Sheet Roll Forming Machine A Key Technology in Modern Manufacturing

In the landscape of modern manufacturing, efficiency and precision are paramount. One of the critical tools that have emerged to meet these demands is the sheet roll forming machine. This technology plays an essential role in the construction and automotive industries, producing high-quality metal components with remarkable consistency and speed.

Understanding Sheet Roll Forming

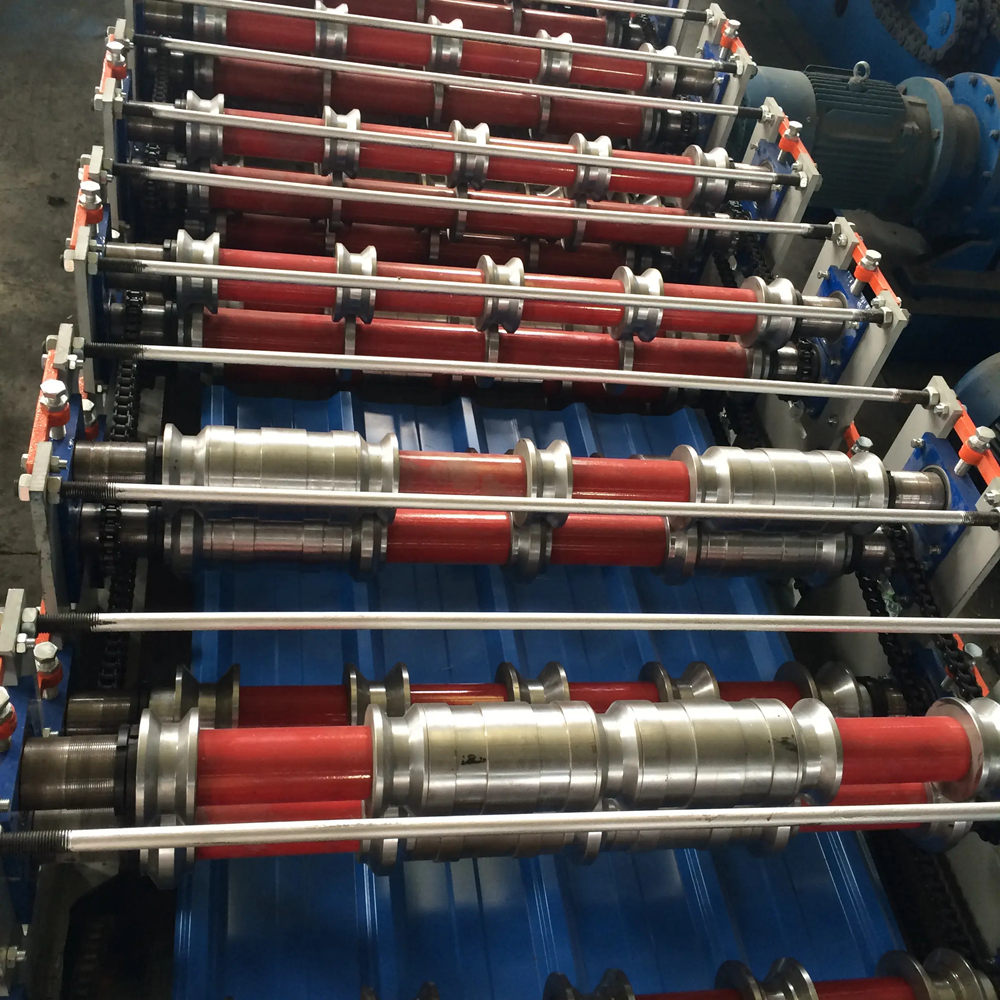

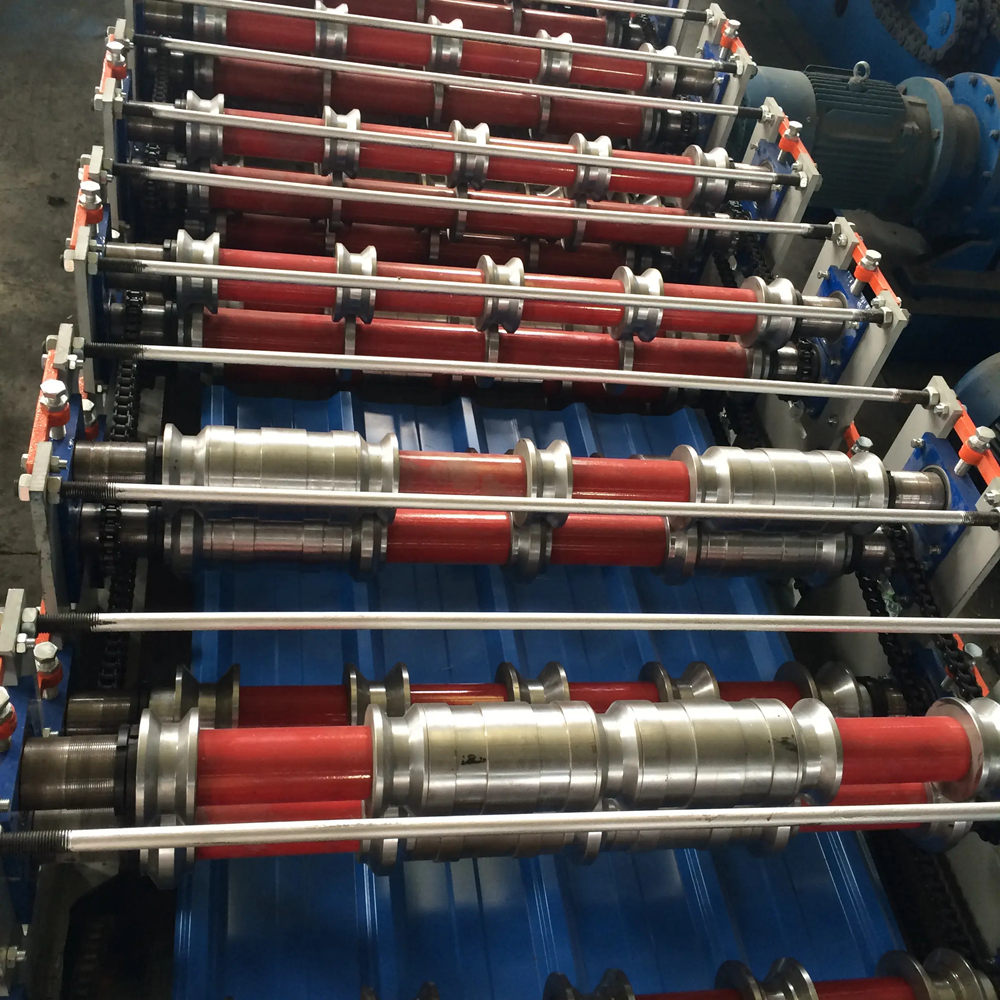

Sheet roll forming is a continuous process that converts flat sheets of metal into specific profiles through a series of rollers. The machine is designed to bend and shape the material while maintaining its structural integrity. The process begins with a flat sheet of metal, typically steel or aluminum, which is fed into the machine. As the sheet passes through a series of rollers, it is progressively shaped into the desired profile. The rollers can be configured to produce a wide variety of shapes, including C-sections, Z-sections, and other custom profiles.

One of the most remarkable aspects of roll forming is its ability to produce long lengths of product with minimal waste. Unlike traditional cutting methods, which can generate significant scrap material, roll forming maximizes the use of the starting sheet, making it a cost-effective solution for producing components in bulk.

Advantages of Sheet Roll Forming Machines

1. High Efficiency Roll forming machines operate at high speeds, allowing manufacturers to produce large quantities of products in a short time. This efficiency is a significant advantage in industries where demand is high and production needs to be streamlined.

2. Consistency and Precision The automated nature of roll forming ensures that each piece produced is uniform and meets precise specifications. This consistency is crucial in applications where components must fit together seamlessly, such as in the automotive and construction sectors.

sheet roll forming machine

3. Versatility Sheet roll forming machines can be adapted to create a wide range of profiles and designs. This versatility enables manufacturers to meet specific client requirements and innovate new product designs without extensive reconfiguration of equipment.

4. Material Savings By optimizing the use of raw materials, sheet roll forming reduces waste and lowers production costs. The process also allows for the use of thinner gauges of metal, which can lead to further material savings.

5. Minimal Maintenance Requirements Modern roll forming machines are engineered for durability and reliability. With proper maintenance, they can operate for extended periods without significant downtime, further enhancing productivity.

Applications of Sheet Roll Forming Machines

Sheet roll forming machines are utilized across various industries. In construction, they are used to produce roofing panels, gutters, and wall cladding, providing both structural integrity and aesthetic appeal. In the automotive industry, they manufacture components such as chassis, brackets, and other structural parts, vital for vehicle safety and performance.

As manufacturing technologies continue to evolve, the sheet roll forming machine is adapting to incorporate advancements such as automation and smart technology. The integration of computer numeric control (CNC) allows for real-time monitoring and adjustments during the forming process, ensuring even greater levels of precision and efficiency.

Conclusion

The sheet roll forming machine stands as a testament to the innovation in manufacturing technology, embodying the principles of efficiency, precision, and versatility. As industries strive to meet the challenges of a competitive market, the roll forming process will undoubtedly play a critical role in shaping the future of advanced manufacturing. With the ongoing development of new techniques and materials, the possibilities for sheet roll forming are endless, paving the way for a more efficient and innovative industrial landscape.