The Role of CZU Steel Purlin Frame Roll Forming Machine in Modern Construction

In the realm of modern construction, efficiency and structural integrity are paramount. One of the key innovations that has significantly enhanced the speed and quality of building processes is the CZU steel purlin frame roll forming machine. This advanced piece of machinery plays a vital role in the production of steel purlins, which are essential components in the construction of industrial buildings, warehouses, and other structures.

Understanding Steel Purlins

Steel purlins are horizontal structural members that support the roof decking or sheathing of a building. They offer strength, stability, and support, making them critical for ensuring the durability of frameworks. Traditionally, purlins were made from timber or heavier steel sections, which not only increased the construction weight but also made handling and installation more complex. With the advent of roll forming technology, the production of lightweight yet robust steel purlins has transformed the industry.

What is a CZU Steel Purlin Frame Roll Forming Machine?

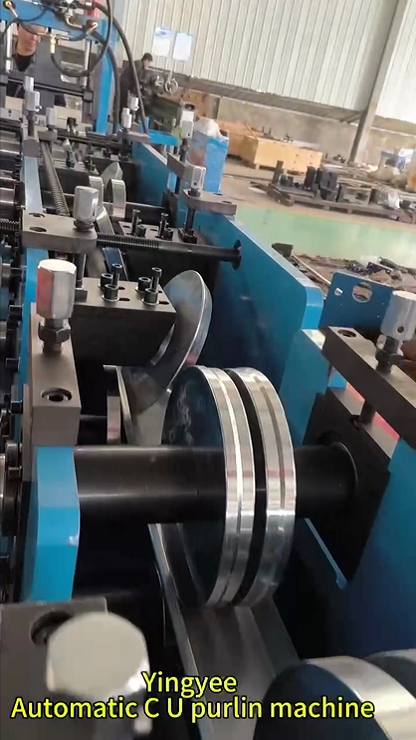

The CZU steel purlin frame roll forming machine is a specialized equipment designed to fabricate high-quality steel purlins efficiently. It employs a process known as roll forming, where a continuous strip of metal is fed through a sequence of rollers that gradually shape it into the desired profile. The machine is capable of producing various types of purlin profiles, including C, Z, and U shapes, which can be customized according to specific project requirements.

Advantages of Using CZU Steel Purlin Frame Roll Forming Machine

czu steel purlin frame roll forming machine

1. Efficiency and Speed One of the standout features of the CZU machine is its ability to produce purlins at a rapid rate. This efficiency translates to shorter lead times in construction projects, allowing contractors to meet deadlines and reduce labor costs.

2. Precision Manufacturing The roll forming process ensures consistent thickness and dimensional accuracy, reducing the likelihood of errors that can occur with traditional fabrication methods. This precision contributes to the overall quality of the structure.

3. Material Conservation By utilizing the roll forming technique, the CZU machine minimizes material waste. The process allows for tighter tolerances, ensuring that more of the raw material is transformed into usable purlins rather than scrap.

4. Versatility The machine can be adjusted to produce different sizes and shapes of purlins, making it a versatile tool for various construction projects. This adaptability allows contractors to optimize their designs without the need for multiple machines.

5. Cost-Effectiveness With reduced material and labor costs, the use of the CZU steel purlin frame roll forming machine significantly enhances the overall cost-effectiveness of construction projects. Additionally, the durability of steel purlins minimizes maintenance costs in the long run.

Conclusion

The CZU steel purlin frame roll forming machine is a game changer in the construction industry, epitomizing the blend of speed, efficiency, and versatility. As the demand for robust and lightweight materials continues to rise, the role of such advanced machinery will only become more critical. By investing in these machines, construction firms can not only improve their operational efficiency but also ensure high-quality outputs that meet the demands of modern building standards. The integration of technology in construction processes, exemplified by the CZU machine, is undoubtedly paving the way for a more sustainable and efficient future in the industry.