The Evolution and Importance of Roofing Sheet Forming Galvanized Steel Machines

In the modern age of construction, the roofing industry plays a crucial role in ensuring the safety, durability, and aesthetic appeal of buildings. One of the pivotal components in this industry is the roofing sheet, particularly those made from galvanized steel. The process of forming these sheets has been significantly enhanced by the advent of specialized machines designed to streamline production.

Understanding Galvanized Steel

Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion. This protective layer makes galvanized steel extremely popular in various applications, especially in roofing, where exposure to the elements can be particularly harsh. The combination of steel's strength and zinc's corrosion resistance results in roofing sheets that are not only durable but also lightweight and cost-effective.

The Role of Roofing Sheet Forming Machines

Roofing sheet forming machines are specifically designed equipment that manufactures roofing sheets from pre-galvanized steel coils. These machines employ a series of rollers to shape the flat steel sheets into various profiles and thicknesses. The process typically involves several stages

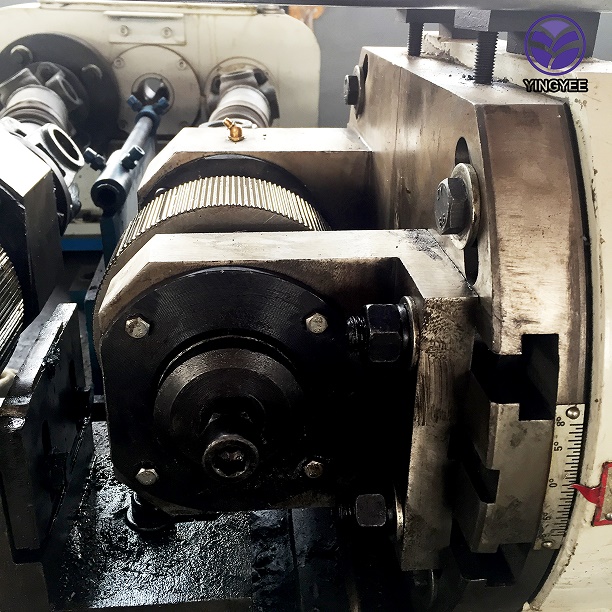

1. Material Feeding The galvanised steel coil is fed into the machine, where it is unwound and positioned for shaping. 2. Roll Forming The metal passes through several roller stations. Each station incrementally bends the metal until it reaches the desired profile—be it a corrugated shape, a flat sheet, or a ribbed surface.

3. Cutting Once the desired length has been reached, a cutting mechanism trims the sheet to the specified size.

Advantages of Using Roofing Sheet Forming Machines

The use of specialized roofing sheet forming machines offers several advantages

- Efficiency These machines are designed for high-speed production, allowing manufacturers to produce a large volume of sheets in a short amount of time, thereby meeting market demands quickly.

- Precision Automated forming processes ensure that the sheets are manufactured with high accuracy, reducing waste and minimizing the chance of defects.

- Versatility Roofing sheet forming machines can be adjusted to create various profiles and thicknesses, enabling manufacturers to cater to different customer requirements and preferences.

- Durability The resulting galvanized steel roofing sheets boast impressive longevity, often lasting for decades without significant maintenance, thanks to the corrosion-resistant properties of zinc.

The Importance of Innovation

As technology progresses, roofing sheet forming machines continue to evolve. Innovations such as computer numerical control (CNC) have led to heightened precision and customization capabilities. Furthermore, advancements in materials technology mean that modern galvanized steel can be produced with even better corrosion resistance and strength, providing consumers with higher quality products.

Conclusion

In conclusion, roofing sheet forming galvanized steel machines are essential to the construction and roofing industries. They not only enhance production efficiency and quality but also contribute to the overall safety and longevity of buildings. As demand for durable, cost-effective, and fast-produced solutions continues to grow, these machines will remain at the forefront of roofing technology, ensuring that structures are both resilient and aesthetically pleasing for years to come. As we look to the future, ongoing innovations in this sector promise to further revolutionize roofing solutions, making them more accessible and sustainable for everyone.