The Evolution and Significance of IBR Roofing Machines

In the realm of construction and building materials, the IBR (Inverted Box Rib) roofing machine has emerged as a game-changer, revolutionizing the way roofs are manufactured. With the growing demand for durable, cost-effective, and aesthetically pleasing roofing solutions, the importance of IBR roofing machines cannot be overstated.

Understanding IBR Roofing Profiles

IBR roofing sheets are characterized by their unique inverted box rib design, which provides enhanced strength and durability. The distinctive profile minimizes weight while maximizing load-bearing capacity. This makes IBR sheets suitable for a variety of applications, including industrial, commercial, and residential structures. Their interlocking design also offers superior weather resistance, which is crucial in regions prone to extreme weather conditions.

The Mechanism Behind IBR Roofing Machines

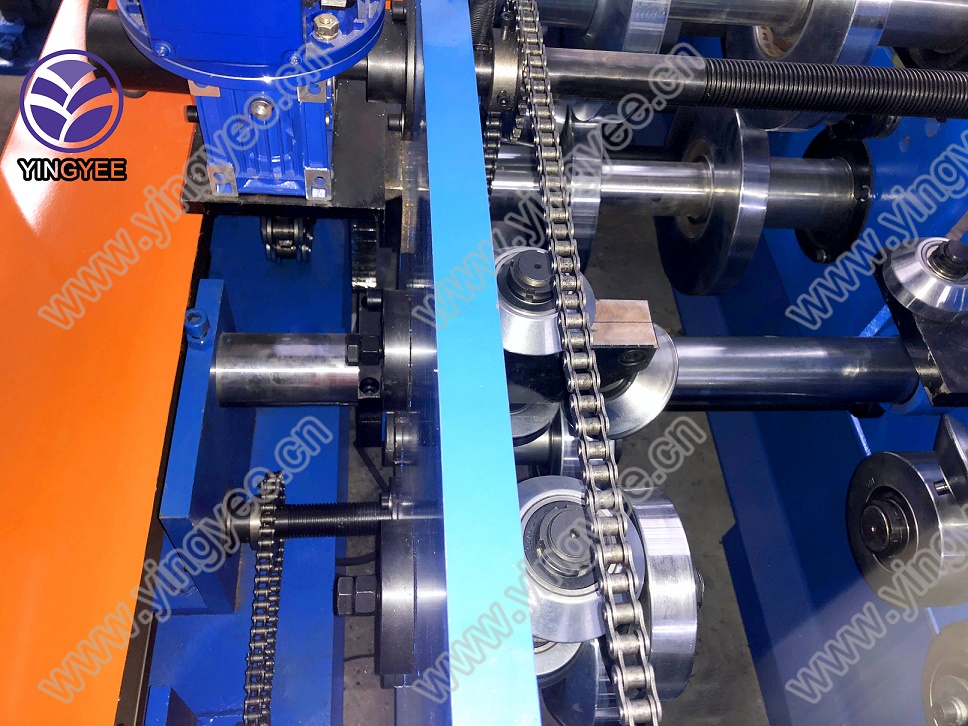

IBR roofing machines are primarily designed to manufacture these specialized roofing sheets with precision. These machines involve advanced technology that allows for the continuous roll-forming of metal sheets into the desired IBR profile. The key components of an IBR roofing machine include

1. Decoiler This component unwinds the raw metal coil, preparing it for the forming process. 2. Roll Forming Station Here, the metal sheet is gradually shaped into the IBR profile through a series of rollers. The process is continuous, ensuring efficiency and consistency. 3. Cutting Mechanism Once the metal sheet has been formed, it is cut to the required length automatically, ensuring minimal waste. 4. Control System Modern IBR roofing machines are equipped with computerized control systems, allowing for precise adjustments and monitoring of the entire production process.

Advantages of Using IBR Roofing Machines

1. Efficiency One of the most significant benefits of IBR roofing machines is their ability to produce large quantities of roofing sheets in a short amount of time. This efficiency helps construction projects stay on schedule and within budget.

2. Customization Manufacturers can easily adjust the machine settings to create different thicknesses, lengths, and colors of roofing sheets. This flexibility caters to varying customer preferences and project requirements.

3. Cost-Effectiveness By reducing labor costs and minimizing material waste, IBR roofing machines contribute to overall cost savings for manufacturers and builders alike. Their durable products also ensure long-term performance, further enhancing value.

4. Quality Assurance Consistent production processes and advanced technology mean that the roofing sheets produced are of high quality, meeting industry standards. This reliability is critical for ensuring the durability and aesthetic appeal of roofs.

Conclusion

The introduction of IBR roofing machines has significantly influenced the construction industry. By enabling the production of high-quality, durable roofing solutions, these machines meet the modern demand for efficiency, customization, and cost-effectiveness. As the construction landscape continues to evolve, the role of IBR roofing machines is likely to expand, paving the way for innovative developments in roofing technologies.

As builders and manufacturers embrace these machines, they contribute to creating structures that not only provide shelter but also enhance the aesthetic value of urban landscapes. With the ongoing advancements in machine technology, the future of IBR roofing solutions looks promising, positioning them as a staple in modern construction practices.