The Importance of Roofing Sheet Roll Forming Machines in Modern Construction

In the ever-evolving landscape of construction and architectural design, the demand for durable and aesthetically pleasing building materials continues to rise. Among these materials, roofing sheets play a crucial role in both functionality and appearance. Roofing sheet roll forming machines have emerged as essential tools in the production of high-quality roofing sheets, offering numerous benefits and shaping the future of the construction industry.

Roofing sheet roll forming machines are specialized equipment designed to create roofing sheets from metal strips. They operate through a continuous process that involves feeding metal coils into the machine, which then shapes and cuts them into the desired profiles. This process ensures a consistent and efficient production of roofing sheets, allowing manufacturers to meet the increasing demands of construction projects.

One of the primary advantages of using roofing sheet roll forming machines is their efficiency. Traditional methods of roofing sheet production often involve labor-intensive processes that can be time-consuming and costly. However, roll forming machines streamline this process, reducing labor costs and minimizing waste. This not only enhances productivity but also contributes to a more sustainable manufacturing process by maximizing material usage.

Moreover, roofing sheet roll forming machines offer unmatched precision in the production of roofing sheets. The use of advanced technology allows for accurate control over the dimensions and specifications of the sheets. This precision is crucial, as roofing materials must fit perfectly to ensure durability and prevent issues such as leaks and structural failures. With the ability to customize sheet profiles, manufacturers can cater to specific architectural designs, providing flexibility to architects and builders alike.

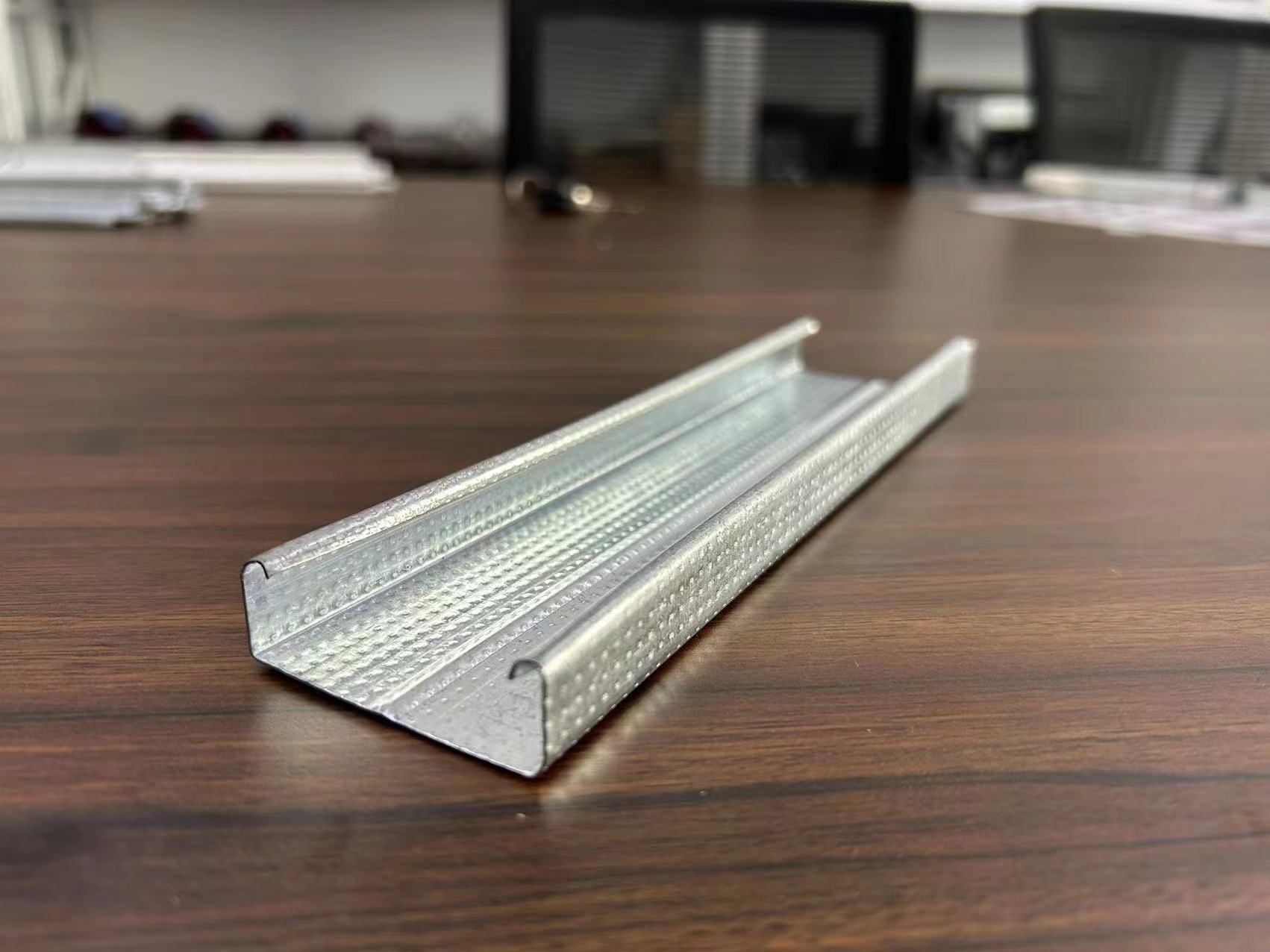

In addition to efficiency and precision, roofing sheet roll forming machines are highly versatile

. They can produce a variety of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This versatility allows manufacturers to respond to diverse market needs, as different construction projects may require specific roofing styles. Furthermore, the machines can accommodate various materials, including galvanized steel, aluminum, and copper, enabling a wide range of applications across different types of buildings.Another significant benefit of roofing sheet roll forming machines is their ability to enhance the aesthetics of buildings. With the rise of architectural designs that prioritize visual appeal, the demand for attractive roofing materials has increased. Roll forming machines can create sheets with intricate designs, textures, and finishes, contributing to the overall look of a structure. By providing high-quality, visually appealing roofing sheets, manufacturers can help builders create stunning buildings that stand out in urban landscapes.

As the construction industry continues to advance, the role of roofing sheet roll forming machines is expected to grow. The integration of automation and smart technology into these machines will likely lead to even greater efficiencies and production capabilities. Innovations such as predictive maintenance and remote monitoring will enable manufacturers to optimize their production processes, reduce downtime, and enhance the quality of their products.

In conclusion, roofing sheet roll forming machines represent a significant advancement in the production of roofing materials. Their ability to deliver efficiency, precision, versatility, and aesthetic appeal makes them indispensable in modern construction. As the demand for high-quality roofing solutions continues to rise, investing in advanced roll forming technology will empower manufacturers to meet the challenges of the future, ensuring that the buildings of tomorrow are equipped with durable and attractive roofing systems.