The Evolution of Hydraulic Automatic CZ Purlin Touch Screen Forming Machines

In recent years, the construction industry has undergone significant transformations driven by technological advancements. One of the standout innovations is the hydraulic automatic CZ purlin touch screen forming machine. This state-of-the-art equipment not only enhances efficiency in producing purlins but also revolutionizes the way construction materials are fabricated, providing manufacturers with a competitive edge.

What is a CZ Purlin?

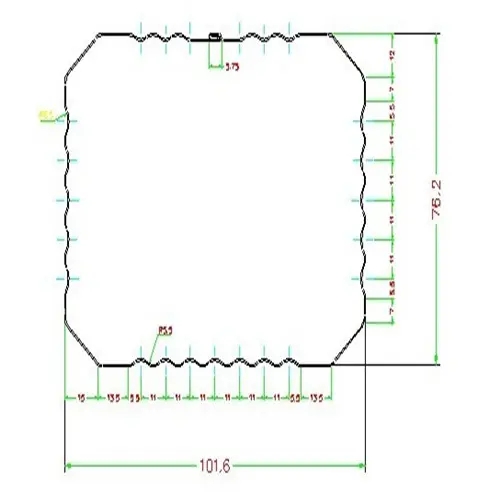

CZ purlins are structural beams made from cold-formed steel that serve as essential components in steel buildings. They are primarily used for supporting roofs and walls, providing vital structural support and stability. The design and versatility of CZ purlins make them incredibly popular in various construction applications ranging from commercial buildings to agricultural structures.

The Role of Hydraulic Automatic Machines

The hydraulic automatic CZ purlin forming machine automates the entire process of shaping, cutting, and finishing the purlins. Traditional manufacturing methods often involve labor-intensive processes that can be time-consuming and prone to errors. In contrast, hydraulic machines provide precision, consistency, and speed, drastically improving production rates while minimizing waste and resource use.

Key Features

One of the most remarkable features of these machines is the touch screen interface. The incorporation of touchscreen technology allows users to easily program and monitor the machine's operations. Operators can adjust settings such as purlin size, thickness, and production speed with just a few taps on the screen. This user-friendly design reduces the likelihood of errors during setup and operation, leading to higher-quality outputs.

Moreover, the hydraulic system employed in these machines delivers significant force, enabling the production of high-strength purlins that can withstand considerable loads. This hydraulic functionality not only improves the quality of the resulting purlins but also enhances the machine's longevity and reliability.

Efficiency and Productivity

The introduction of hydraulic automatic CZ purlin forming machines has markedly increased productivity in manufacturing processes. With the ability to continuously produce purlins without the need for frequent stops or interventions, manufacturers can meet higher demand levels and tighter deadlines. This is particularly crucial in today’s fast-paced construction environment, where timely project completion is essential for maintaining client satisfaction and competitive advantages.

Additionally, these machines often come equipped with automatic cutting and stacking features, further streamlining the production line. Once the purlin is formed, it can be cut to size and stacked automatically, reducing the need for manual handling and minimizing the risk of injury.

Cost-effectiveness and Sustainability

Investing in hydraulic automatic CZ purlin forming machines is not only a step towards modernization but also a cost-effective decision. Although the initial investment may be significant, the long-term savings in labor costs, material waste, and production time can be substantial. Furthermore, as industries move towards more sustainable practices, the efficiency of these machines contributes to reduced energy consumption and waste outputs, aligning with contemporary environmental standards.

Conclusion

The hydraulic automatic CZ purlin touch screen forming machine represents a pinnacle of engineering innovation in the construction industry. By marrying advanced technology with practical design, these machines are transforming the way purlins are produced. As the demand for efficient and reliable construction materials grows, the integration of such advanced machinery will surely play a crucial role in shaping the future of construction, ensuring that manufacturers can deliver high-quality products faster and more sustainably than ever before. The future of construction is here, and it’s automated, efficient, and user-friendly.