Coil cutting to length is an essential process in the manufacturing industry that involves cutting metal coils into specified lengths. This process can be done using a variety of methods, including shearing, slitting, or sawing. The resulting flat sheets or strips can then be used for a wide range of applications, from automotive parts to roofing materials.

One of the main advantages of coil cutting to length is its efficiency. By cutting metal coils into specific lengths, manufacturers can significantly reduce waste and increase production speed. This is especially important in industries where precision and consistency are key requirements. Additionally, coil cutting to length allows for greater flexibility in meeting customer demands for custom sizes and shapes.

Shearing is one of the most common methods used for coil cutting to length. In this process, a blade is used to cut the metal coil into individual sheets or strips. Shearing is preferred for its speed and accuracy, making it ideal for high-volume production runs.

Another method, slitting, involves cutting the metal coil into narrower strips coil cutting to length

coil cutting to length. Sawing, on the other hand, uses a rotating blade to cut through the metal coil.

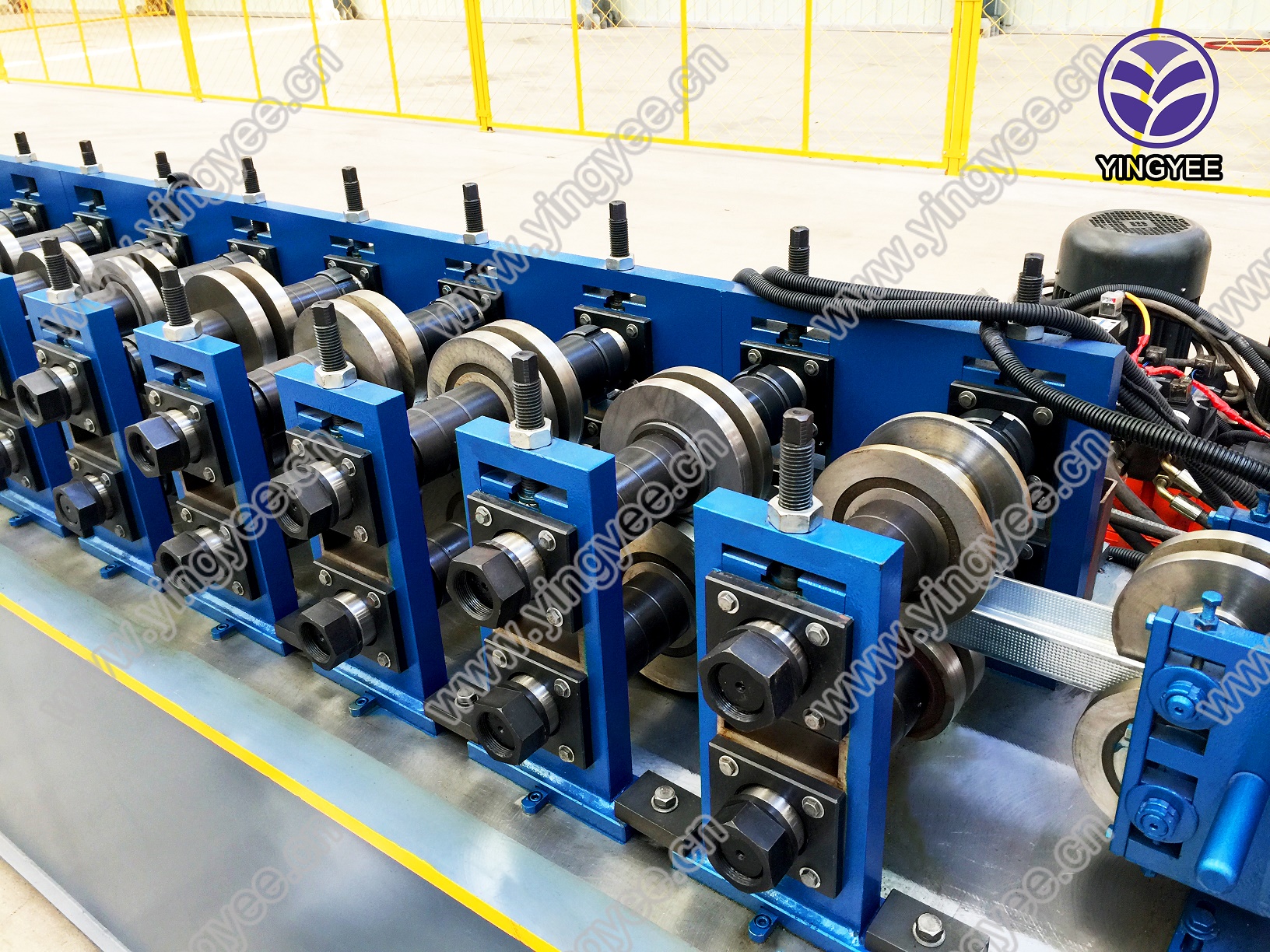

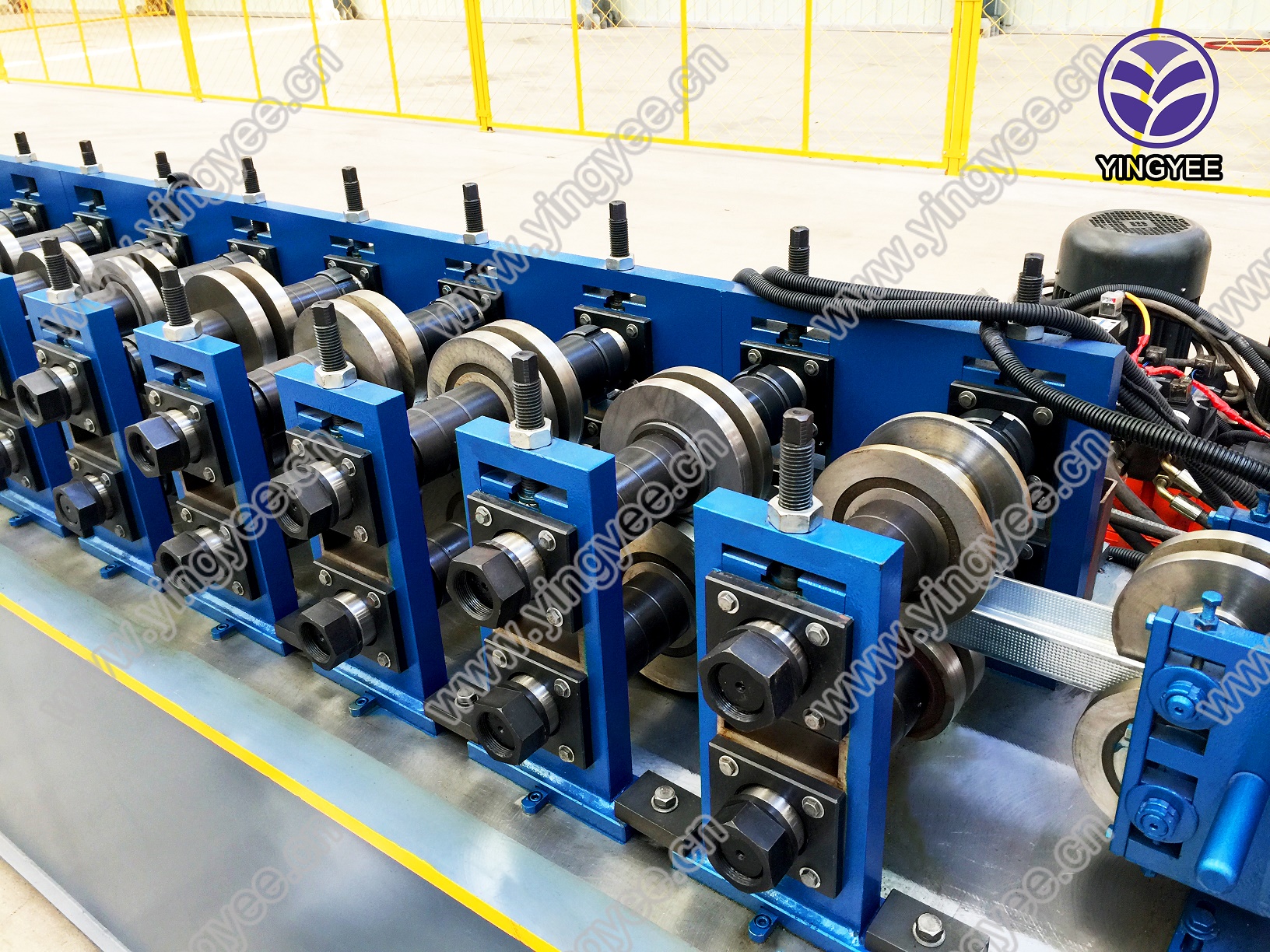

Regardless of the method used, coil cutting to length requires precision equipment and skilled operators to ensure accurate results. Modern cutting machines are equipped with advanced technologies such as computerized controls and automated feed systems to improve efficiency and accuracy. Operators must be trained to set up and monitor the cutting process to prevent errors and ensure consistency in the finished products.

In addition to precision cutting, quality control is also a crucial aspect of coil cutting to length. Finished sheets or strips must be inspected for defects such as cracks, burrs, or uneven edges. Any imperfections can affect the performance and durability of the final products, so it is essential to identify and correct them during the cutting process.

Overall, coil cutting to length plays a critical role in the manufacturing industry by providing high-quality metal sheets and strips for various applications. Whether it's producing components for automotive assembly or construction materials for buildings, coil cutting to length ensures that manufacturers can meet the demands of their customers with precision and efficiency. By investing in modern cutting equipment and skilled operators, manufacturers can enhance their production capabilities and maintain a competitive edge in the market.