The Role of Storage Rack Upright Shelf Roll Forming Machines

In the ever-evolving world of manufacturing and warehouse management, the efficiency and organization of storage solutions are paramount. One of the most critical components in the design and implementation of storage systems is the storage rack upright shelf roll forming machine. This innovative machinery plays a pivotal role in the production of durable and customizable storage racks, which are essential in various sectors, including retail, manufacturing, and logistics.

Understanding Roll Forming Technology

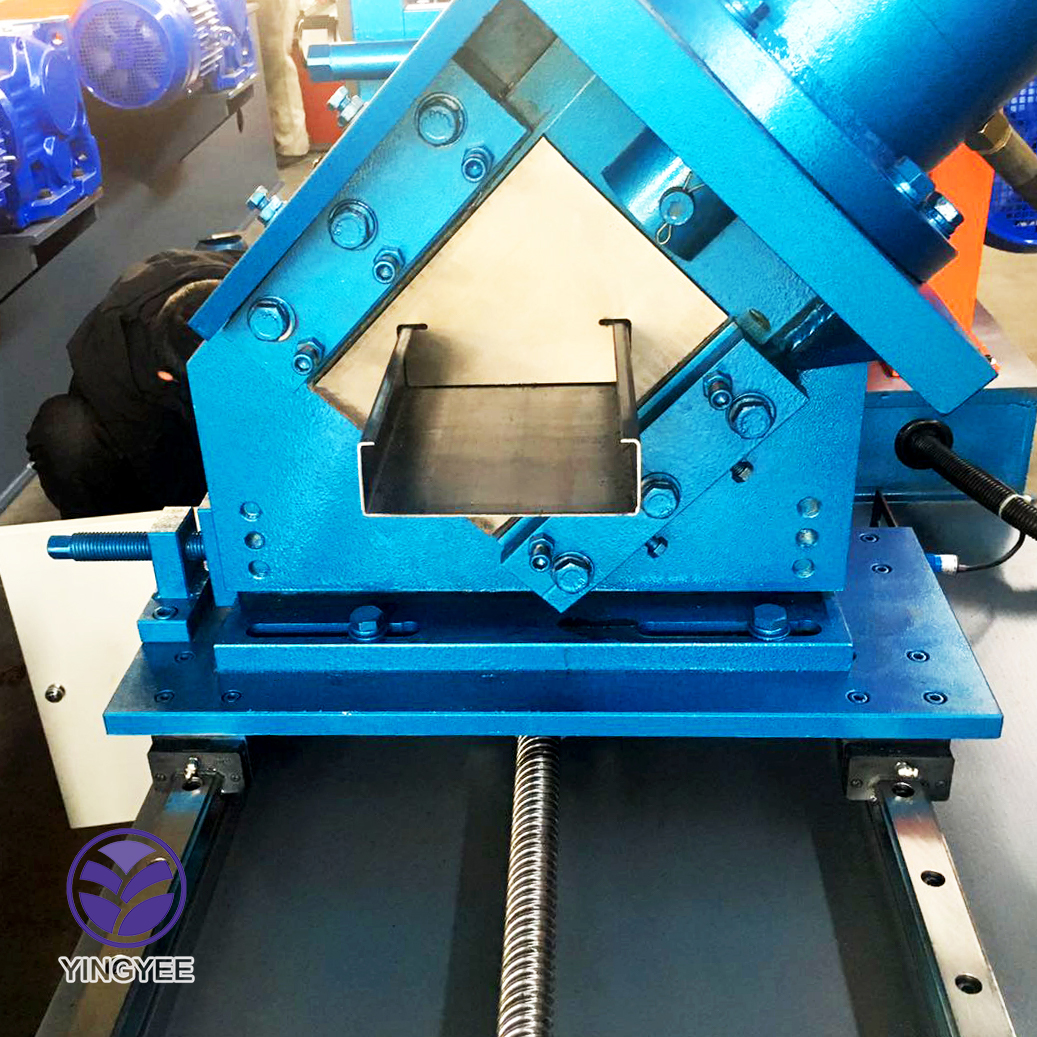

Roll forming is a continuous bending operation where a long strip of sheet metal passes through sets of rolls to achieve the desired cross-section. The process involves feeding metal into the machine, where it is progressively shaped into parts such as uprights and beams that form the backbone of storage racks. This technique is beneficial due to its efficiency; it produces consistent and high-quality components with minimal waste.

Key Features of Storage Rack Upright Shelf Roll Forming Machines

1. High Production Efficiency These machines are designed for mass production, ensuring high output without compromising quality. The automated systems can operate at rapid speeds, significantly reducing lead times for manufacturers.

2. Versatility Storage rack upright shelf roll forming machines are versatile and can be adjusted to produce a variety of rack configurations, accommodating different sizes and load capacities. This adaptability allows manufacturers to cater to diverse customer needs.

3. Customization Options With advancements in technology, modern roll forming machines can be equipped with programmable features that allow for the creation of customized designs based on specific requirements. This flexibility is crucial for businesses that need tailored solutions for their storage needs.

4. Durability and Strength The materials used in the roll forming process, often high-strength steel, ensure that the resulting storage racks are not only durable but also capable of withstanding substantial loads. This reliability is essential in environments where inventory levels can fluctuate significantly.

5. Cost-Effectiveness By optimizing material usage and minimizing waste, roll forming can be a cost-effective manufacturing solution. Additionally, the longevity and strength of the racks reduce the need for frequent replacements, providing a better return on investment for companies.

Applications in Various Industries

The storage rack upright shelf roll forming machine finds applications across several industries

- Warehousing and Distribution Centers Efficient storage solutions are critical in warehouses where space management is essential. Roll-formed racks optimize vertical space, allowing for more inventory to be stored efficiently.

- Retail Outlets Retail businesses use these racks for displaying products in a way that maximizes customer accessibility while ensuring safety and organization.

- Manufacturing Plants In manufacturing environments, storage racks help in organizing tools, components, and finished goods, contributing to streamlined operations and enhanced productivity.

Conclusion

The storage rack upright shelf roll forming machine represents a significant advancement in the manufacturing of storage solutions. As businesses continue to seek efficient, durable, and customizable storage systems, the demand for such machinery will only grow. By integrating these machines into production lines, manufacturers can not only enhance their operational efficiency but also provide their customers with superior storage options that meet modern demands. In an era where space optimization and efficiency speak volumes about a company’s success, the pivotal role of roll forming technology in producing robust storage racks cannot be overstated. As we look to the future, continuous innovation in this field will shape the way industries approach storage and organization.