The Importance of Galvanized Cable Tray Roll Forming Machines

In the modern industrial landscape, efficient cable management solutions are essential for ensuring safety, organization, and operational efficiency. One of the most effective ways to achieve this is through the use of galvanized cable trays. These trays, designed to manage and support electrical and communication cables, are crucial in various applications, from industrial plants to commercial buildings. To manufacture these cable trays efficiently, the galvanizing cable tray roll forming machine plays a pivotal role.

Understanding Roll Forming Technology

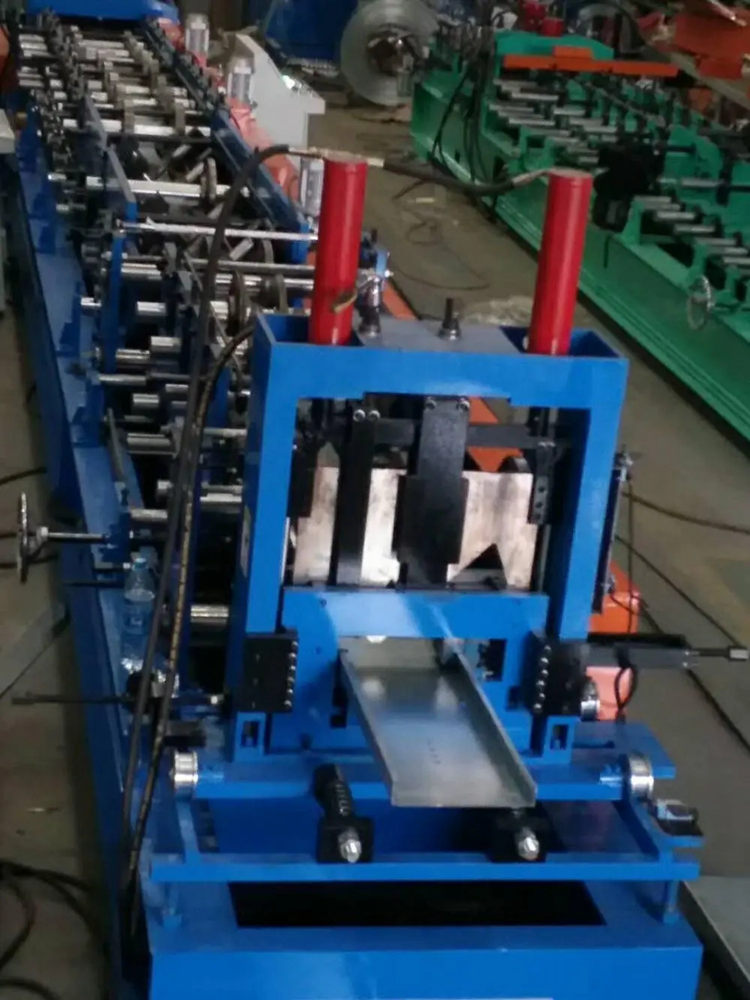

Roll forming is a continuous metal forming process that converts flat metal sheets into specific shapes through a series of roller stations. The process is highly efficient, providing consistent product quality and various design options, making it ideal for producing cable trays. The galvanized cable tray roll forming machine is specifically designed to produce trays that not only meet functional requirements but also withstand environmental challenges due to their galvanized finish.

Advantages of Galvanizing

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent corrosion. This is particularly vital for cable trays, which are often exposed to elements that can cause rust and degradation over time. The galvanized cable trays produced by these machines offer several benefits

1. Durability Galvanized trays have a longer lifespan compared to their non-galvanized counterparts, making them a cost-effective choice in the long term. 2. Maintenance These trays require minimal maintenance, as the galvanized coating protects them from oxidation and weather-related damages. 3. Safety The robustness of galvanized trays ensures that cables are securely held, reducing the risk of accidents due to cable wear or failure.

Applications of Galvanized Cable Trays

Galvanized cable trays are widely used across various industries, including

- Electrical In commercial and industrial settings, these trays support a vast network of electrical cabling, providing an organized method for routing wires and enhancing safety. - Telecommunications They are essential in housing communication wires in an organized manner, thus preventing tangling and reducing the risk of signal interference. - Data Centers With the rise of data centers, there is an increasing need for efficient cable management solutions. Galvanized trays enable easy access and improved airflow around equipment, ensuring optimal performance.

Features of Roll Forming Machines

A quality galvanized cable tray roll forming machine should boast several features

1. Precision Machines must ensure accurate dimensions, which is critical for the integrity and safety of the cable handling system. 2. Speed High production speeds without compromising quality allows manufacturers to keep up with market demands. 3. Flexibility Modern roll forming machines can be easily adjusted to produce various tray sizes and designs to meet specific customer requirements. 4. User-Friendly Interface Advanced machines come equipped with intuitive controls that simplify operation and reduce the learning curve for new operators.

Conclusion

The galvanized cable tray roll forming machine is indispensable for producing high-quality cable management solutions. Its ability to efficiently manufacture durable, safe, and low-maintenance trays caters to the diverse needs of various industries. As technology continues to advance, these machines are expected to evolve, integrating features like automation and smart technology, further enhancing production capabilities. Investing in quality roll forming machinery not only boosts productivity but also supports the critical infrastructure that keeps our electrical and telecommunications systems running smoothly. Thus, the importance of these machines within the manufacturing process cannot be overstated—they are a cornerstone of modern industry.