The Evolution and Significance of Suspended Ceiling T-Grid Forming Machines

In the world of construction and interior design, the suspended ceiling has become a popular choice for commercial and residential spaces alike. This innovative design not only enhances aesthetics but also improves acoustics and facilitates easier access to essential systems like HVAC, plumbing, and electrical wiring. At the heart of this suspended ceiling system lies the T-grid framework, a crucial component that holds the ceiling tiles in place. The machinery used to create these T-grids—suspended ceiling T-grid forming machines—has evolved significantly, playing an indispensable role in the manufacturing process.

Understanding T-Grid Systems

Before delving into the machines themselves, it’s important to understand what T-grid systems are. A T-grid is essentially a grid-type framework, usually made of lightweight metal, which forms a supporting structure for suspended ceiling tiles. The T refers to the shape of the grid layout, resembling a series of T-shaped supports arranged in a square or rectangular pattern. This grid system allows for individual ceiling tiles to be easily replaced or removed when maintenance is required, offering flexibility and convenience.

The Role of T-Grid Forming Machines

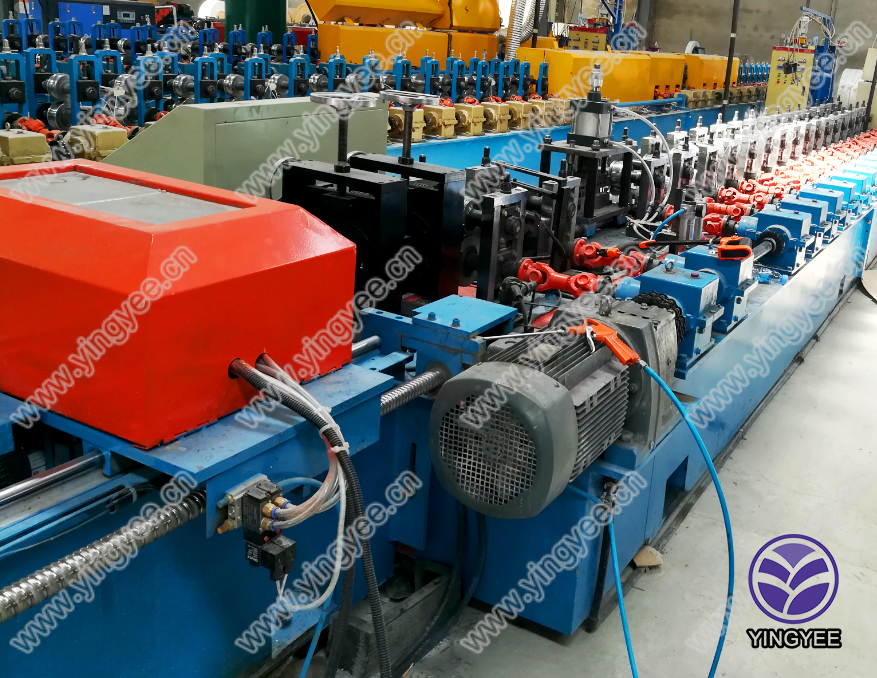

T-grid forming machines are specialized equipment designed to fabricate the metal components used in T-grid systems. These machines efficiently take raw metal sheets and process them into precise grid shapes required for ceiling construction. The technologies behind these machines have advanced over the years, incorporating automation, computer numerical control (CNC), and high-speed processing capabilities.

1. Automation and Efficiency Modern T-grid forming machines are equipped with automated features that streamline the entire production process. This leads to increased output and reduced labor costs. The automation not only speeds up the forming process but also enhances accuracy, ensuring that the dimensions of each grid element are consistent and up to standard.

2. CNC Technology CNC technology allows for precise cutting and shaping of the metal sheets. This innovation has transformed manufacturing from manual processes to highly controlled, computer-driven operations. As a result, the machines can produce complex designs with minimal human intervention, decreasing the likelihood of errors that could render components unusable.

3. Material Versatility Nowadays, T-grid forming machines can work with a variety of materials, including galvanized steel, aluminum, and even certain composites. This versatility enables manufacturers to cater to different aesthetic preferences and performance requirements, ultimately meeting a wide range of customer needs.

4. Sustainability With the construction industry increasingly prioritizing sustainability, modern T-grid forming machines can also accommodate eco-friendly practices. Many machines are designed to minimize material waste during the forming process, and manufacturers are often opting for recycled materials to produce their T-grids. This aligns with the growing trend towards green building practices and sustainability.

Market Demand and Future Trends

The demand for suspended ceilings and, consequently, T-grid forming machines remains robust, driven by commercial construction, office refurbishments, and the rising popularity of open-plan living in residential spaces. As the architectural landscape continues to evolve, so do the needs for innovative ceiling solutions.

Moving forward, we can expect further advancements in T-grid forming technology. Developments like Industry 4.0, which emphasizes interconnected machines and data-driven processes, will likely play a significant role. Enhanced predictive maintenance tools, powered by artificial intelligence, will ensure that T-grid forming machines operate more efficiently and with fewer downtimes.

Conclusion

Suspended ceiling T-grid forming machines represent a vital component of the construction industry, contributing significantly to the functional and aesthetic aspects of interior spaces. With ongoing innovations and a shift towards sustainable practices, these machines are set to become even more integral in the future. As we look ahead, it is clear that the T-grid manufacturing process will continue to adapt, ensuring that it meets the evolving demands of architects, builders, and homeowners alike.