The Advancements of China's Automatic Cut-to-Length Lines

In the realm of manufacturing and processing, precision is paramount. One of the most significant advancements in this field is the development of automatic cut-to-length lines. In recent years, China has emerged as a leader in this technology, providing innovative solutions for various industries, including steel, aluminum, and other metals. The automatic cut-to-length line is designed to streamline the cutting process, ensuring efficiency, accuracy, and quality.

Understanding Automatic Cut-to-Length Lines

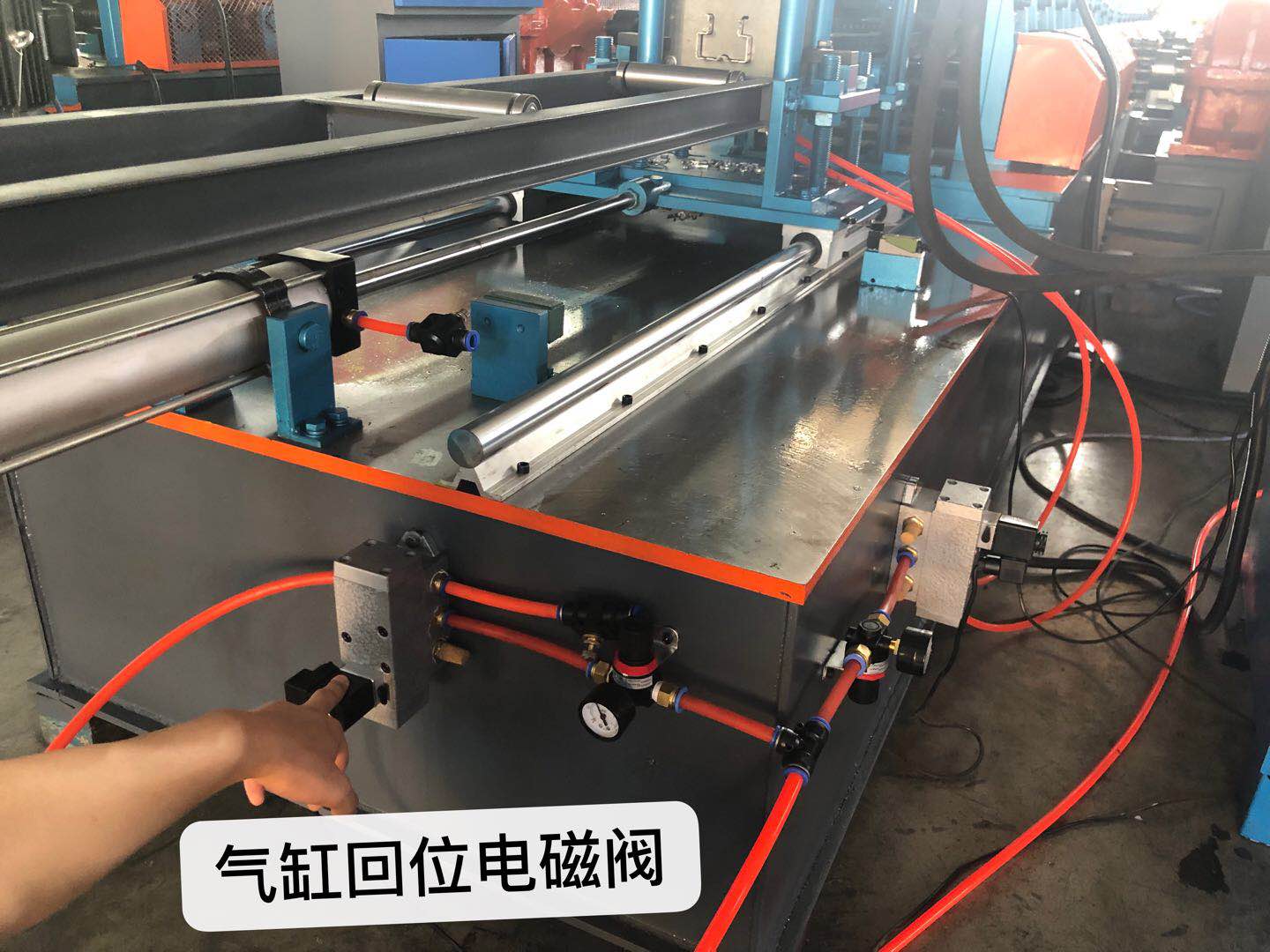

An automatic cut-to-length line is a system that processes long coils or sheets of material and cuts them into predetermined lengths as per the specific needs of the customer. This technology is crucial for companies dealing with materials that require exact dimensions, such as in the automotive, construction, and appliance industries. These lines typically consist of several key components, including uncoilers, levelers, shears, and conveyors, all working together to create a seamless production process.

Key Features and Benefits

The primary advantages of automatic cut-to-length lines include enhanced efficiency and reduced labor costs. Traditionally, cutting operations required significant manual labor and were prone to human error. With the introduction of automation, these lines can operate with minimal human intervention, leading to faster processing times and reduced operational costs.

Moreover, the precision of cut-to-length lines ensures a high level of product quality. Automatic systems are equipped with advanced technology that allows them to accurately measure and cut materials, minimizing waste and ensuring that each piece meets the specified dimensions. This precision is vital, particularly in industries where even the slightest deviation can result in production delays or increased costs.

Technological Innovations

China's investment in research and development has led to significant technological advancements in the design and functionality of cut-to-length lines. Modern systems often incorporate features such as real-time monitoring and control, which enable operators to oversee the entire process from a centralized interface. This capability allows for immediate adjustments to be made, ensuring that production remains on track and that any issues are promptly addressed.

Additionally, many of these lines are designed with flexibility in mind. They can accommodate a variety of materials and thicknesses, making them suitable for diverse applications. This adaptability is particularly beneficial for manufacturers that need to respond quickly to changing customer demands or market conditions.

The Role of Sustainability

As industries worldwide move towards more sustainable practices, China's automatic cut-to-length lines also reflect this trend. Advanced technologies help to minimize material waste through precise cutting and efficient processing. Furthermore, manufacturers are increasingly utilizing recycled materials, which these lines can easily accommodate, making them a valuable asset in the quest for sustainability.

Conclusion

The evolution of automatic cut-to-length lines in China signifies a major leap forward in manufacturing technology. By enhancing efficiency, precision, and sustainability, these systems are transforming how industries approach their production processes. As China continues to innovate and invest in automation, it is likely that these advancements will spread globally, setting new standards for the manufacturing sector. The future of manufacturing is undoubtedly intertwined with the capabilities offered by automatic cut-to-length lines, paving the way for smarter, more efficient production methods.