Long Span Roll Forming Machines Revolutionizing Metal Fabrication

In the realm of metal fabrication, the demand for efficiency, precision, and versatility has led to the development of specialized machinery that meets these needs. One of the most significant innovations in this field is the long span roll forming machine. This equipment plays a crucial role in producing a variety of metal components used in numerous applications, such as construction, transportation, and manufacturing.

Understanding Long Span Roll Forming Machines

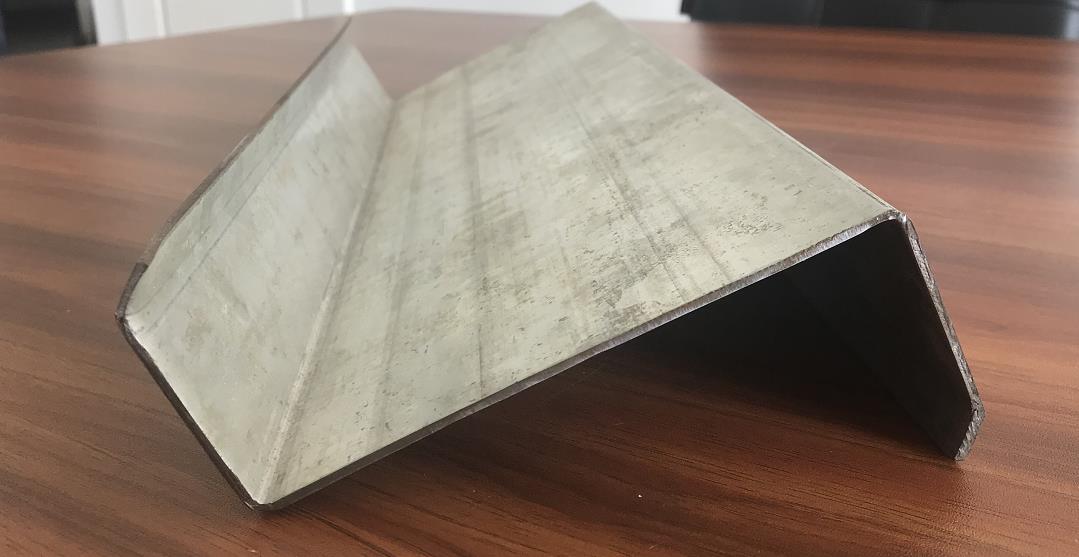

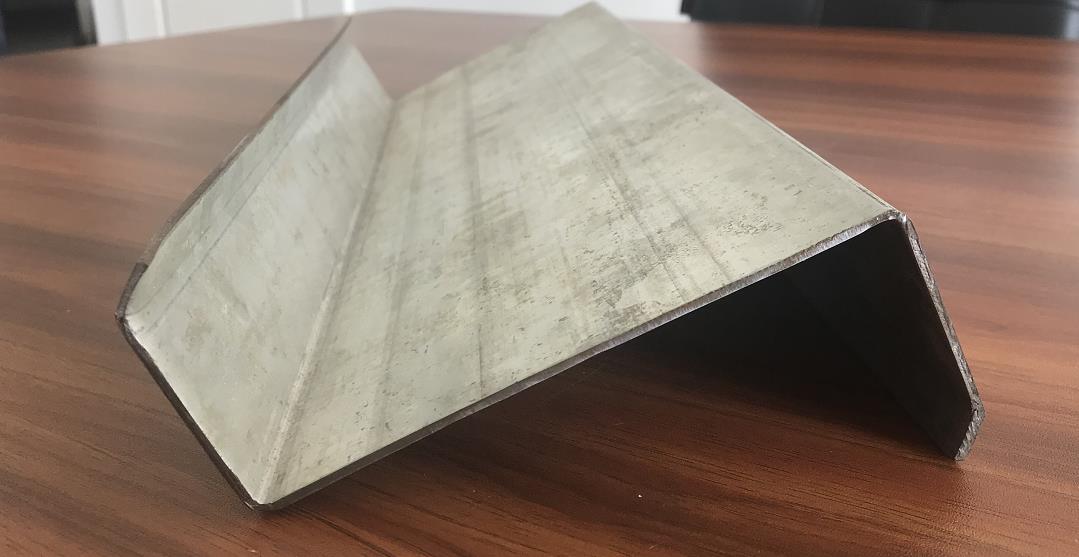

Long span roll forming machines are designed to continuously shape metal sheets into long, uniform profiles. Unlike traditional methods, which often require multiple operations and manual handling, roll forming offers a seamless production process. The machine consists of a series of rollers and forming stations that progressively shape the metal as it passes through. The advantage of this method is that it can produce long lengths of material with consistent cross-sectional profiles, which is particularly beneficial for modern construction projects that require longer structural components.

Key Features and Benefits

1. High Efficiency One of the primary benefits of long span roll forming machines is their ability to produce metal components quickly, significantly reducing manufacturing time. The continuous process minimizes interruptions, allowing for high-volume production.

2. Precision Roll forming machines provide exceptional dimensional accuracy. The process maintains uniform thickness and profile integrity, which is crucial for structural applications where safety and durability are paramount.

3. Versatility These machines can be adapted to produce a wide range of profiles, including Z-sections, C-sections, and even custom designs. This flexibility allows manufacturers to tailor their production to meet specific project requirements without investment in multiple dedicated machines.

long span roll forming machine

4. Material Savings Roll forming is highly efficient in terms of material usage. The process minimizes waste since metal sheets are precisely shaped with little to no trimming required. Furthermore, the ability to produce longer components reduces the need for welding, which can weaken the structure.

5. Automation and Integration Modern long span roll forming machines can be integrated with automated systems, such as feeding, cutting, and packaging. This full automation not only speeds up production but also improves workplace safety by reducing manual handling.

Applications Across Industries

Long span roll forming machines are utilized across various industries. In construction, they are integral to producing roof trusses, wall panels, and purlins, which form the backbone of steel buildings. In the automotive sector, these machines create components like chassis and structural supports that are essential for vehicle integrity. Additionally, they find applications in HVAC systems, where ducts and fittings must be produced with precision and low tolerances.

Future Trends

As industries evolve, so too does the technology behind roll forming machines. Innovations such as digital controls, smart sensors, and IoT integration are on the horizon, promising even greater efficiency and precision. Manufacturers are increasingly looking for eco-friendly solutions, and future designs may emphasize sustainability through energy-efficient operations and the use of recycled materials.

Conclusion

Long span roll forming machines represent a significant advancement in metal fabrication, combining efficiency, precision, and versatility into one powerful tool. Their ability to streamline production and reduce material waste makes them indispensable in various industries. As technology continues to advance, these machines will likely become even more vital to the future of manufacturing, shaping the way we produce and use metal components.