The Hydraulic Automatic CZ Purlin Touch Screen Forming Machine Revolutionizing Steel Construction

In the ever-evolving world of construction and steel fabrication, the need for efficiency, precision, and adaptability has never been more crucial. One of the pivotal innovations that have emerged in this field is the Hydraulic Automatic CZ Purlin Touch Screen Forming Machine. This sophisticated piece of equipment is revolutionizing the way purlins are produced, offering high precision and state-of-the-art control over the manufacturing process.

Understanding Purlins and Their Importance

Purlins are essential structural components in buildings, particularly in the construction of steel frames. They are horizontal supports that span between beams and are used to support the roof and wall cladding. Traditionally, the manufacture of purlins involved labor-intensive processes that could be both time-consuming and prone to human error. However, with advancements in technology, the production of purlins has seen significant improvements.

The Role of the Hydraulic Automatic Forming Machine

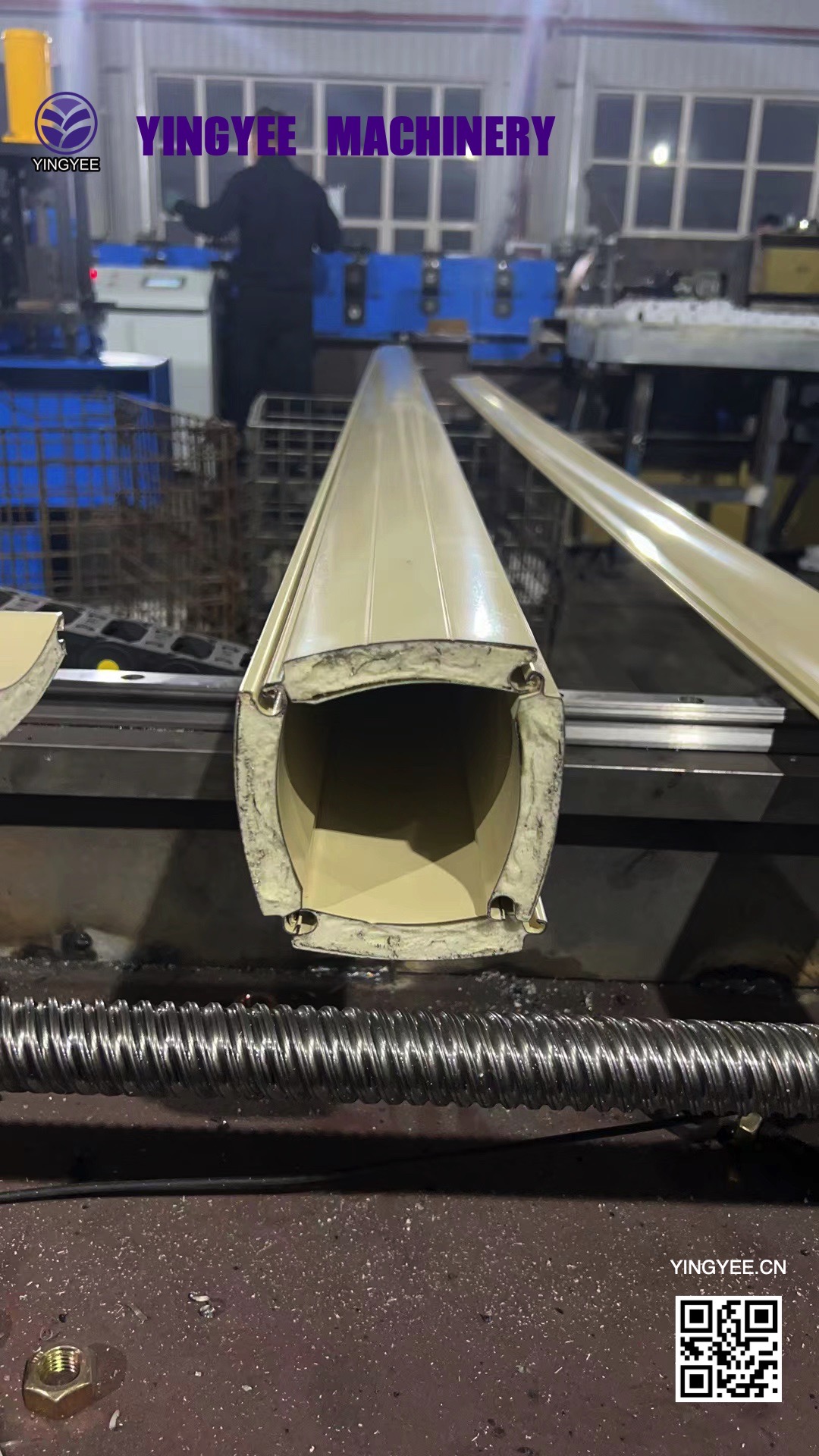

The Hydraulic Automatic CZ Purlin Touch Screen Forming Machine is designed specifically for the rapid production of C and Z-shaped purlins. This machine employs hydraulic technology, which offers several advantages over conventional mechanical systems. Hydraulic systems can exert a significant amount of force with high efficiency, enabling the machine to handle heavier materials and produce a wide range of purlin sizes.

The machine’s touch screen interface is another key feature that sets it apart from traditional purlin forming machines. With a user-friendly control panel, operators can easily input specifications for different purlin profiles, adjust settings, and monitor the manufacturing process in real time. This level of control not only enhances precision but also minimizes the risk of errors, leading to high-quality outputs that meet exact specifications.

Key Features and Benefits

1. High Precision and Consistency The use of hydraulic systems ensures that each purlin is formed with consistent accuracy. This reduces waste and increases overall efficiency, allowing fabricators to meet tight project deadlines without compromising quality.

2. User-Friendly Interface The touch screen interface simplifies the operation of the machine. Operators with minimal training can quickly learn how to use the system, making it easier to integrate into existing workflows.

3. Versatility The machine's ability to produce both C and Z-shaped purlins makes it an invaluable asset for steel fabricators and construction companies. The adjustable settings allow for customization, accommodating various project requirements.

4. Increased Production Speed With automated processes, the forming machine significantly speeds up production times. This is particularly important in the fast-paced construction industry, where time is often a critical factor.

5. Reduced Labor Costs Automation reduces the need for extensive manpower, allowing businesses to allocate resources more effectively. This not only cuts labor costs but also minimizes the risk of injury associated with manual handling.

Conclusion

As the construction industry continues to grow, the demand for efficient and reliable manufacturing solutions will only increase. The Hydraulic Automatic CZ Purlin Touch Screen Forming Machine stands at the forefront of this evolution, offering a blend of advanced technology, precision engineering, and user-friendly operation. With its ability to produce high-quality purlins quickly and efficiently, this machine is set to become an essential tool for builders and fabricators worldwide.

Investing in such technology not only enhances productivity but also contributes to the overall quality of construction projects. As businesses begin to recognize the advantages of automated solutions, the Hydraulic Automatic CZ Purlin Touch Screen Forming Machine is well-positioned to lead the way in modern steel fabrication, proving that innovation is indeed the key to success in the construction industry.