Understanding Tube Mill Machines

Tube mill machines are indispensable equipment in modern manufacturing, primarily used for producing steel tubes and pipes. They play a crucial role in various industries, including construction, automotive, and oil and gas. This article explores the function, components, and advantages of tube mill machines, as well as their applications in various sectors.

At its core, a tube mill machine specializes in fabricating tubes and pipes from metal strips or coils. The process starts when a flat metal strip is fed into the machine, where it is gradually shaped into a cylindrical tube. This transformation involves several key processes, including welding, sizing, and cutting. The end product can range from small-diameter tubes to large-diameter pipes, depending on the specifications required.

Components of a Tube Mill Machine

A typical tube mill machine comprises several essential components that work in harmony to produce high-quality tubes. These include

1. Uncoiler This unit unwinds the metal strip from a roll and feeds it into the mill.

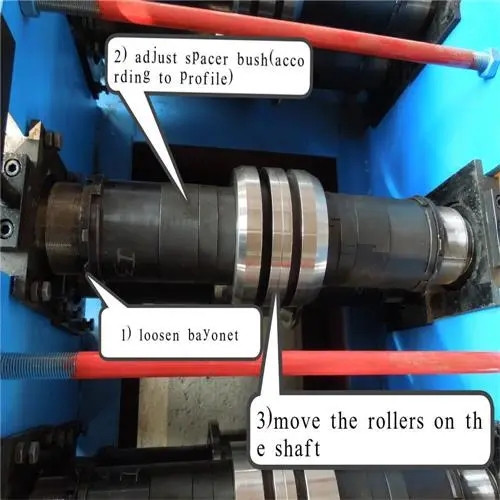

2. Forming Section This section consists of a series of rollers that progressively shape the flat strip into a cylindrical form.

3. Welding Unit Once the tube is formed, it is welded along the seam. This welding can be done using different methods, such as high-frequency induction welding or TIG welding, depending on the material and desired strength of the tube.

4. Sizing Section After welding, the tube passes through a sizing section where it is accurately shaped to the required dimensions.

5. Cutting Unit Finally, the finished tubes are cut to the desired lengths. This section can also incorporate various cutting technologies, including saw cutting or laser cutting.

6. Control System Modern tube mills are equipped with advanced control systems, allowing for precise operations and adjustments throughout the manufacturing process. Automation enhances efficiency and maintains consistent quality.

Advantages of Tube Mill Machines

The use of tube mill machines offers several advantages that contribute to their widespread adoption in the industry

- Versatility Tube mills can produce a diverse range of tube dimensions and types, making them suitable for different applications.

- Efficiency Automated tube mills can operate at high speeds, maximizing production rates and minimizing labor costs.

- Quality Control The continuous process of tube production allows for real-time monitoring and quality control, ensuring that the finished products meet industry standards.

- Cost-Effectiveness Although the initial investment in tube mill machines can be significant, the long-term savings in material waste and labor make them cost-effective tools for manufacturers.

Applications of Tube Mill Machines

The versatility of tube mill machines means they are used across various sectors. In the construction industry, they produce scaffolding tubes, structural tubes, and plumbing pipes. In the automotive sector, they are essential for creating exhaust pipes and chassis components. Additionally, the oil and gas industry relies on these machines for manufacturing pipes used in drilling and transportation.

In conclusion, tube mill machines are a cornerstone of modern manufacturing, facilitating the efficient production of tubular products across various industries. Their sophisticated design and technology enable manufacturers to produce high-quality tubes that meet diverse application needs. As industries continue to evolve, tube mill machines will undoubtedly adapt, offering innovative solutions for future manufacturing challenges.