Understanding China's Roll Forming Machine Manufacturers

In recent years, China's manufacturing sector has experienced unprecedented growth, making it a critical player in the global marketplace. Among the various segments of manufacturing, roll forming technology has gained substantial attention due to its efficiency and versatility. China, with its vast array of roll forming machine manufacturers, has established itself as a hub for producing high-quality machinery used in various industries, including construction, automotive, and electrical.

What is Roll Forming?

Roll forming is a continuous bending process in which a long strip of metal is fed through a series of rollers to create a desired cross-sectional shape. The process is highly efficient and is preferred for producing long lengths of uniform sections, such as metal roofing, wall panels, and various structural components. The versatility and efficiency of roll forming make it an essential technique in modern manufacturing.

The Landscape of Roll Forming Machine Manufacturers in China

China boasts numerous roll forming machine manufacturers, ranging from small-scale enterprises to large corporations. The competitive landscape is characterized by a diverse range of companies that specialize in producing various types of roll forming machinery. These manufacturers often offer customized solutions to meet the specific needs of their clients, which can include unique design specifications and production requirements.

Many Chinese manufacturers are equipped with advanced technology, such as Computer Numerical Control (CNC) systems, which enhances the precision and efficiency of the roll forming process. These technological advancements enable companies to produce high-quality products at lower costs, which is a significant advantage in global competition.

Key Features of Chinese Roll Forming Machines

1. Customization Chinese manufacturers often provide customizable solutions, allowing clients to specify dimensions, materials, and design features according to their production needs. This flexibility is essential for businesses that require specialized components.

2. High Efficiency Roll forming machines produced in China are designed for high-speed operation, enabling users to increase production rates without sacrificing quality. This efficiency is crucial for industries that operate under tight deadlines.

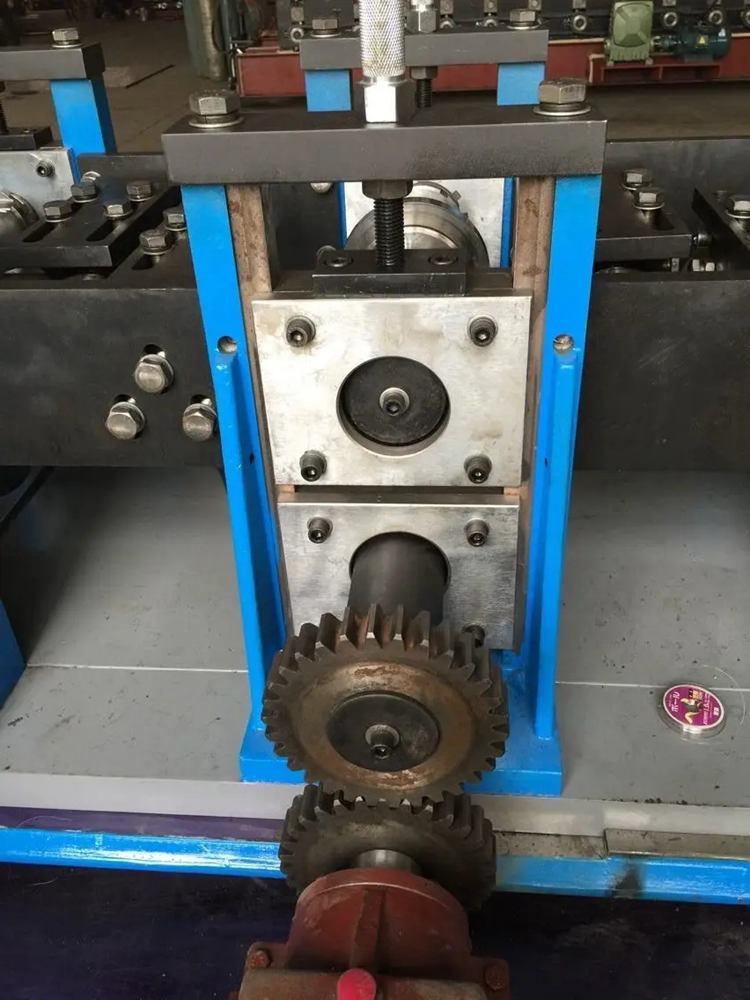

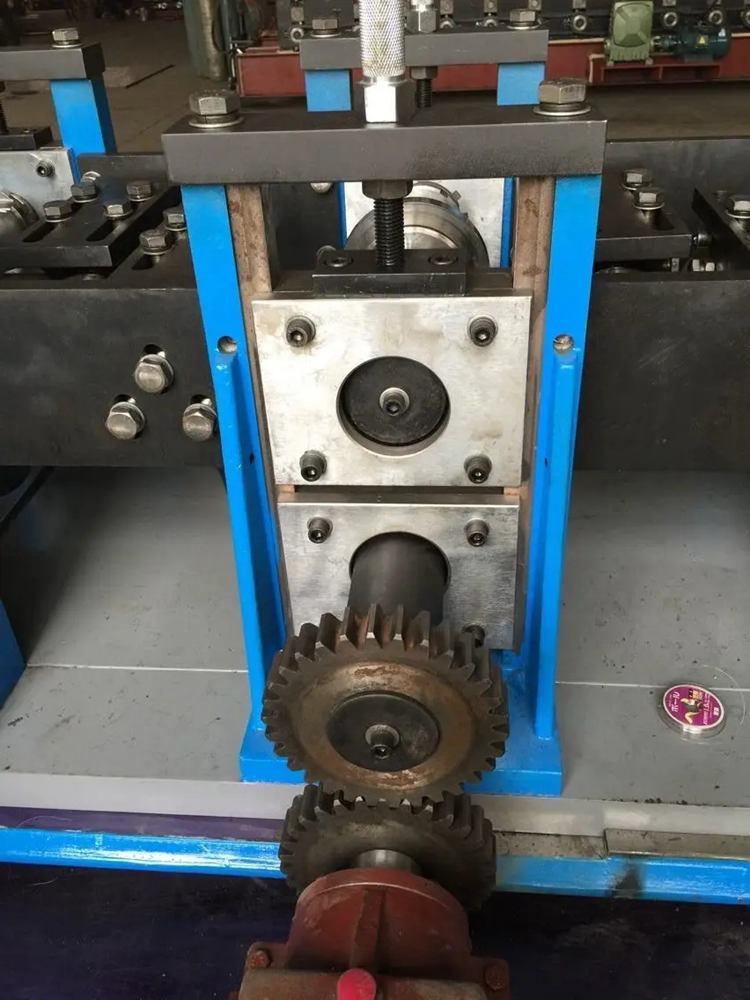

china roll forming machine manufacturers

3. Cost-effectiveness The manufacturing costs in China are generally lower compared to many Western countries, making it possible for companies to obtain high-quality roll forming machines at competitive prices. This cost advantage is appealing for both domestic and international businesses.

4. Technological Integration Many manufacturers are integrating digital technologies and automation into their roll forming machines. This integration not only enhances production efficiency but also improves the overall quality of the finished products.

5. After-sales Support Chinese roll forming machine manufacturers often offer comprehensive after-sales services, including installation, maintenance, and training. This support is crucial for ensuring that clients can operate their machines effectively and address any potential issues.

The Global Impact of Chinese Manufacturers

The rise of Chinese roll forming machine manufacturers has significantly impacted global production dynamics. By supplying cost-effective, efficient, and high-quality machinery, these manufacturers have enabled companies around the world to optimize their production processes. Many international businesses turn to Chinese suppliers for their roll forming machine needs, as they can achieve substantial cost savings while maintaining high standards of quality.

Challenges Faced by Manufacturers

While the opportunities are substantial, Chinese roll forming machine manufacturers also face challenges, including increasing competition both domestically and internationally. Additionally, the need for continuous innovation is critical, as technology is rapidly evolving. Manufacturers must adapt to these changes to remain competitive in the global market.

Moreover, concerns related to sustainability are becoming more pronounced. Manufacturers are being urged to adopt more eco-friendly practices and develop machinery that minimizes waste and energy consumption. Addressing these challenges will be vital for maintaining China's leadership in the roll forming machine industry.

Conclusion

China's roll forming machine manufacturers have become integral players in the global manufacturing landscape. Their ability to deliver high-quality, customizable, and cost-effective solutions has positioned them as preferred suppliers for companies across various industries. However, the path forward requires adaptation to technological advances and sustainability demands. As the industry evolves, Chinese manufacturers will need to continue innovating to maintain their competitive edge and meet the changing needs of the global market.