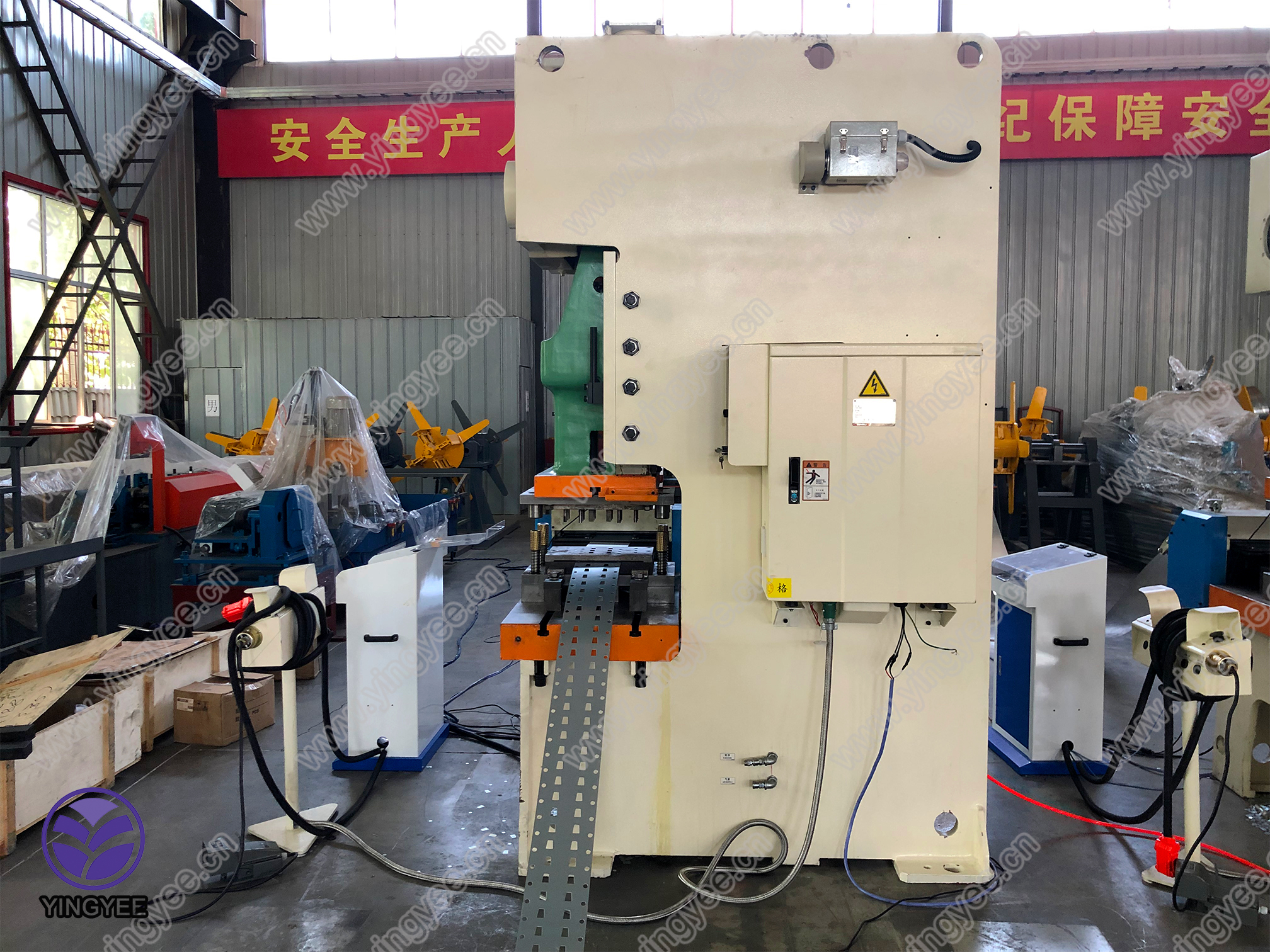

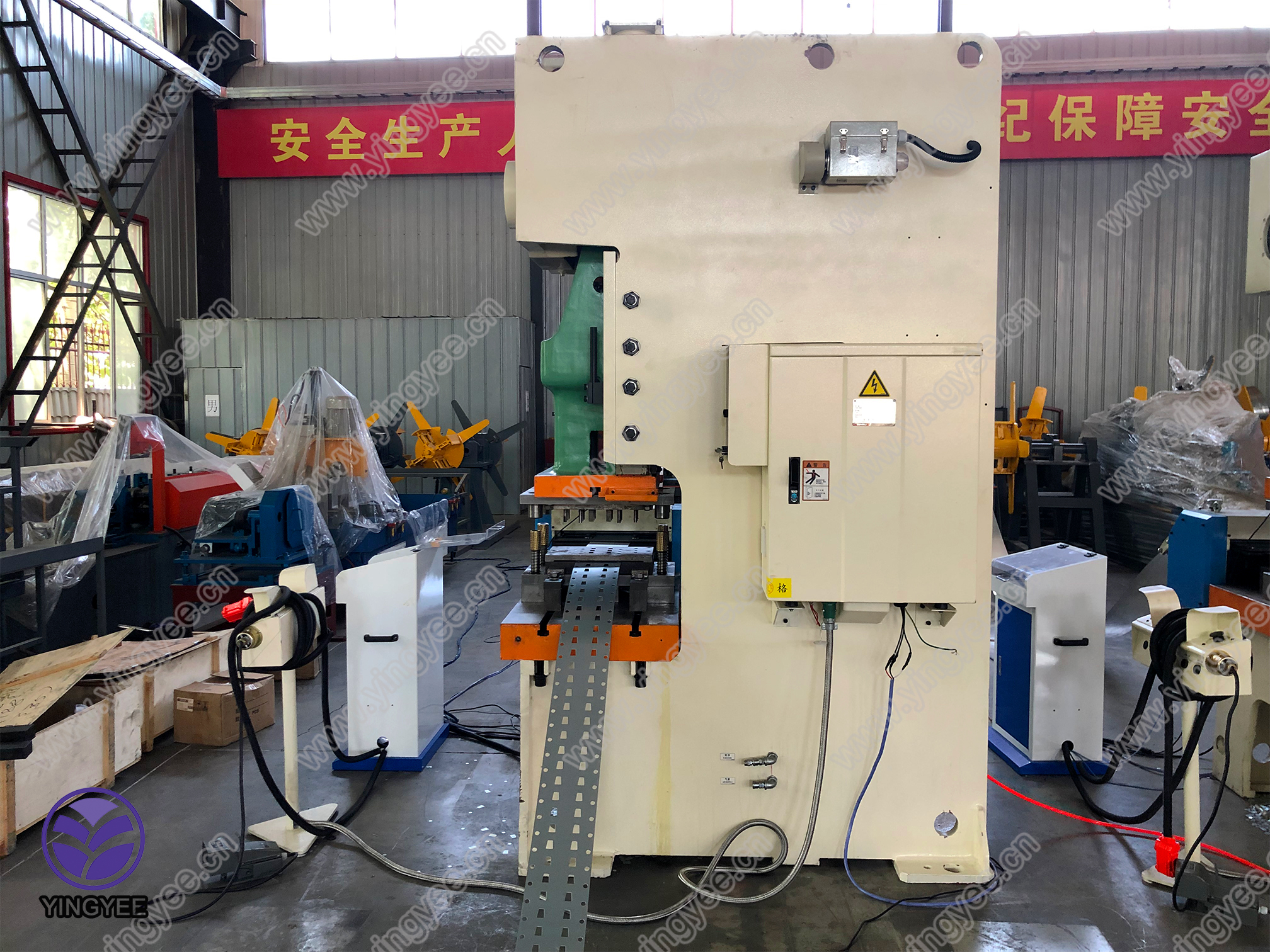

metal roofing tile machines

Moreover, technological innovations have also focused on enhancing the durability and quality of produced tiles. Many machines are equipped with features that ensure proper coating and finishing techniques, which protect metal roofing tiles from corrosion and other environmental factors. For instance, machines can apply high-quality finishes that not only improve the aesthetic appeal but also extend the longevity of the roofing materials.

Sustainability is another vital aspect of modern metal roofing tile production. Many manufacturers are increasingly incorporating eco-friendly practices and materials into their processes. Metal roofing is inherently recyclable, and advancements in machine technology have made it easier to use recycled materials in production. This has not only reduced the carbon footprint of the manufacturing process but also aligns with the growing demand for sustainable building solutions.

The market for metal roofing tile machines is expanding globally, driven by the rising popularity of metal roofs and the need for efficient manufacturing solutions. As more construction projects embrace metal roofing, manufacturers are responding with innovative designs and functionalities that optimize production.

In conclusion, the advancements in metal roofing tile machines represent a remarkable intersection of technology and construction. These machines are not only enhancing the efficiency and quality of roofing tile production but also paving the way for sustainable building practices. As the demand for metal roofing continues to rise, it is imperative for manufacturers to keep innovating, ensuring that they can meet the diverse needs of the market while contributing to a more sustainable future in construction. The evolution of these machines is a testament to the industry's commitment to quality, efficiency, and environmental stewardship, setting the standard for future developments in the building materials sector.