Understanding Elbow Forming Machine Manufacturers A Comprehensive Guide

In the world of manufacturing, the demand for precision and efficiency cannot be overstated. One crucial component in many industries, particularly those related to piping and tubing, is the elbow forming machine. These specialized machines allow manufacturers to create curved piping components that facilitate the seamless flow of fluids in various applications. This article delves into elbow forming machine manufacturers, exploring their importance, key features, and considerations for choosing the right manufacturer.

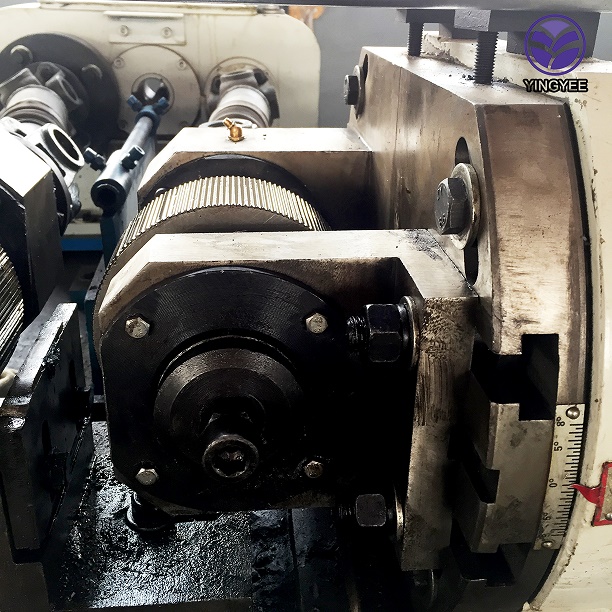

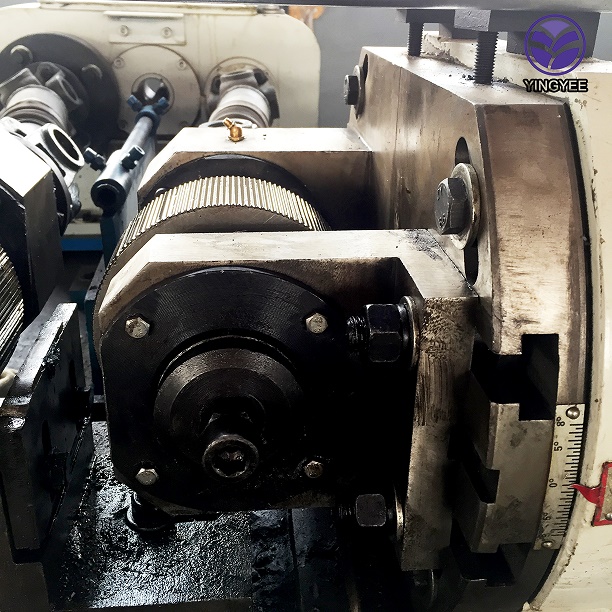

What is an Elbow Forming Machine?

An elbow forming machine is designed to fabricate elbow fittings from various materials, including metal and plastic. These machines are vital for industries such as plumbing, HVAC, oil and gas, and others where fluid transport is essential. The machines enable manufacturers to produce high-quality elbow fittings that match specific dimensions and angles, ensuring proper flow dynamics and reducing the risk of leaks.

Importance of Elbow Forming Machine Manufacturers

With the growing complexity of industrial systems, the importance of robust and efficient elbow forming machines has surged. Manufacturers specializing in these machines play a critical role in ensuring that businesses can produce the components they need with consistency and accuracy. Here are some reasons why selecting a reputable elbow forming machine manufacturer is essential

1. Quality Assurance Established manufacturers adhere to stringent quality control measures to ensure that their machines produce reliable and durable products. This is critical for businesses that depend on these machines for consistent output.

2. Technological Advancements The industry continues to evolve with technological innovations, including automation and precision engineering. Leading manufacturers invest in research and development to stay ahead, providing clients with the latest features and capabilities.

3. Customization Different industries have varying requirements regarding elbow fittings. A good manufacturer can offer customization options to suit specific needs, whether it’s the angle, diameter, or material used.

4. Support and Service After purchasing an elbow forming machine, ongoing support is essential. Reputable manufacturers provide maintenance services and technical support, ensuring that machines operate smoothly over their lifespan.

Key Features of Elbow Forming Machines

When evaluating manufacturers, it’s essential to consider the key features of their elbow forming machines

- Material Versatility Many machines are designed to work with different materials, including stainless steel, carbon steel, PVC, and more, providing versatility for manufacturers

.

elbow forming machine manufacturers

- Angle Precision The ability to produce elbows at precise angles is crucial for ensuring optimal flow and minimizing turbulence within piping systems.

- Production Speed High-efficiency machines can significantly speed up the production process, enabling manufacturers to meet demanding schedules and reduce labor costs.

- User-Friendly Controls Intuitive control systems help operators manage production easily, enhancing operational efficiency and reducing training time.

Considerations When Choosing a Manufacturer

Selecting the right elbow forming machine manufacturer requires careful consideration of several factors

1. Reputation and Experience Look for manufacturers with a solid reputation in the industry. Established companies are more likely to provide dependable products and services.

2. Customer Reviews and Testimonials Research customer feedback to gain insight into their experiences with the manufacturer. Positive reviews can indicate reliability and effectiveness.

3. Warranty and Guarantee A robust warranty can provide peace of mind, ensuring that the investment is protected in case of defects or issues in manufacturing.

4. Post-Sale Support Assess the level of post-sale support offered. Manufacturers that provide ongoing maintenance and training can help ensure that you get the best from your equipment.

5. Pricing While cost is an important consideration, it should not be the sole factor in your decision. Analyze the overall value offered, including features, support, and build quality.

Conclusion

Elbow forming machines are indispensable tools for various industries that require reliable and efficient piping solutions. By understanding the importance of elbow forming machine manufacturers and considering their offerings carefully, businesses can make informed decisions that enhance their operational capabilities. The right manufacturer can be a valuable partner in achieving quality production and driving business success in today’s competitive landscape.