Z-Shape Roll Forming Purlin Machine Enhancing Efficiency in Construction

In the modern construction industry, the quest for durability, efficiency, and cost-effectiveness has led to the adoption of advanced manufacturing technologies. Among these, the Z-shape roll forming purlin machine stands out as a pivotal player in producing high-quality steel purlins. This article delves into the significance of Z-shape purlins, the functionality of roll forming machines, and the benefits they bring to construction projects.

Understanding Z-Shape Purlins

Purlins are horizontal structural members used to support roofing and wall cladding. The Z-shape purlin, characterized by its distinctive cross-section resembling the letter Z, offers several advantages over conventional purlins. It provides greater strength-to-weight ratios, making it an ideal choice for various applications in commercial and industrial buildings. The Z-shape design allows for interlocking connections that enhance structural integrity and simplify the construction process.

The Role of Roll Forming Machines

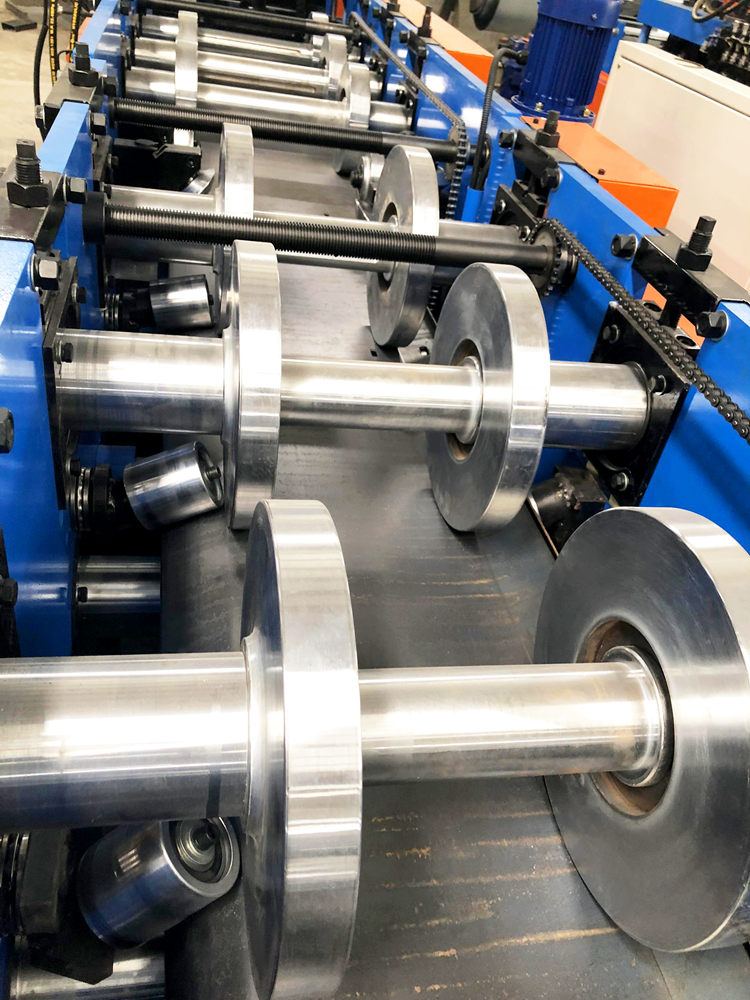

The roll forming process is a continuous bending operation in which a long strip of metal is gradually shaped into a desired cross-section. Z-shape roll forming machines are specifically designed to produce Z-purlins efficiently, ensuring precise dimensions and a consistent finish. The machine operates by feeding a flat metal strip through a series of rollers, each progressively shaping the material until it reaches the final Z-profile.

One of the key advantages of roll forming is its ability to produce long lengths of material with minimal waste. Unlike traditional cutting methods, roll forming can create continuous lengths, significantly reducing scrap and lowering production costs. Additionally, the use of advanced technologies such as computer numerical control (CNC) and automation has enhanced the precision of the roll forming process, ensuring uniformity in every product.

Key Features of Z-Shape Roll Forming Machines

1. High Efficiency Modern Z-shape roll forming machines are designed for speed and efficiency. They can produce large quantities of purlins in a short period, making them ideal for projects with tight timelines.

2. Customizable Options Many manufacturers offer customization options, allowing clients to specify the dimensions, thickness, and mechanical properties of the purlins produced. This flexibility ensures that the purlins meet specific project requirements.

3. Durable Construction These machines are typically built with robust materials that withstand the rigors of continuous operation. Their durability translates to longer operational life and reduced maintenance costs.

4. User-Friendly Controls With advancements in technology, many roll forming machines come equipped with intuitive control systems. This user-friendly interface allows operators to adjust settings easily, minimizing downtime and enhancing productivity.

5. Quality Assurance The precision of the roll forming process ensures high-quality purlins, reducing the likelihood of defects. Many machines are equipped with monitoring systems that ensure consistency and adherence to specifications throughout the production run.

Benefits to the Construction Industry

The use of Z-shape roll forming purlin machines has revolutionized the construction industry in various ways. First and foremost, it enhances productivity by streamlining the manufacturing process, allowing construction projects to progress without delays. Additionally, the lightweight nature of Z-purlins translates to lower shipping costs and simplified handling on-site.

Furthermore, the high strength-to-weight ratio of Z-purlins leads to reduced structural load, allowing for more efficient designs and resource conservation. This sustainability aspect aligns with the growing emphasis on green building practices.

In conclusion, Z-shape roll forming purlin machines have become indispensable tools in modern construction. By offering efficient production, high-quality outputs, and customizable solutions, they play a crucial role in meeting the demands of contemporary building projects. As the construction industry continues to evolve, embracing such technologies will be vital for improving efficiency and sustainability, ultimately paving the way for smarter, more resilient infrastructures.