The Wall Angle Light Keel Forming Machine Revolutionizing Construction

In today's fast-paced construction industry, efficiency and precision are paramount. One of the innovations that have emerged to meet these demands is the wall angle light keel forming machine. This machine plays a crucial role in the creation of light steel frames, which are essential for various building projects, including residential and commercial properties. By streamlining the production of wall angle light keels, this machinery enhances the overall quality and speed of construction.

Understanding the Wall Angle Light Keel Forming Machine

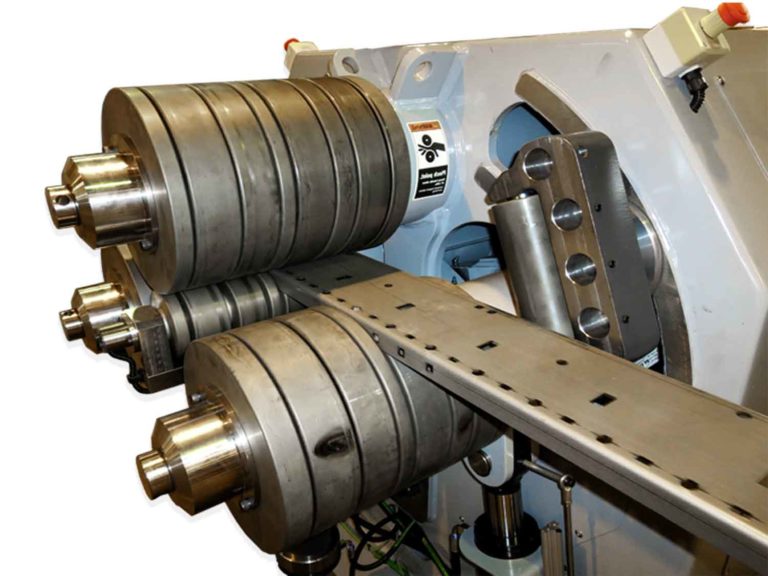

The wall angle light keel forming machine is designed to produce steel keels that serve as the backbone of suspended ceilings and interior wall systems. These keels are typically lightweight and made from galvanized steel, which provides strength without adding excessive weight to the overall structure. The machine operates by feeding flat steel strips into a series of rollers that gradually shape the material into the desired profile. This continuous forming process allows manufacturers to produce a high volume of keels with consistent dimensions and quality.

Key Features and Technology

One of the standout features of modern wall angle light keel forming machines is their automation and precision

. Many of these machines are equipped with advanced computer numerical control (CNC) systems, allowing for quick adjustments and customization based on specific project requirements. This level of precision reduces waste and minimizes the likelihood of errors during installation, ultimately leading to better overall project outcomes.Moreover, these machines are designed for efficiency. High-speed production capabilities enable manufacturers to keep pace with the increasing demand for steel framing solutions. The compact design of these machines also ensures that they occupy less floor space in factory settings, making them suitable even for small-scale operations.

Benefits to the Construction Industry

The introduction of the wall angle light keel forming machine has brought several key benefits to the construction industry. Firstly, the lightweight nature of the produced keels facilitates easier handling and installation. Construction crews can transport and manipulate these keels with greater ease, leading to reduced labor costs and faster project completion times.

Secondly, the durability and corrosion resistance of galvanized steel ensure that structures built with these keels will have a longer lifespan. This can translate to lower maintenance costs over the years, making light steel framing an attractive option for builders and developers.

Finally, the ability to produce customized keels quickly means that construction teams can adapt to design changes on-the-fly. This flexibility is crucial in today's construction environments, where project specifications can evolve and where fast-tracked timelines are often in demand.

Conclusion

In conclusion, the wall angle light keel forming machine represents a significant advancement in the construction sector, offering enhanced efficiency, precision, and flexibility. As the industry continues to evolve, the adoption of such innovative machinery will likely increase, leading to the development of safer, more durable, and cost-effective building solutions. The future of construction will undoubtedly be shaped by these technological advancements, making it easier for builders to meet the demands of modern architecture while maintaining high standards of quality and performance.