Understanding the C-Shaped Steel Roll Forming Machine

In the construction and manufacturing industries, efficiency and precision are critical factors for success. One of the remarkable advancements in these sectors is the C-shaped steel roll forming machine, a specialized equipment designed to produce C-shaped steel sections used in various applications. This article explores the functionality, advantages, and applications of C-shaped steel roll forming machines.

What is a C-Shaped Steel Roll Forming Machine?

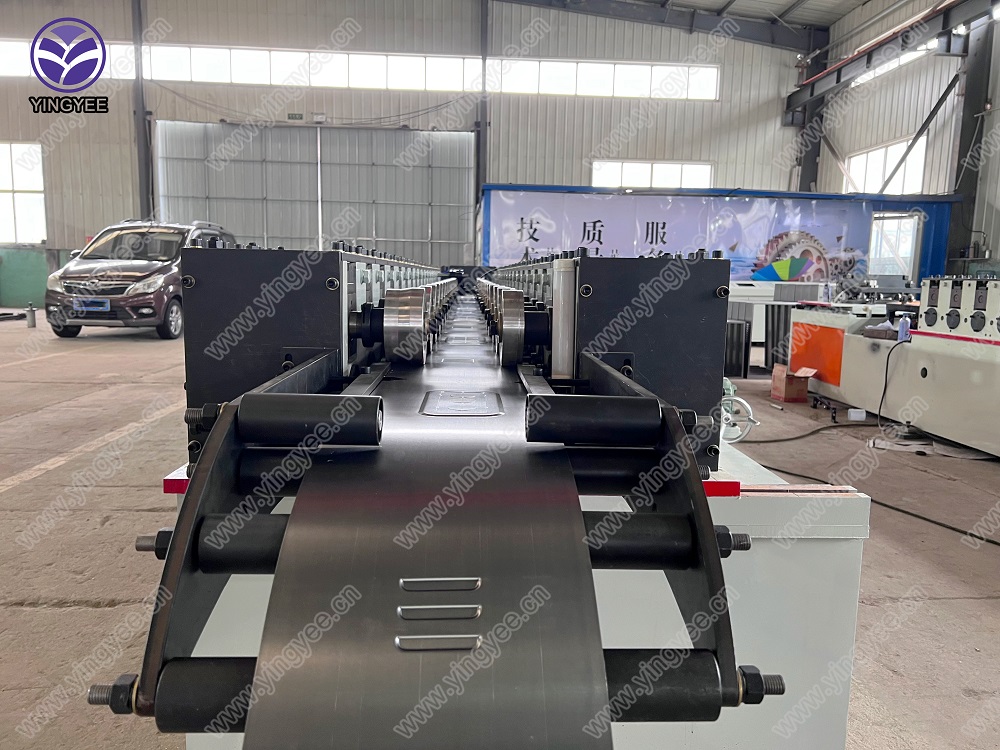

A C-shaped steel roll forming machine is a piece of machinery specifically engineered to produce C-section steel by utilizing a series of rollers. The machine takes flat steel sheets and forms them into a C-shape through a continuous process of bending and shaping. This method ensures that the finished product maintains uniformity, strength, and dimensional accuracy.

How Does It Work?

The operation of a C-shaped steel roll forming machine involves several stages. First, flat steel sheets are fed into the machine. As the sheets pass through various rollers, they are gradually bent and shaped into the desired C-section profile. The precise control of roller alignment and pressure is crucial to ensure that the final product adheres to exact specifications. Once formed, the C-shaped steel can be cut to length, providing manufacturers with a ready-to-use component for assembly.

Advantages of Using C-Shaped Steel Roll Forming Machines

1. Efficiency These machines are capable of producing large quantities of C-shaped steel sections in a short time frame. The continuous forming process minimizes downtime, enhancing productivity.

2. Precision High-quality rollers designed for accurate shaping ensure that the dimensions of the C-section are consistent and precise. This precision reduces waste and the need for rework, ultimately saving time and resources.

3. Customization Many C-shaped steel roll forming machines can be customized to produce specific dimensions and designs, making them versatile for various projects. This adaptability allows manufacturers to meet unique client requirements.

4. Economic Though the initial investment in a roll forming machine may be considerable, the long-term savings gained from reduced labor costs and material waste often justify the cost.

5. Durability C-shaped steel sections produced by these machines exhibit high strength-to-weight ratios, making them ideal for supporting structures without being excessively heavy.

Applications of C-Shaped Steel

C-shaped steel sections are widely used across several industries. In construction, they serve as essential components in steel frames, providing structural support for buildings, bridges, and other infrastructure. They are commonly utilized in manufacturing warehouses or industrial buildings where durability and strength are paramount. Additionally, C-shaped steel profiles are used in the production of various machinery and equipment, demonstrating their versatility in different applications.

Conclusion

The C-shaped steel roll forming machine is a pivotal tool in modern manufacturing and construction. Its ability to produce high-quality, precise C-shaped steel sections efficiently makes it an invaluable asset. As industries continue to evolve, the demand for specialized machinery like the C-shaped steel roll forming machine is likely to grow, driving innovation and efficiency in structural engineering and beyond. Whether you are in construction, manufacturing, or another field that utilizes steel components, understanding the benefits and functional dynamics of these machines can provide a competitive edge in today’s marketplace.