Advancements in Roofing Sheet Cutting Machines

The construction industry is constantly evolving, with the demand for efficient and precise machinery at an all-time high. One such innovation that has made a significant impact is the roofing sheet cutting machine. These machines have revolutionized the way roofing materials are processed, providing contractors and manufacturers with the tools necessary to improve efficiency, reduce waste, and enhance the overall quality of roofing installations.

Roofing sheets are widely used in residential, commercial, and industrial construction due to their durability and versatility. However, the cutting of these sheets can be a labor-intensive and time-consuming process if done manually. This is where roofing sheet cutting machines come into play. Designed to accurately cut sheets to specific dimensions, these machines save both time and labor, allowing workers to focus on other crucial aspects of their projects.

One of the primary advantages of modern roofing sheet cutting machines is their precision. Traditional manual cutting methods often lead to inaccurate measurements and uneven cuts, resulting in material wastage and potential delays in construction. In contrast, state-of-the-art cutting machines utilize advanced technology, including computerized controls and laser cutting systems, which ensure high accuracy in the cutting process. This precision not only minimizes waste but also guarantees that the roofing sheets fit perfectly during installation, reducing the risk of leaks and other issues in the future.

Furthermore, roofing sheet cutting machines are designed for versatility. They can handle a variety of materials, including metal, plastic, and composite sheets. This versatility enables manufacturers to diversify their product offerings and cater to different market needs. Moreover, many of these machines come equipped with adjustable settings, allowing operators to customize the cutting process based on the specific requirements of each project. This adaptability is crucial in a fast-changing industry where customer demands can vary significantly.

The speed at which roofing sheet cutting machines operate is another noteworthy benefit. In an industry where time is money, faster cutting processes mean quicker turnarounds on projects. Many modern machines are capable of cutting multiple sheets simultaneously, significantly increasing production rates. This efficiency not only helps builders meet tight deadlines but also contributes to cost savings, enhancing overall project profitability.

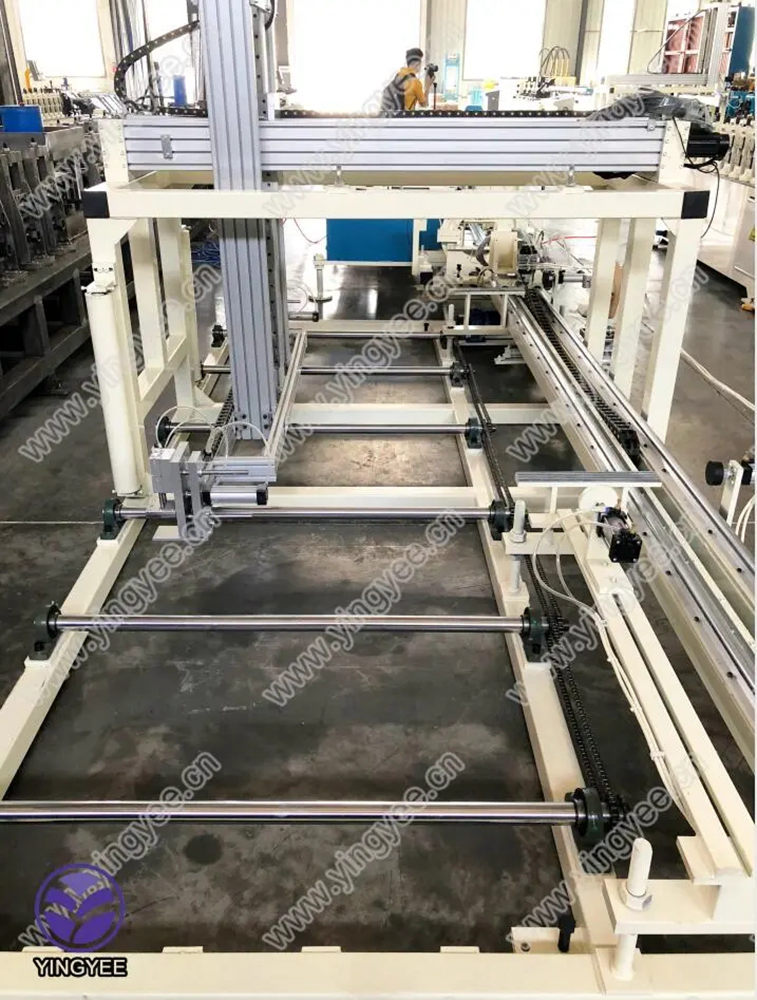

Additionally, advancements in technology have led to the introduction of automation in roofing sheet cutting machines. Automated systems can streamline the entire cutting process, from material handling to cutting and even packaging. This automation reduces the need for manual intervention, which minimizes errors and labor costs. With fewer personnel required on-site, companies can allocate resources more effectively, leading to increased overall productivity.

While the initial investment in roofing sheet cutting machines may seem high, the long-term benefits can be substantial. Companies that incorporate these machines into their operations often experience lower operational costs due to enhanced efficiency and reduced waste. Additionally, the improved quality of cut sheets leads to better roofing installations, which can enhance a company's reputation in the market.

In conclusion, roofing sheet cutting machines are indispensable tools in modern construction. Their precision, versatility, speed, and automation capabilities significantly enhance the efficiency of the roofing material cutting process. As the industry continues to grow and evolve, investing in such technology will likely be a key factor in maintaining competitiveness and achieving success in the ever-demanding construction landscape. Whether for small-scale residential projects or large commercial ventures, roofing sheet cutting machines are poised to play a pivotal role in the future of construction.