Gutter Elbow Machine for Sale A Comprehensive Guide

In the world of manufacturing, efficiency and precision are paramount. Among the essential tools needed for creating high-quality gutter systems, the gutter elbow machine stands out. This machine is specifically designed to produce various types of gutter elbows, which are integral components for directing rainwater away from a roofline or building. As a result, the demand for gutter elbow machines is on the rise, making them a valuable addition to any metalworking shop or manufacturing facility.

Understanding Gutter Elbow Machines

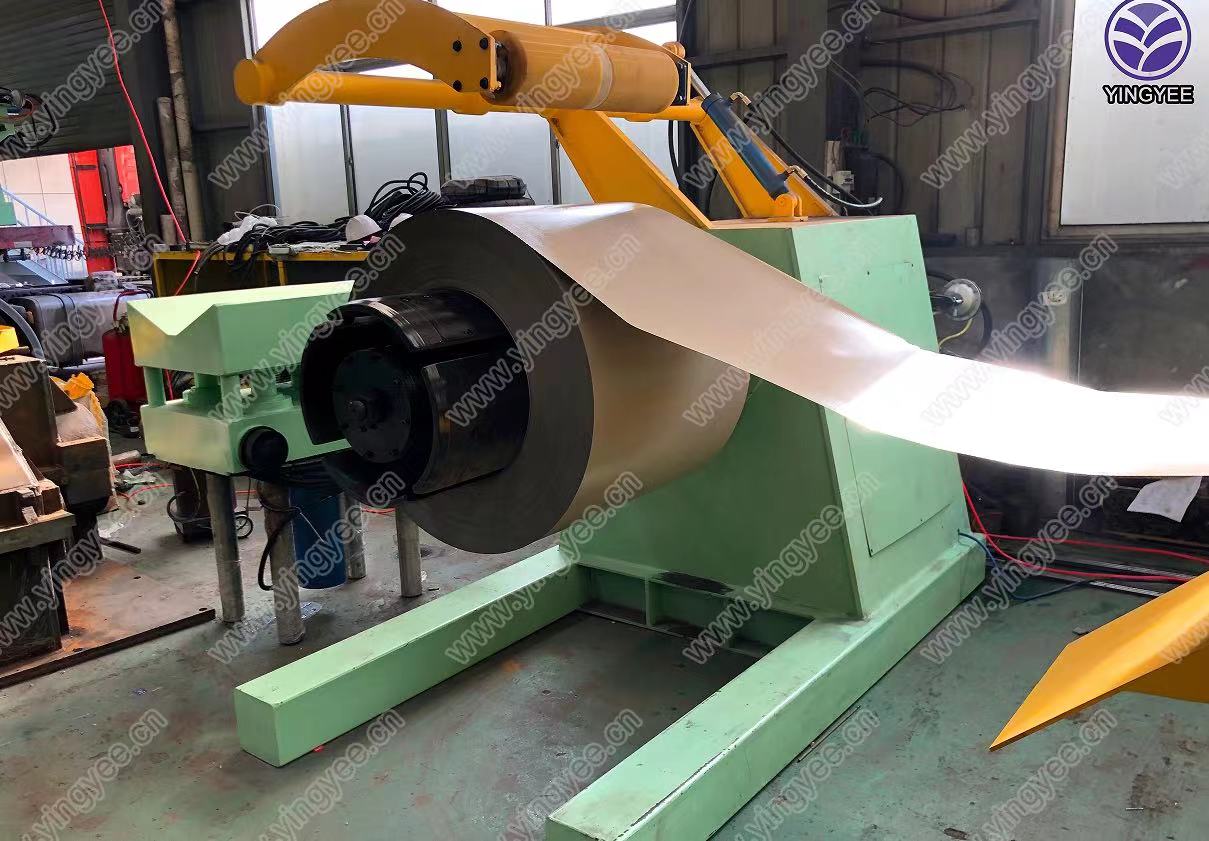

Gutter elbow machines are specialized machinery used to bend and shape metal into elbow configurations that fit seamlessly into gutter systems. These machines can effectively handle different widths and materials, including aluminum, steel, and copper, catering to diverse industry needs. Typically, a gutter elbow machine employs advanced technology such as CNC (Computer Numerical Control) for precision bending, ensuring that each product meets exact specifications.

The primary functions of a gutter elbow machine include cutting, bending, and forming materials into specific angles, usually ranging between 30 to 90 degrees. The ability to produce precise angles is crucial in preventing potential water pooling, which can lead to structural damages over time.

Benefits of Investing in a Gutter Elbow Machine

1. Increased Efficiency Gutter elbow machines are designed to streamline manufacturing processes. With automated features, these machines can produce large quantities of gutter elbows in a fraction of the time it would take to do so manually. This enhances productivity, particularly for businesses that cater to high-volume orders.

2. Cost Savings By investing in a gutter elbow machine, companies can significantly reduce labor costs associated with manual production methods. The initial investment may seem substantial, but the long-term savings and increased output frequently justify the expense.

3. Quality Control Automated machines maintain high levels of accuracy and consistency, which is vital for ensuring that all products meet rigorous industry standards. This quality assurance helps businesses maintain their reputation and reduces waste caused by defective products.

4. Versatility Many modern gutter elbow machines can accommodate various sizes and materials, allowing manufacturers to diversify their product offerings. This versatility can open new markets and attract a wider customer base, contributing to business growth.

Where to Find Gutter Elbow Machines for Sale

When looking for gutter elbow machines for sale, it is essential to research reputable manufacturers and suppliers. Many companies offer a range of options, including new and refurbished machines, catering to different budget levels. Online marketplaces, industrial equipment suppliers, and trade exhibitions often feature a wide selection of machines.

Before making a purchase, consider the following factors

- Specifications Ensure the machine can handle the types of materials and sizes you plan to work with. - Warranty and Support Look for machines that come with a warranty and reliable customer support services. This will protect your investment and provide peace of mind. - Reviews and Reputation Research customer reviews and ratings to gauge the reliability and performance of the machines you are considering.

Conclusion

A gutter elbow machine is a valuable asset for any business involved in gutter manufacturing. With its ability to enhance efficiency, reduce costs, and maintain high-quality production standards, investing in this machinery can provide a significant competitive edge in the marketplace. As demand continues to grow, businesses should seize the opportunity to integrate advanced gutter elbow machines into their operations, paving the way for success in the ever-evolving construction and metalworking industries.