Highway Fence Guardrail Roll Forming Machine A Comprehensive Overview

Highway safety is a paramount concern for governments and transportation authorities worldwide. One of the critical components in ensuring the safety of vehicles on highways is the use of guardrails. To manufacture these essential safety features, the highway fence guardrail roll forming machine plays a pivotal role. This article delves into the importance, functionality, and benefits of this advanced manufacturing equipment.

Understanding Guardrails and Their Importance

Guardrails, often seen alongside highways, are designed to prevent vehicles from veering off the road. They protect drivers, passengers, and pedestrians from potential hazards such as steep embankments, roadside obstacles, and oncoming traffic. The primary function of guardrails is to absorb the impact of a collision and redirect vehicles back onto the road. Given their crucial role in highway safety, the manufacturing of guardrails must be precise and efficient.

What is a Highway Fence Guardrail Roll Forming Machine?

A highway fence guardrail roll forming machine is a specialized piece of equipment used to produce guardrails in a continuous manner. The machine utilizes a series of rollers and dies to transform flat metal sheets into the desired guardrail shapes and profiles. This process is known as roll forming, which is an efficient method for producing long lengths of uniform cross-sections, making it ideal for manufacturing guardrails.

The Roll Forming Process

The roll forming process involves several key steps

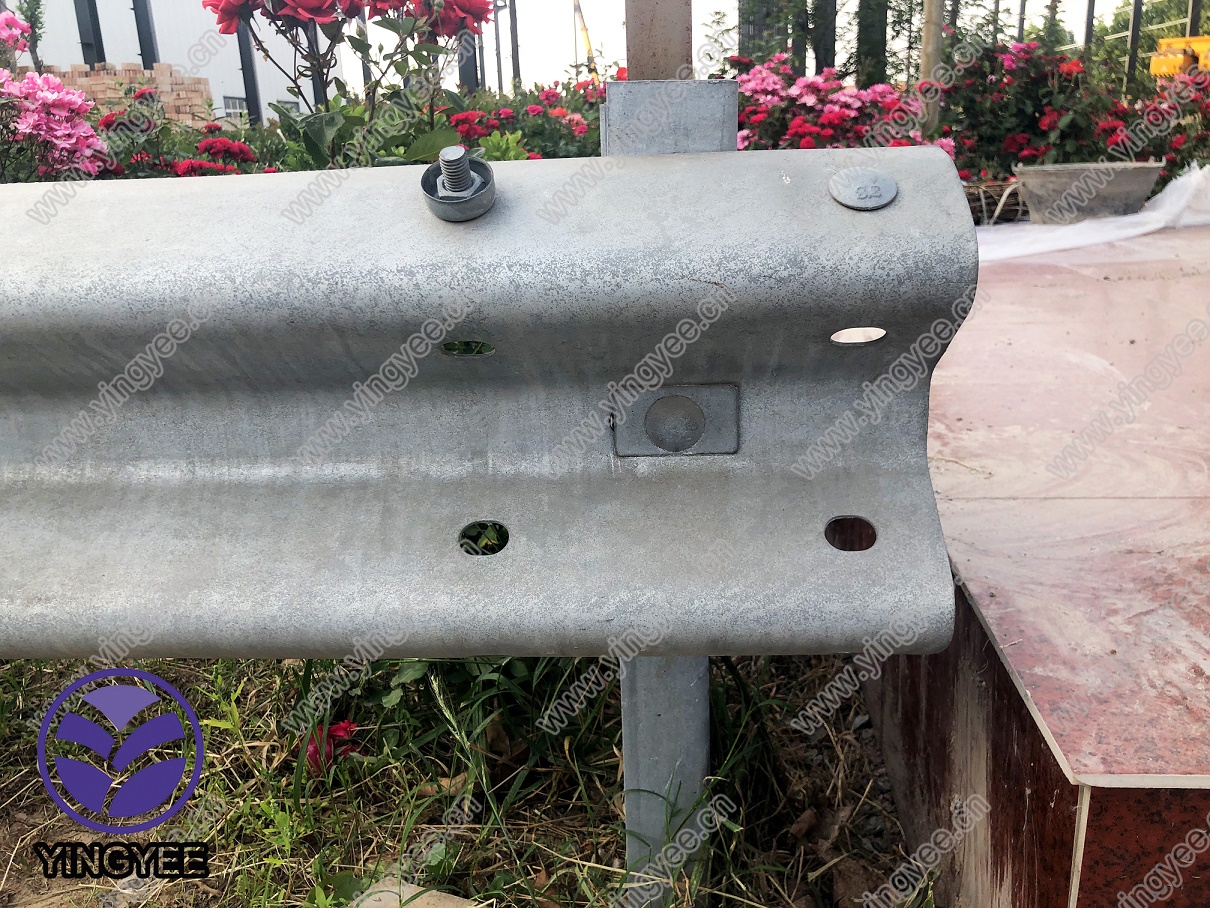

1. Material Preparation The process begins with high-quality raw materials, typically galvanized steel, to ensure durability and resistance to corrosion.

2. Roll Forming Setup The prepared metal sheets are fed into the roll forming machine. Multiple rollers are arranged in a sequence that gradually bends and shapes the metal into the desired profile.

3. Cutting and Finishing Once the metal has been formed into guardrail sections, it is cut to specific lengths. Additional processes, such as punching holes for installation and surface treatment, may be applied to enhance performance and aesthetics.

4. Quality Control To ensure that the produced guardrails meet safety standards, rigorous quality control measures are implemented throughout the manufacturing process. This includes checking the dimensions, strength, and finish of each guardrail section.

Advantages of Using Roll Forming Machines

The use of highway fence guardrail roll forming machines offers several significant advantages

1. Efficiency The roll forming process is highly efficient, producing long lengths of guardrails in a continuous manner. This minimizes production time and maximizes output.

2. Cost-Effectiveness By reducing material waste and labor costs, roll forming machines provide a cost-effective solution for manufacturers. The efficiency of the process translates into lower manufacturing costs, which can benefit the final consumer.

3. Customizability Roll forming machines can be customized to produce various guardrail profiles, allowing manufacturers to meet specific requirements of different highway projects.

4. Durability The use of high-quality materials, combined with the precision of the roll forming process, results in the production of guardrails that are robust and long-lasting, providing reliable protection on highways.

5. Automation and Control Modern roll forming machines often incorporate advanced automation technology, allowing for precise control over the manufacturing process. This leads to uniform quality and reduces the dependency on manual labor.

Conclusion

In conclusion, the highway fence guardrail roll forming machine is an integral part of modern highway safety infrastructure. Its ability to efficiently produce high-quality guardrails ensures that roads remain safe for all users. As technology continues to advance, we can expect further improvements in the efficiency and effectiveness of these machines, enhancing the production of guardrails and contributing to safer driving experiences globally. The investment in roll forming technology not only improves manufacturing processes but also significantly contributes to public safety on highways.