The Evolution and Importance of Composite Floor Deck Cold Bending Machines

In the realm of construction and structural engineering, the efficiency and effectiveness of building materials and techniques are paramount. One particular innovation that has gained significant attention is the composite floor deck cold bending machine. This equipment has revolutionized the way composite floor decks are designed, manufactured, and installed, providing a myriad of benefits that streamline the construction process and enhance structural integrity.

Understanding Composite Floor Decks

Composite floor decks are a type of flooring system that combines steel and concrete to create a robust and lightweight solution for modern buildings. These decks are typically composed of a metal deck that is installed over steel beams, followed by the pouring of concrete, which then adheres to the deck to form a singular unit. The combination of materials allows for high strength-to-weight ratios, enabling expansive open spaces while minimizing the use of excess materials. The cold bending process plays a crucial role in accommodating various architectural designs and structural requirements.

The Function of Cold Bending Machines

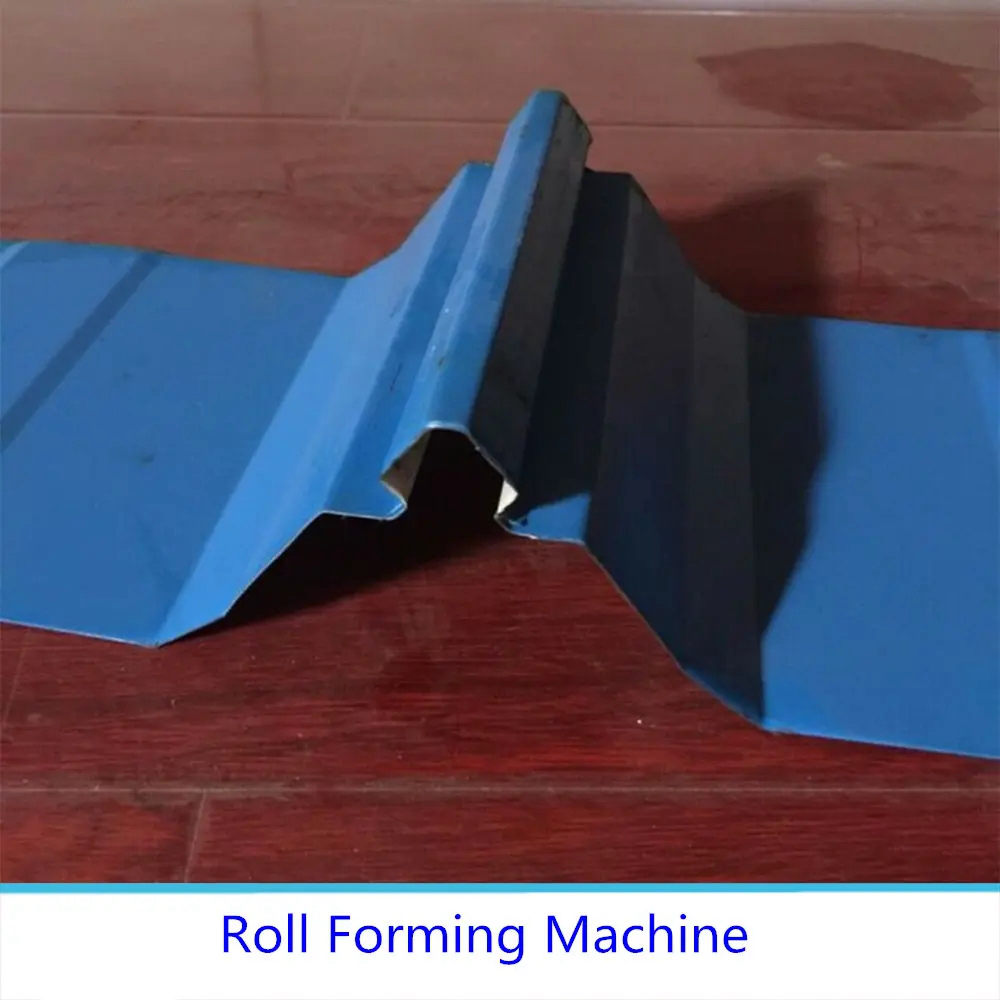

Cold bending machines are designed to manipulate metal without the application of heat, preserving the material's integrity while allowing for significant structural adjustments. For composite floor decks, these machines are instrumental in creating custom shapes and forms that meet specific design needs. The precision offered by cold bending machines minimizes waste and optimizes the use of materials, contributing to overall cost savings in construction projects.

The bending process itself involves feeding steel sheets into the machine, which then applies mechanical force to bend the material to the desired angle or contour. This process can be adjusted to accommodate various thicknesses and types of metal, making it a versatile tool in the construction industry.

Advantages of Using Cold Bending Machines

1. Efficiency and Speed Traditional methods of bending and shaping metal can be time-consuming and labor-intensive. Cold bending machines significantly reduce the time required to produce composite floor decks by automating the bending process and allowing for continuous production.

2. Cost-Effectiveness By minimizing material waste and reducing labor costs, cold bending machines provide a more cost-effective solution compared to manual bending techniques. This translates to lower overall project costs for construction companies.

3. Precision Engineering The accuracy of cold bending machines ensures that every piece of metal is shaped to exact specifications. This precise engineering is crucial for maintaining structural integrity and alignment during installation.

4. Versatility These machines can work with a variety of metal types and thicknesses, allowing for greater flexibility in design. Whether constructing a commercial high-rise or a residential building, cold bending machines can accommodate diverse project requirements.

5. Safety The automation of bending processes reduces the risk of injury that can occur with manual handling of metal. Furthermore, cold bending eliminates the hazardous conditions associated with heating metal, making the workplace safer for construction crews.

Conclusion

The composite floor deck cold bending machine is a testament to the advancements in construction technology, reflecting the industry's ongoing pursuit of efficiency, cost-effectiveness, and safety. As the demand for innovative building solutions continues to grow, these machines will play an increasingly vital role in shaping the future of construction. Their ability to produce high-quality, customized composite floor decks will not only enhance the structural integrity of buildings but also support architects and engineers in their creative endeavors, paving the way for more complex and ambitious designs. In an industry that must continuously adapt to new challenges, the implementation of cold bending technology is a significant step forward.