Understanding Gypsum Channel Machines Key Features and Applications

Gypsum, a versatile and widely used mineral, plays a pivotal role in various construction applications, especially in the form of drywall and plaster. As the demand for gypsum products increases, so does the need for efficient and advanced machinery to process gypsum. One such machine that stands out in the industry is the gypsum channel machine. This article delves into the intricacies of gypsum channel machines, exploring their features, applications, and significance in the construction sector.

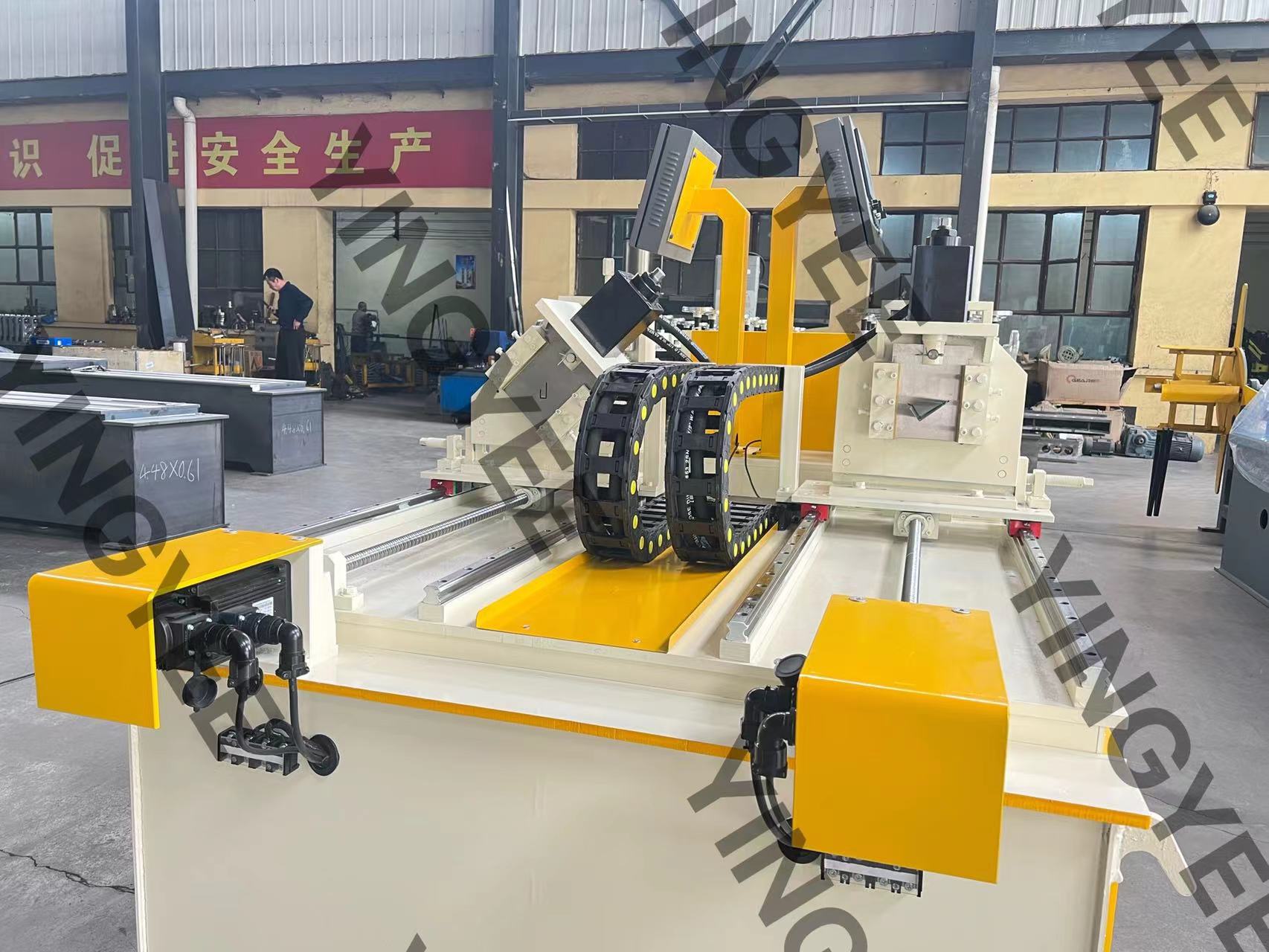

What is a Gypsum Channel Machine?

A gypsum channel machine is specifically designed to produce gypsum board and other gypsum-based products with high efficiency and precision. These machines automate the process of shaping, cutting, and finishing gypsum boards, allowing for consistent quality and increased production rates. They are essential for manufacturers looking to meet the growing demand for gypsum products in residential and commercial construction.

Key Features of Gypsum Channel Machines

1. High Production Capacity Gypsum channel machines are engineered to handle large quantities of gypsum material, making them suitable for high-volume production lines. This capacity helps meet tight deadlines in the construction industry.

2. Precision Engineering The machines are equipped with advanced technology to ensure accurate cutting and shaping of gypsum boards. This precision reduces waste and increases the overall quality of the final product.

3. User-Friendly Controls Modern gypsum channel machines come with intuitive control panels and software, allowing operators to easily adjust settings according to specific production requirements. This feature enhances the overall efficiency of the manufacturing process.

4. Durable Construction Built to withstand the rigors of continuous operation, gypsum channel machines are made from high-quality materials that ensure longevity and reliability. This durability reduces maintenance costs and downtime.

5. Energy Efficiency With an increasing focus on sustainability, many gypsum channel machines are designed to consume less energy while maintaining high productivity levels. This alignment with eco-friendly practices is essential in today's environmentally conscious market.

Applications of Gypsum Channel Machines

Gypsum channel machines find applications in various sectors within the construction industry, including

- Manufacture of Gypsum Boards These machines are primarily used to produce standard gypsum boards, which are essential for constructing walls, ceilings, and partitions. Their efficiency contributes to the rapid construction of residential and commercial buildings.

- Creation of Specialty Products Beyond standard gypsum boards, these machines can be used to produce specialty products such as fire-resistant boards, moisture-resistant boards, and decorative gypsum panels that require precise designs and dimensions.

- Plaster and Mortar Production Gypsum channel machines are also involved in the production of plasters and mortars used in building finishes. The ability to produce these materials consistently helps maintain quality across various construction projects.

The Importance of Gypsum Channel Machines in the Industry

As the construction industry evolves, the need for innovative and efficient manufacturing solutions becomes increasingly critical. Gypsum channel machines play a crucial role in this landscape by ensuring that manufacturers can keep pace with demand while maintaining high standards.

The benefits of utilizing gypsum channel machines extend beyond mere production efficiency. By automating and streamlining the production process, manufacturers can reduce labor costs, shorten lead times, and improve safety standards within their facilities. Furthermore, as environmental regulations become more stringent, these machines contribute to sustainability efforts by optimizing resource use and minimizing waste.

In conclusion, gypsum channel machines are indispensable assets in the modern construction industry. Their ability to produce high-quality gypsum products efficiently makes them vital for meeting the demands of a growing market. As technology continues to advance, we can expect to see further innovations in gypsum processing machinery, paving the way for even more efficient and sustainable solutions in the future. For manufacturers and contractors alike, investing in gypsum channel machines represents a step toward enhanced productivity and competitiveness in a rapidly changing industry.