The IBR Roof Machine Revolutionizing Roofing Solutions

In the construction and manufacturing industry, efficiency and precision are paramount. One of the innovations that have greatly impacted the roofing sector is the IBR (Inverted Box Rib) roof machine. This specialized equipment is designed to streamline the production of metal roofing sheets, enhancing both the speed and quality of output.

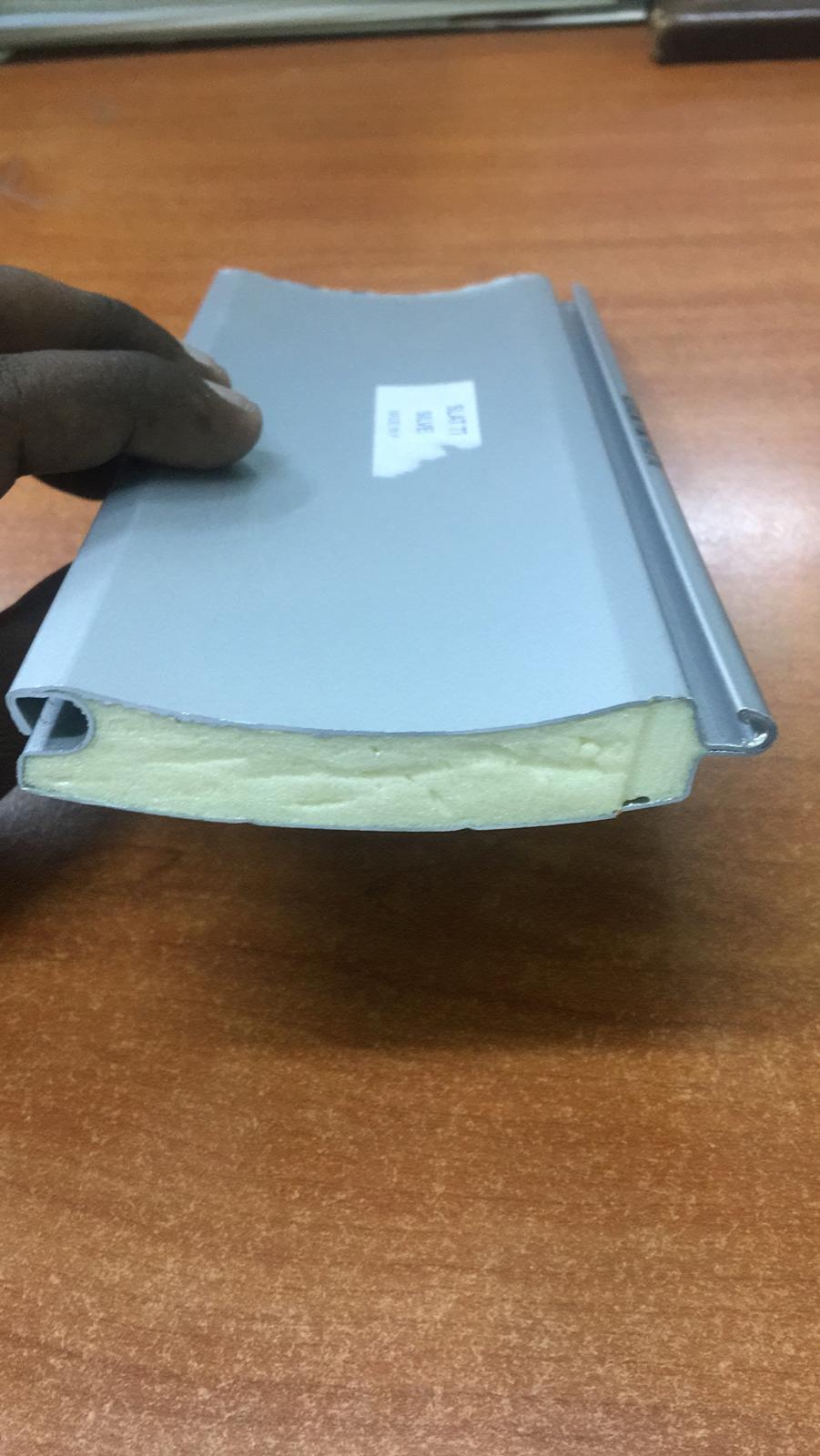

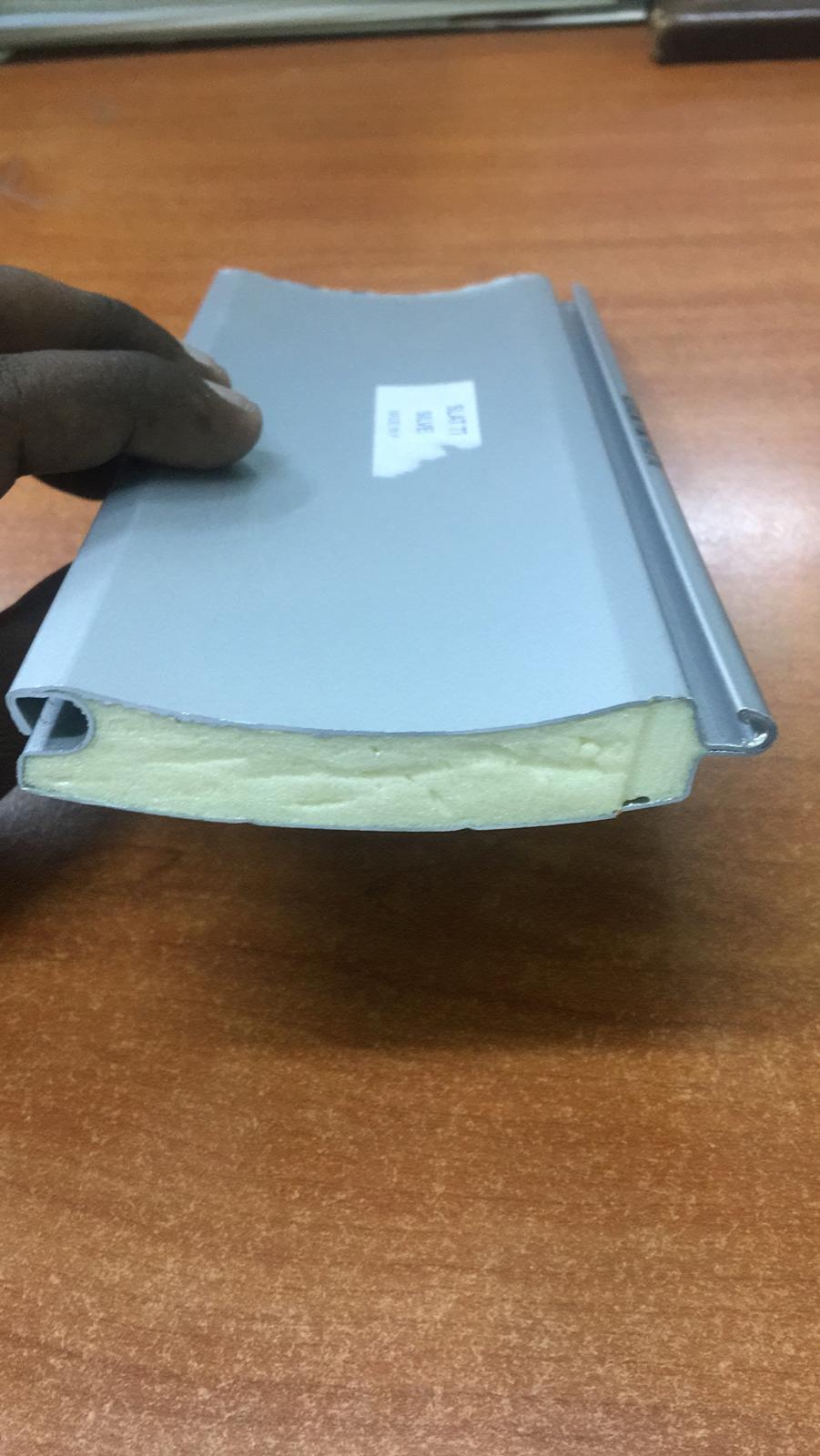

Understanding the IBR Profile

The IBR roof profile is characterized by its unique ribbed structure. The inverted box rib design is not only aesthetically pleasing but also significantly improves the strength and durability of the roofing material. This profile is particularly popular in commercial and industrial building applications, where robust roofing solutions are essential. Its design allows for excellent water runoff, reducing the risk of leaks and ensuring longevity in various weather conditions.

Efficiency and Precision in Production

The IBR roof machine automates the process of shaping and forming metal sheets into the IBR profile. This automation is a game-changer for manufacturers, as it allows for rapid production without compromising on quality. Traditional methods of roofing sheet production often require manual labor, leading to inconsistencies and a greater margin for error. In contrast, the IBR roof machine utilizes advanced technologies, including computerized controls, to ensure that each sheet meets precise specifications.

One of the significant advantages of using the IBR roof machine is its capacity for high output. Manufacturers can produce thousands of sheets in a single day, which is crucial for meeting project deadlines and handling large-scale orders. This efficiency not only saves time but also reduces labor costs, making it a financially sound investment for businesses in the roofing industry.

Versatility and Customization

ibr roof machine

The IBR roof machine offers remarkable versatility, allowing producers to create sheets in various materials such as galvanized steel, aluminum, and even color-coated substrates. Furthermore, the machine can be adjusted to produce different widths and lengths of roofing sheets based on specific project requirements. This level of customization caters to diverse architectural styles and functional needs, ensuring that clients receive tailored products that meet their expectations.

Environmental Considerations

In an era where sustainability is increasingly important, the IBR roof machine promotes environmentally friendly practices. Metal roofing is known for its recyclability, and the efficient production processes of the IBR machine minimize waste generated during manufacturing. Additionally, many metal roofing materials come with energy-saving properties, reflecting heat and contributing to lower energy consumption in buildings.

The Future of Roofing Manufacturing

The innovative design and capabilities of the IBR roof machine are steering the roofing industry toward a more advanced future. As technology continues to evolve, manufacturers can expect even more enhancements, including integration with smart manufacturing systems and IoT (Internet of Things) applications. Such advancements will enable real-time monitoring of production processes, further improving efficiency and quality control.

Conclusion

In conclusion, the IBR roof machine stands as a pivotal development in the roofing manufacturing sector. Its ability to produce high-quality, durable roofing sheets quickly and efficiently makes it an indispensable tool for businesses. As the demand for superior roofing solutions continues to grow, the IBR roof machine is not just a trend but a vital component in the evolution of construction practices. Embracing this technology will undoubtedly lead to better outcomes in terms of cost, time, and sustainability, ensuring that the roofing industry continues to thrive in the years to come.