For this machine, we set the flow chart as this:

Decoiler→16tons punching machine→Roll forming→Cutting part→Receiving table

|

Decoiler

|

2 Tons Hydraulic decoiler with feeder

|

|

Punching machine

|

16 tons punching machine with servo feeder

A set of mould

One time punching 6 holes

|

|

Roll forming machine

|

Main power : 5.5kw

Wall panel: standing plate with iron casting

Forming speed: no stop cutting, speed 0-16m/min

Shaft material and diameters: #45 steel and 50mm

Roller material:Cr12 with well heat treatment ,58-62

Forming Steps: 10 steps for forming

Driven: Chain

Change size by manual by spacer

Voltage : 380v ,50HZ,3 phase

|

|

Cutting part

|

Hydraulic cutting system

Material: Cr12

Hydraulic station:4.0kw

Servo motor:1.5kw

|

|

Receiving table

|

No power

|

|

Cover area

|

Length 20m* width 1.5m

|

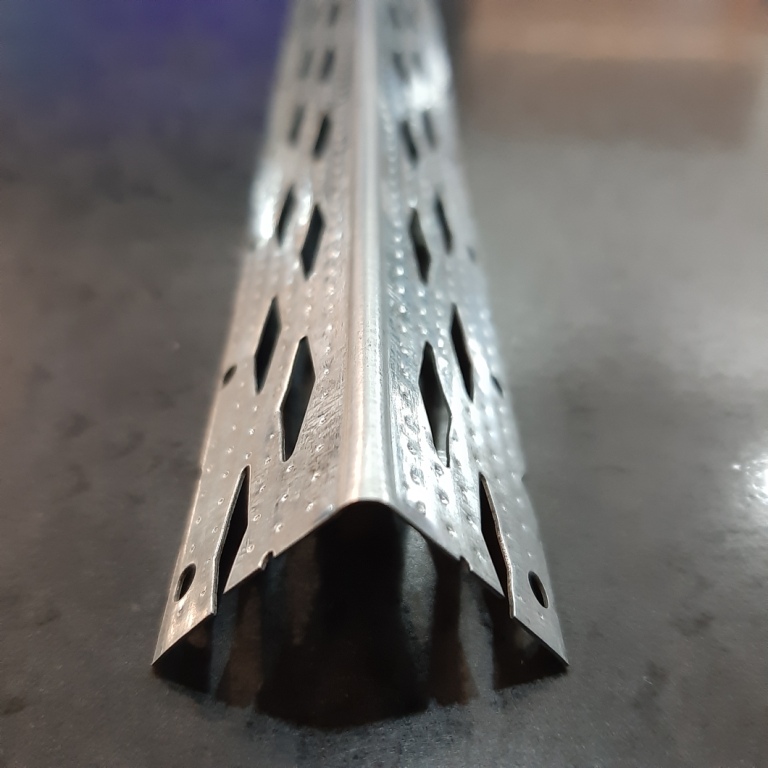

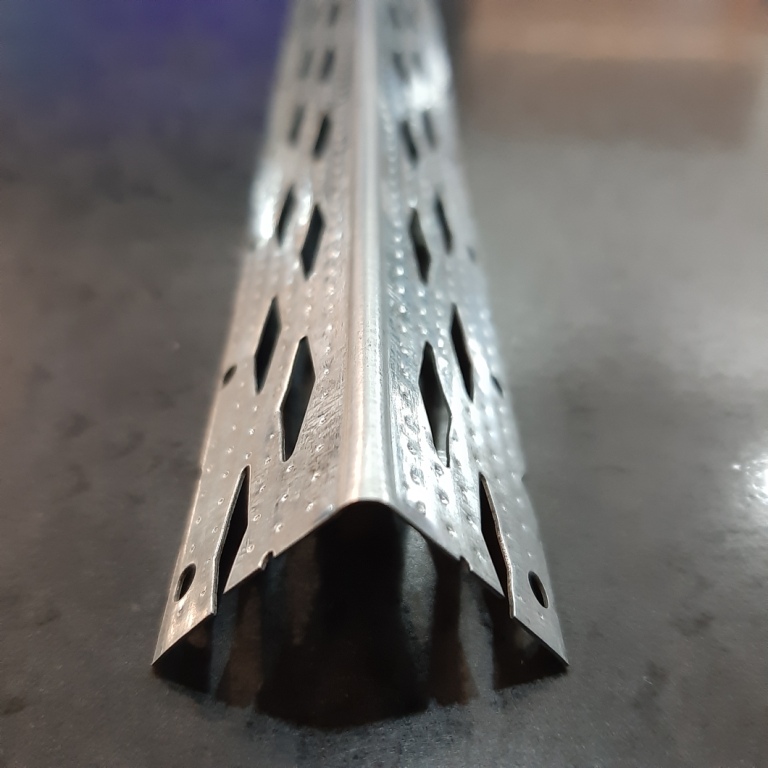

Corner bead

Edge bead