Step Tile Forming Machinery Revolutionizing Construction and Design

In the constantly evolving landscape of construction and architecture, the need for innovative solutions has never been more pressing. One such groundbreaking advancement is the advent of step tile forming machinery. Designed specifically for the production of high-quality step tiles, this machinery has proven essential for manufacturers aiming to meet the growing demand for durable and aesthetically pleasing flooring options.

Understanding Step Tile Forming Machinery

Step tile forming machinery is a specialized equipment designed to convert raw materials into step tiles—these tiles are often used for outdoor stairs, walkways, and other surfaces where enhanced grip and safety are paramount. The machinery typically employs a combination of molding and pressing techniques to shape and set materials such as concrete, providing a variety of textures and finishes to suit different architectural styles.

The machine operates through a streamlined process that begins with the preparation of the raw materials, which may include cement, sand, and various aggregates. Once mixed, the material is fed into the machine where it is poured into molds aligned with the desired tile design. The machinery then applies pressure and vibration to ensure the mixture fills all mold crevices perfectly, enhancing the density and durability of the final product. After curing, the tiles are removed from the molds and ready for finishing treatments, making them ready for installation.

Benefits of Using Step Tile Forming Machinery

One of the key advantages of step tile forming machinery is its efficiency

. Traditional tile-making processes can be labor-intensive and time-consuming, often resulting in inconsistent quality. However, with automated machinery, manufacturers can produce tiles at a significantly faster rate while maintaining uniformity in size and design. This efficiency translates to reduced production costs, enabling businesses to offer competitive pricing and meet tight project deadlines.

Moreover, the machinery allows for customization. Manufacturers can easily change molds to create tiles of various shapes, sizes, and finishes, accommodating the diverse needs of their clients. This flexibility is particularly beneficial in today's market, where custom designs are increasingly being sought after by architects and homeowners alike.

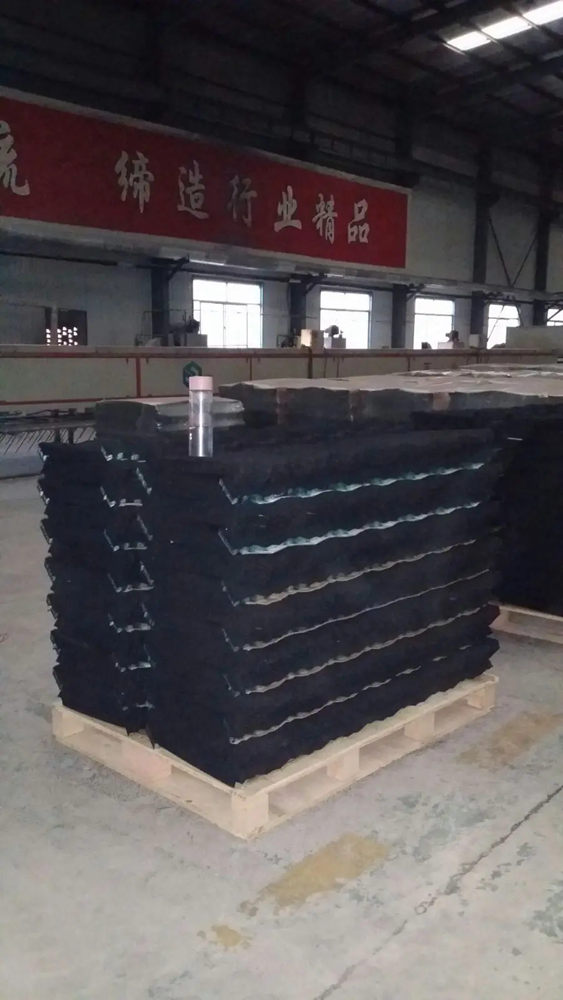

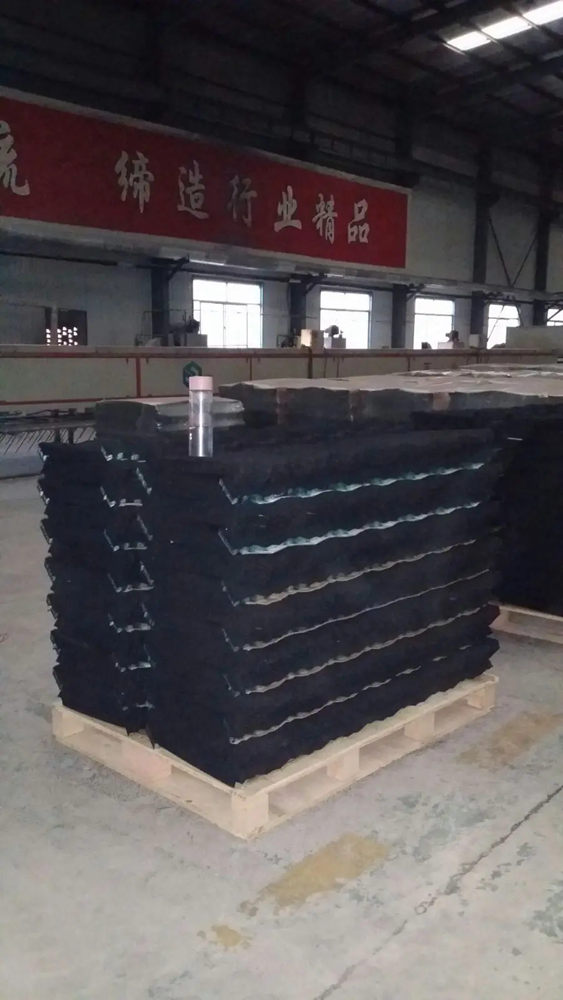

step tile forming machinery

Environmental Considerations

As the construction industry grapples with environmental challenges, step tile forming machinery can contribute to more sustainable practices. Many modern machines are designed to minimize waste, recycling excess materials and reducing the carbon footprint associated with tile production. By opting for eco-friendly materials or utilizing recycled aggregates, manufacturers can further enhance their sustainability credentials.

Applications and Market Demand

The applications for step tiles are extensive, ranging from residential home improvements to large-scale commercial projects. Given their durability and slip-resistant properties, they are ideal for public spaces, such as parks and plazas, where safety is a top priority. The growing trend toward outdoor living spaces is driving demand for visually appealing yet functional tiled areas, further highlighting the importance of high-quality step tile production.

As urbanization continues to accelerate globally, the need for efficient building materials remains critical. Step tile forming machinery not only addresses this demand but also aligns with the standards of modern design and functionality.

Conclusion

In conclusion, step tile forming machinery represents a significant advancement in the field of construction technology. By streamlining the tile production process, offering customization, and promoting sustainability, this machinery is a fundamental tool for manufacturers looking to innovate in a competitive marketplace. As the construction industry continues to evolve, the role of such machinery will likely become even more central, driving the creation of durable, aesthetically pleasing environments for tomorrow’s urban spaces.