The Czu Steel Purlin Roll Forming Machine Revolutionizing Construction Industry

In recent years, the construction industry has been experiencing significant advancements in technology, with the introduction of innovative machinery that enhances efficiency, productivity, and quality. One such groundbreaking innovation is the Czu Steel Purlin Roll Forming Machine. This state-of-the-art equipment is designed to produce high-quality steel purlins used in various construction applications, including industrial buildings, warehouses, and commercial structures.

What is a Steel Purlin?

Steel purlins are critical components in the construction sector, acting as secondary structural members that support the roof and wall cladding. They are typically C or Z-shaped and come in various sizes and thicknesses to accommodate different architectural requirements. By providing structural support and stability, purlins play an essential role in ensuring the longevity and safety of a building.

The Czu Steel Purlin Roll Forming Machine

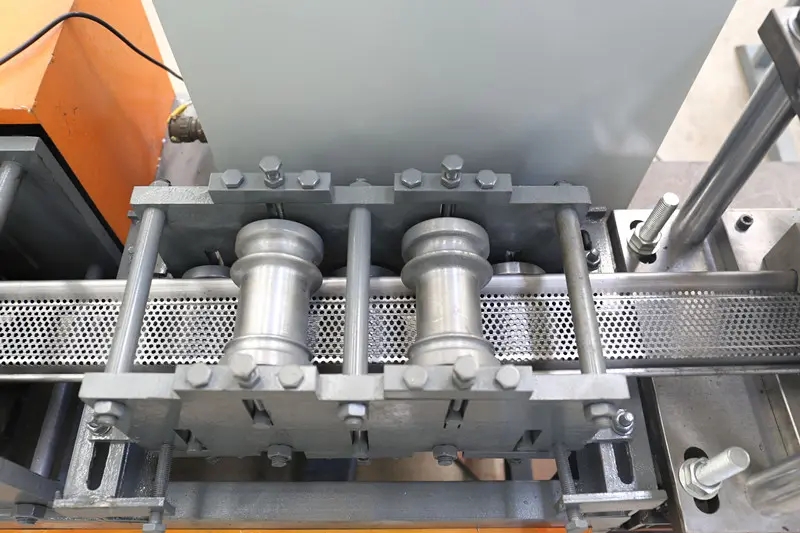

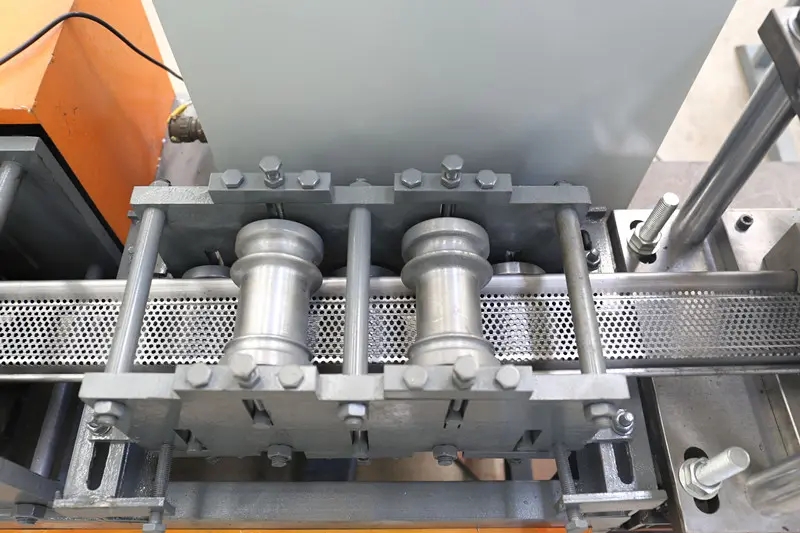

The Czu Steel Purlin Roll Forming Machine is engineered to produce steel purlins in a continuous, efficient manner. The roll forming process involves feeding a flat steel strip through a series of rollers, progressively shaping it into the desired cross-sectional profile. This automated process significantly reduces manual labor and enhances production speed, allowing construction companies to meet tight deadlines without compromising on quality.

One of the key features of the Czu machine is its versatility. It is capable of producing different types of purlins, including C-purlins, Z-purlins, and even custom profiles tailored to specific project requirements. This adaptability makes it an invaluable asset for manufacturers and builders looking to diversify their product offerings and cater to a broader range of construction needs.

Advantages of Using Czu Steel Purlin Roll Forming Machine

czu steel purlin roll froming machine

1. Cost Efficiency The automated process of roll forming minimizes waste and optimizes raw material usage. With the ability to produce purlins on-demand, companies can reduce inventory costs and better manage their resources.

2. High Precision and Quality The Czu machine employs advanced technology that ensures precise dimensions and consistent quality of purlins. This high level of accuracy reduces the need for additional processing, thus saving time and resources.

3. Durability and Strength Steel purlins produced by the Czu machine are known for their superior strength and durability. This resilience is crucial for maintaining structural integrity in various environmental conditions.

4. Ease of Operation The Czu Steel Purlin Roll Forming Machine is user-friendly, requiring minimal operator training. Its intuitive control panel allows users to adjust settings quickly and efficiently, streamlining the production process.

5. Environmental Considerations The modern design of the Czu machine incorporates energy-efficient components and processes, which contribute to a lower environmental impact. By optimizing material usage and reducing waste, this machine aligns with sustainable construction practices.

Conclusion

The introduction of the Czu Steel Purlin Roll Forming Machine is a game-changer for the construction industry. By providing a reliable, efficient, and versatile solution for purlin production, it enables companies to keep up with the growing demands of modern construction. As the building industry continues to evolve, innovations like the Czu machine will play an essential role in shaping a more efficient and sustainable future. Investing in such technology not only enhances productivity but also ensures that construction firms remain competitive in a rapidly changing market. Embracing these advancements is key to driving growth and success in the ever-evolving landscape of construction.