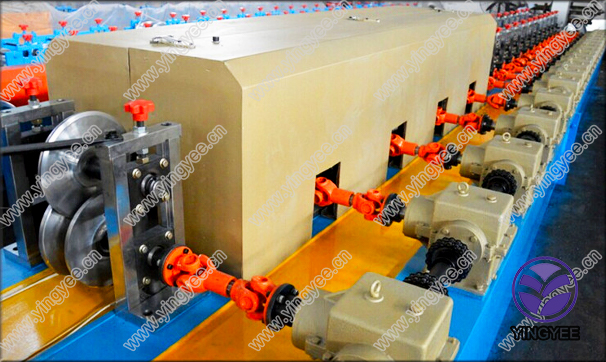

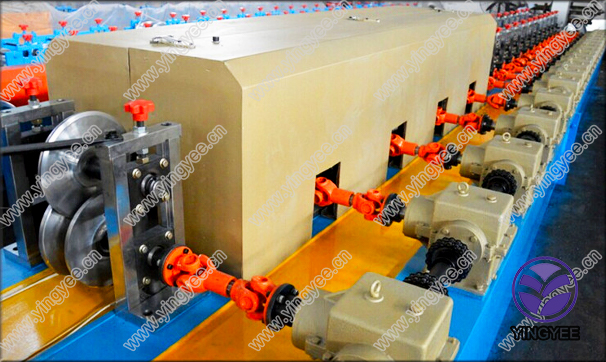

For the PU roller shutter door roll forming machine, the following is the flow chart:

Put the steel coil on the un-coiler→Guiding→Warm box(heathen the material)→ Roll-forming Machine→Injection machine → roll forming machine→Warm box(help expanding) →Adjusting device → Punching device→Flying saw cutting→Run out table

And here are some parameters of the pu roller shutter door roll forming machine:

|

No.

|

Items

|

Spec:

|

|

1

|

Material

|

1. Thickness: 0.18-0.35 mm;

2. Effective width:45mm

|

|

2

|

Power supply

|

380V, 50Hz, 3 phase(Or customized)

|

|

3

|

Speed

|

Line speed: 8-12m/min

|

|

4

|

Dimension

|

Approx.(L*W*H) 30360mm*2010mm

|

|

5

|

Stands of rollers

|

38 rollers

|

|

6

|

Cut style

|

Flying saw cutting

|