Main Furring Roll Forming Machine An Overview

In the construction and building materials industry, the demand for efficiency, precision, and quality is ever-increasing. One of the key components that address these needs is the furring roll forming machine. This machine plays a crucial role in the production of metal furring channels, which are essential for drywall systems, ceilings, and various framing applications. Understanding what a main furring roll forming machine is and how it operates can provide valuable insights into its importance in modern construction practices.

What is a Furring Roll Forming Machine?

A furring roll forming machine is specialized equipment designed to produce continuous lengths of metal furring strips from coiled steel or aluminum. These strips serve as supportive frameworks for drywall installation and are essential in creating flat surfaces for attachment. The machine utilizes a series of rollers to shape the metal into the desired profile, ensuring uniformity and accuracy throughout the production process.

Key Features and Components

The main furring roll forming machine typically consists of several critical components

1. Uncoiler This device feeds the metal coil into the machine. It unwinds the coil steadily and maintains tension to prevent slack during the forming process.

2. Roll Forming System A series of rollers configured in a specific sequence takes the flat metal strip and progressively shapes it into the furring profile. The rollers are precisely engineered to ensure that the bends, angles, and dimensions meet industry standards.

3. Cut-off Mechanism After the desired length of furring strips is reached, the cut-off mechanism precisely trims the strips, allowing for easy handling and installation.

4. Control System Modern furring roll forming machines are equipped with advanced control systems, often utilizing programmable logic controllers (PLCs). These systems enable operators to adjust parameters such as speed, length, and thickness of the strips, ensuring flexibility and efficient production.

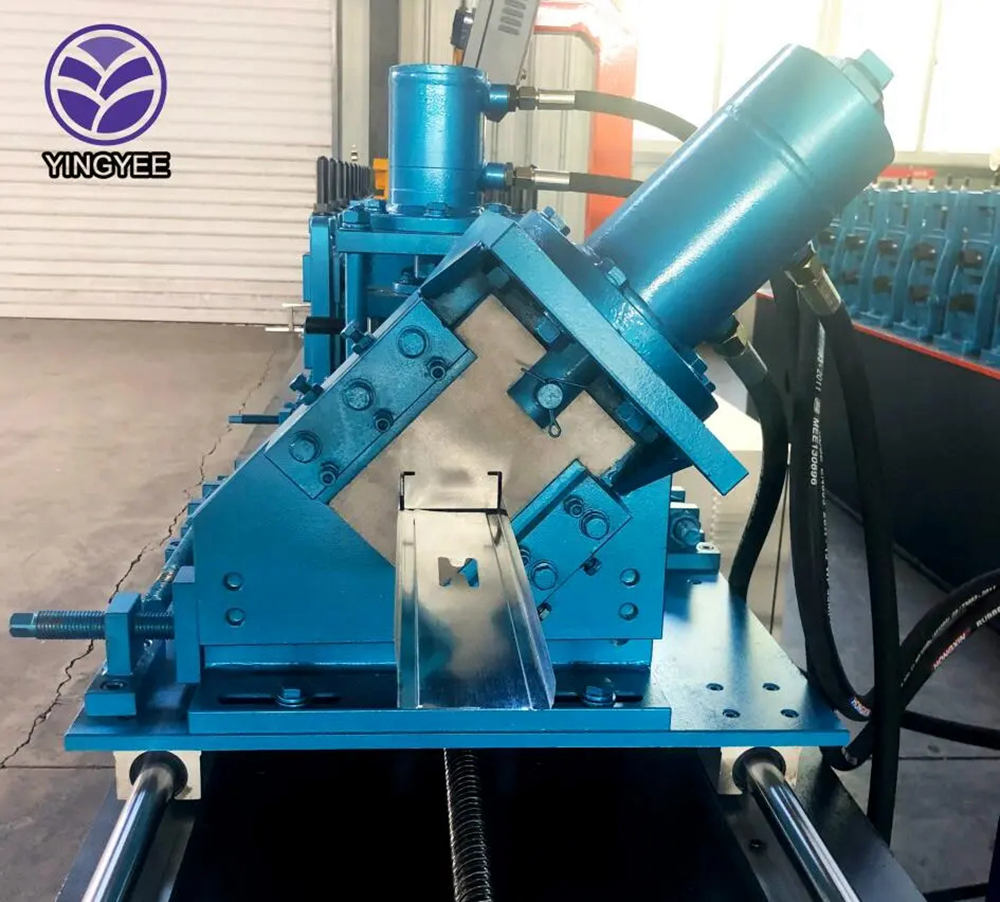

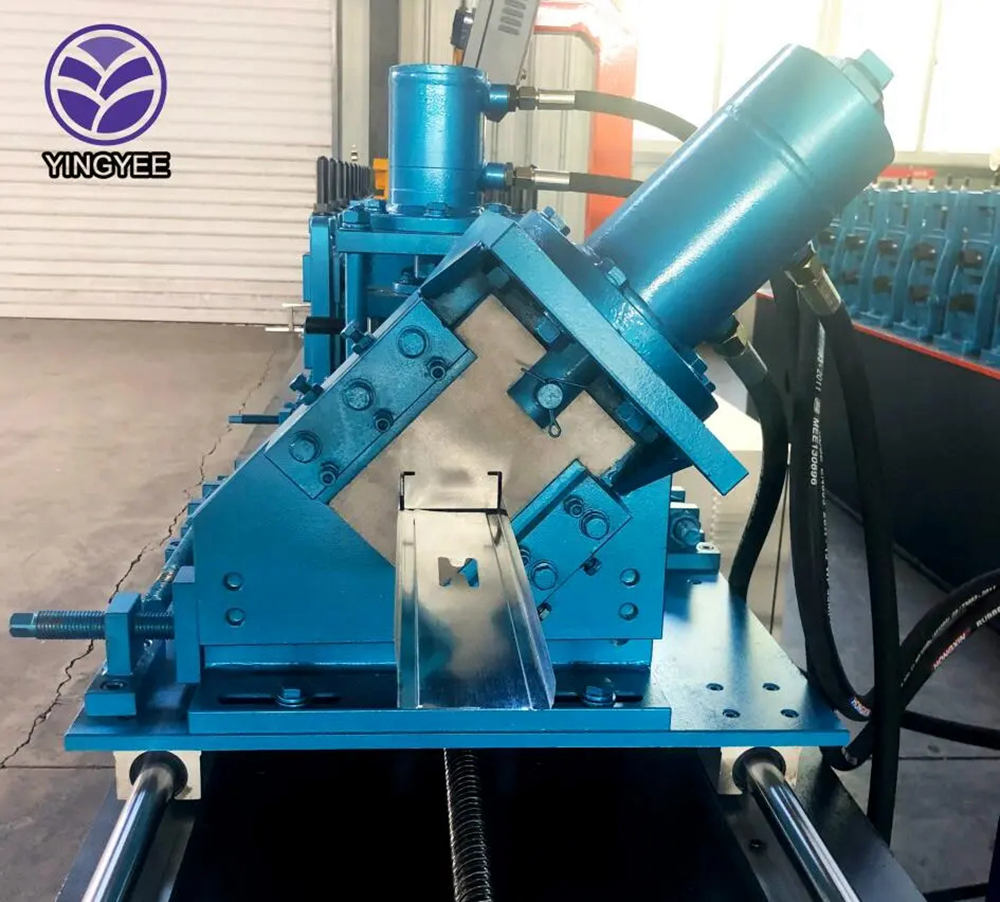

main furring roll forming machine

Benefits of Using a Furring Roll Forming Machine

The advantages of using a furring roll forming machine in the construction industry are manifold

- Efficiency The automated nature of roll forming significantly speeds up the production process compared to traditional methods, allowing manufacturers to produce large quantities of furring strips in a shorter time.

- Precision The consistent application of precision engineering ensures that every strip produced meets exact specifications, which is crucial for proper installation and structural integrity.

- Material Utilization Roll forming is known for its efficient use of materials. The continuous process minimizes waste, reducing costs and environmental impact during production.

- Versatility Furring roll forming machines can be adapted to produce various profiles and sizes, making them suitable for different construction applications and allowing manufacturers to cater to a wide range of customer needs.

Applications in Construction

Furring channels produced by these machines are integral in the drywall system, which is widely used in residential and commercial constructions. They provide the necessary structure for attaching drywall sheets, ensuring that walls and ceilings are flat and secure. Additionally, furring strips can be used to create space for insulation, electrical wiring, and plumbing, enhancing the overall functionality of the building.

Conclusion

The main furring roll forming machine is an indispensable tool in the modern construction industry, streamlining the production of essential framing components. Its efficiency, precision, and versatility make it a key player in ensuring high standards of quality and performance in building applications. As the construction industry continues to evolve, the importance of such machines will only grow, paving the way for innovative building practices and sustainable construction methods.