Exploring the Mesh Wire Welding Machine A Game Changer for Chicken Cage Production

In the ever-evolving world of poultry farming, efficient production methods are crucial for ensuring the health of livestock and the sustainability of businesses. One of the most significant advancements in this field is the mesh wire welding machine, a cutting-edge technology that has transformed the way chicken cages are manufactured. This machine is not only vital for producing sturdy and reliable chicken cage panels but also contributes to the overall well-being of chickens raised in captivity.

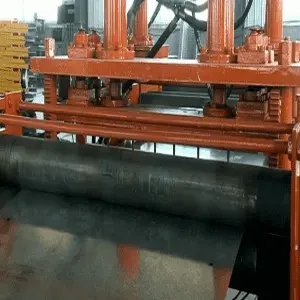

What is a Mesh Wire Welding Machine?

A mesh wire welding machine is an automated device designed to weld wire strands together, forming a robust mesh structure. This machine operates by feeding wire into the welding points, where an electrical current creates heat sufficient to fuse the wires. The result is a high-strength wire mesh that can withstand various environmental stresses. This technology is especially beneficial for producing chicken cage panels, which require durability and reliability.

Advantages of Using a Mesh Wire Welding Machine

1. Efficiency and Speed Traditional methods of creating wire mesh are often labor-intensive and time-consuming. The mesh wire welding machine significantly reduces production time, which is crucial for meeting the high demand in the poultry industry. With its high-speed capabilities, it can produce a large number of panels within a short timeframe, enabling businesses to scale their operations quickly.

2. Consistent Quality One of the standout features of the mesh wire welding machine is its ability to maintain consistent quality across all products. Automated welding reduces human error, ensuring that every weld is strong and uniform. This consistency is vital for the integrity of chicken cages, which must withstand the weight of the birds and provide a safe environment.

3. Cost-Effectiveness Investing in a mesh wire welding machine can lead to significant long-term savings. While the initial purchase cost may be high, the efficiency, speed, and reduced labor costs associated with automation lead to lower operational expenses. Moreover, the durability of the panels produced means fewer replacements and repairs over time.

4. Customizability Modern mesh wire welding machines come equipped with advanced technology that allows for customization. Manufacturers can easily adjust the specifications of the wire mesh, such as the size of the openings and the thickness of the wire. This flexibility enables poultry farmers to create cages tailored to their specific needs, accommodating different breeds of chickens or varying housing conditions.

5. Enhanced Safety and Welfare By producing sturdy and safe cages, mesh wire welding machines indirectly enhance the welfare of the animals housed within them. High-quality cages reduce the risk of injuries, provide proper ventilation, and ensure that chickens are comfortable. This not only benefits the animals but also promotes better growth rates and overall health, resulting in improved productivity for farmers.

The Impact on Poultry Farming

The introduction of mesh wire welding machines has had a significant impact on the poultry farming industry. As demand for poultry products continues to rise, the need for efficient and reliable production methods has never been more pressing. By utilizing these machines, poultry farmers can not only increase their output but also improve the conditions under which their chickens are raised.

The integration of technology in agriculture is becoming increasingly important, and the mesh wire welding machine is a prime example of how automation can lead to better outcomes. It facilitates the production of high-quality cages, supports animal welfare, and enables farmers to respond to market demands effectively.

Conclusion

In conclusion, the mesh wire welding machine is a revolutionary tool for the poultry farming sector. It enhances the efficiency of chicken cage production, ensures consistent quality, and ultimately contributes to the welfare of the animals. As more farmers recognize the benefits of this technology, it is likely to become a standard fixture in poultry operations worldwide. Embracing such innovations is crucial for meeting the challenges of modern agriculture and ensuring a sustainable future for poultry farming.