Right Channel Roll Forming Machine with High Straightness

In the world of manufacturing and metal processing, the right channel roll forming machine has emerged as an essential tool for producing high-quality, precise metal components. This sophisticated machinery is particularly known for its ability to deliver high straightness in the final products, making it a favorite in industries such as construction, automotive, and appliance manufacturing. This article delves into the significance of high straightness in channel formation and the advanced technology behind modern roll forming machines.

Understanding Roll Forming

Roll forming is a metal forming process that involves feeding a continuous strip of metal through a series of rollers. These rollers progressively shape the metal into desired cross-section profiles. This method is known for its efficiency, as it facilitates high production rates and uniformity in the final product. One of the key advantages of roll forming is its ability to produce longer lengths of material without joints, which is particularly beneficial in numerous applications.

Importance of High Straightness

High straightness is crucial when it comes to channel profiles in various applications. Metal channels are often used as structural supports or as framing components in construction. Any deviations or bends in the metal can lead to structural weaknesses and complications during installation. A channel with high straightness ensures that the components fit together seamlessly, promoting stability and durability in the overall construction. Furthermore, precision in metal profiles allows for easier integration with other materials and parts, enhancing overall project efficiency.

Features of Right Channel Roll Forming Machines

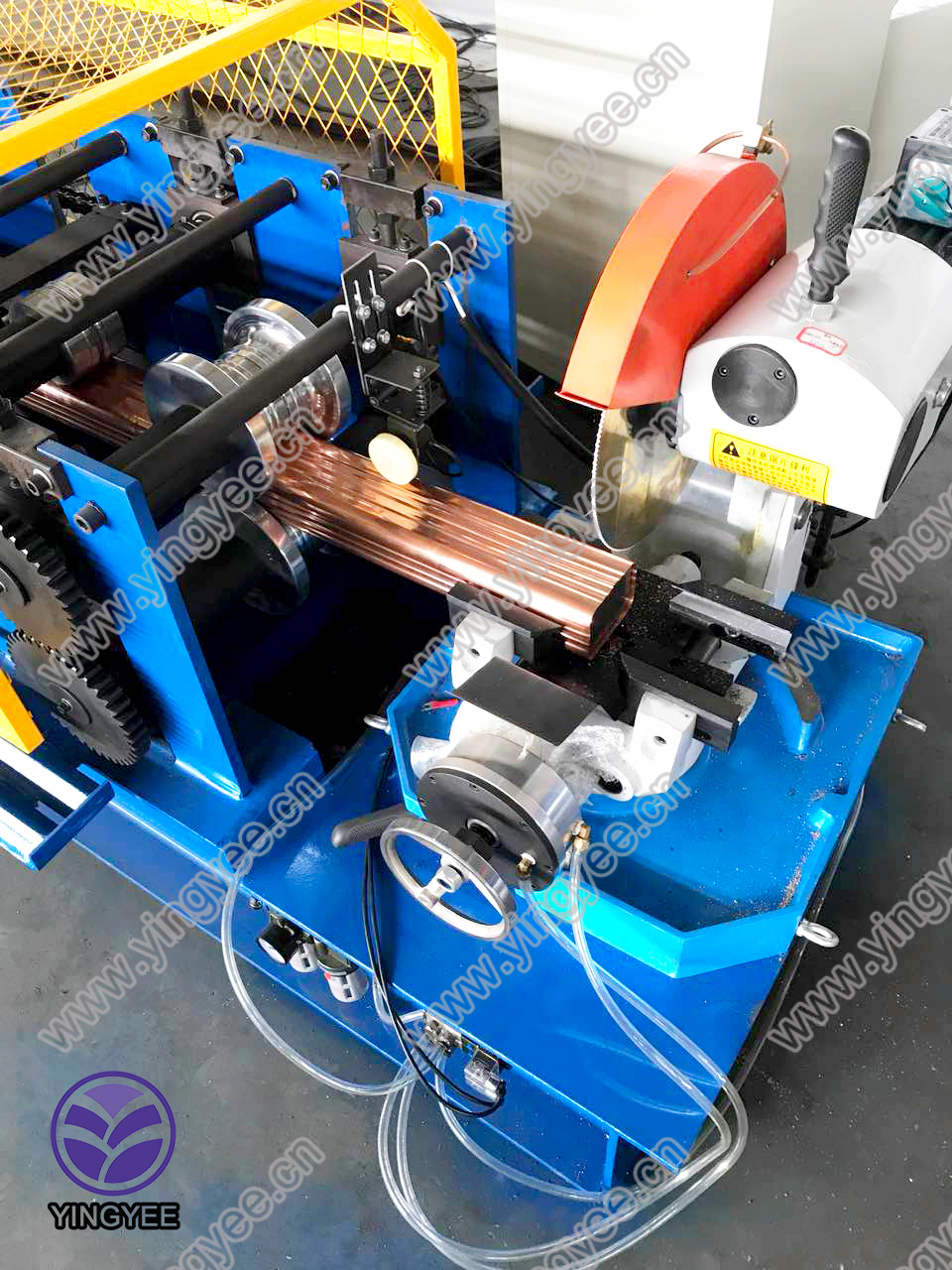

The right channel roll forming machine comes equipped with several features designed to ensure high straightness and precision in production. Firstly, the tooling design is of paramount importance. Specialized rollers are engineered to maintain uniform pressure along the length of the metal strip, thus reducing the risk of warping or bending.

Secondly, many modern machines incorporate advanced technologies such as computer numerical control (CNC) systems. These systems allow for highly accurate adjustments, ensuring that the machine consistently produces channels with minimal tolerance variations. Automated feedback systems can also monitor the straightness of products in real time, enabling the machine to make necessary adjustments on-the-fly.

Additionally, high-quality materials are often utilized in the construction of roll forming machines themselves. Sturdy frames and precision machined components minimize vibrations and movements that could affect the straightness of the finished product. This dimension of machine quality is critical in achieving the required high straightness standards.

Applications and Benefits

The applications of right channel roll forming machines with high straightness are vast. In the construction industry, these machines are used to produce metal framing, roof supports, and other structural components. In the automotive sector, they produce elements such as chassis and reinforcements that must meet stringent safety and performance standards. Appliance manufacturers also benefit from these machines to create frames for washers, dryers, and refrigerators.

The benefits of using a right channel roll forming machine extend beyond just high straightness. By streamlining production processes, manufacturers can reduce waste, minimize labor costs, and improve overall operational efficiency. Additionally, the high precision of these machines often leads to higher customer satisfaction, as clients expect reliable and durable products.

Conclusion

In conclusion, the right channel roll forming machine plays a pivotal role in producing high-straightness metal components that are essential across various industries. Advances in technology and engineering have resulted in machines that not only enhance the manufacturing process but also ensure the quality and integrity of the final products. As industries continue to evolve, the demand for precision-engineered components will undoubtedly keep the right channel roll forming machine at the forefront of manufacturing innovation.