The unsung hero of modern warehousing and retail environments is undoubtedly the shelf rack upright roll forming machine. This specialized equipment not only revolutionizes how industrial shelving and storage solutions are manufactured but also plays a pivotal role in optimizing space efficiency and material handling processes. As a seasoned SEO professional, I delve into the intricacies of this machine, imparting both technical insights and practical experiences gained over years of observing its impact on industry operations.

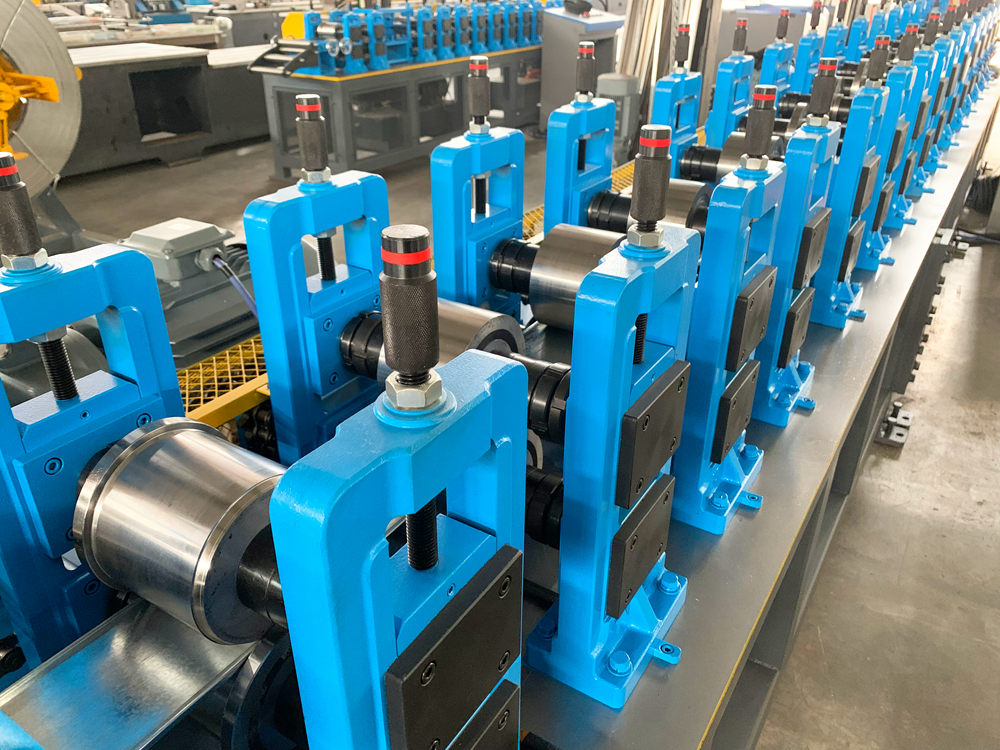

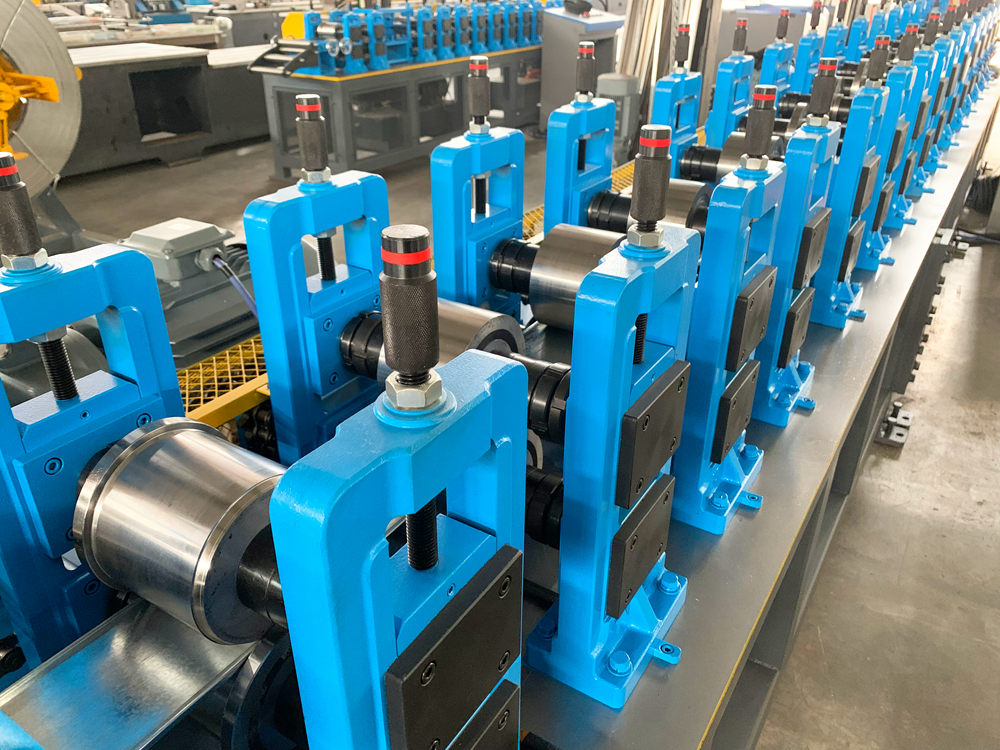

Crafted from high-quality steel, an upright shelf rack serves as the backbone of racking systems. The roll forming machine automates the transformation process from raw material to finished product with precision and consistency. When discussing the mechanical prowess of a shelf rack upright roll forming machine, its pivotal attribute is its ability to continuously shape long strips of metal into desired cross-sectional profiles through a series of carefully calibrated rollers. This automation reduces labor costs significantly while enhancing production speed, a factor critically linked to the supply chain's responsiveness and flexibility.

The entrancing technicality of these machines lies in their computerized control systems. Advanced machines are equipped with PLCs (Programmable Logic Controllers) which enable intricate adjustments and real-time monitoring. This means greater precision and customization potential. My experience confirms that adopting a well-optimized roll forming machine can lead to extended operational uptime and reduced waste, direct contributors to profitability and sustainability in manufacturing environments.

Expert operators of roll forming machines demonstrate a confluence of craftsmanship and technological acumen. Proper training in handling this machinery ensures not only smooth operations but also preserves the longevity of the equipment and the safety of warehouse personnel. Over the years, firms that integrate on-site training programs report higher efficiency levels and minimized downtimes, reinforcing the machine's reputation as a robust investment.

shelf rack upright roll forming machine

Manufacturers prioritize sourcing steel with consistent and superior tensile strength, ensuring the end product – shelf rack uprights – sustains heavy loads and long-term wear. The roll forming process also improves the mechanical properties of metal by imparting work hardening, thus increasing the shelf rack's strength against buckling – an assurance of reliability for end-users storing bulk and oversized goods.

The integration of environmentally friendly practices in roll forming technology is a noteworthy advancement. Today's machines are designed with sustainable production in mind, utilizing energy-efficient systems and reducing carbon footprints. As industries pivot toward green initiatives, the environmental benefits offered by modern shelf rack upright roll forming machines cannot be overstated. Opting for machinery with this eco-friendly orientation oftentimes aligns companies with global sustainability standards while enhancing their brand reputation.

Trust in the integrity of a machine is cemented through reputable certifications. ISO and other international standard certifications offer assurance of quality and safety. Leading manufacturers of roll forming machines often boast such accreditation, reinforcing clients' confidence in their investment. Ensuring that the machine procured meets these stringent standards is vital for any enterprise seeking to maintain competitive advantage in the international market.

In conclusion, the shelf rack upright roll forming machine exemplifies a blend of engineering sophistication and operational excellence. It stands as a testament to the transformative potential of modern automation within the industrial sector. By investing in such technology, businesses not only safeguard their operational capacity but strategically position themselves for future growth. This journey of utilizing such innovative machinery underscores the criticality of combining practical experience, specialized knowledge, authoritativeness, and a commitment to trustworthy operations in today’s dynamic market landscape.