The curved door frame roll forming machine represents a significant leap forward in manufacturing technology, particularly in the construction and architectural industries. With an unparalleled blend of precision engineering and cutting-edge automation, these machines have revolutionized how architects and builders approach design, allowing for more innovative and aesthetically pleasing structures without compromising on structural integrity.

Experience across numerous projects has shown that curved door frame roll forming machines not only enhance aesthetics but also bring tangible benefits in terms of structural performance. Traditional methods of creating curved structures typically involved labor-intensive processes and high material wastage. In contrast,

roll forming machines streamline the production line, minimizing manual intervention and significantly reducing waste. This means construction projects can be completed more efficiently and economically, while also adhering to environmentally sustainable practices.

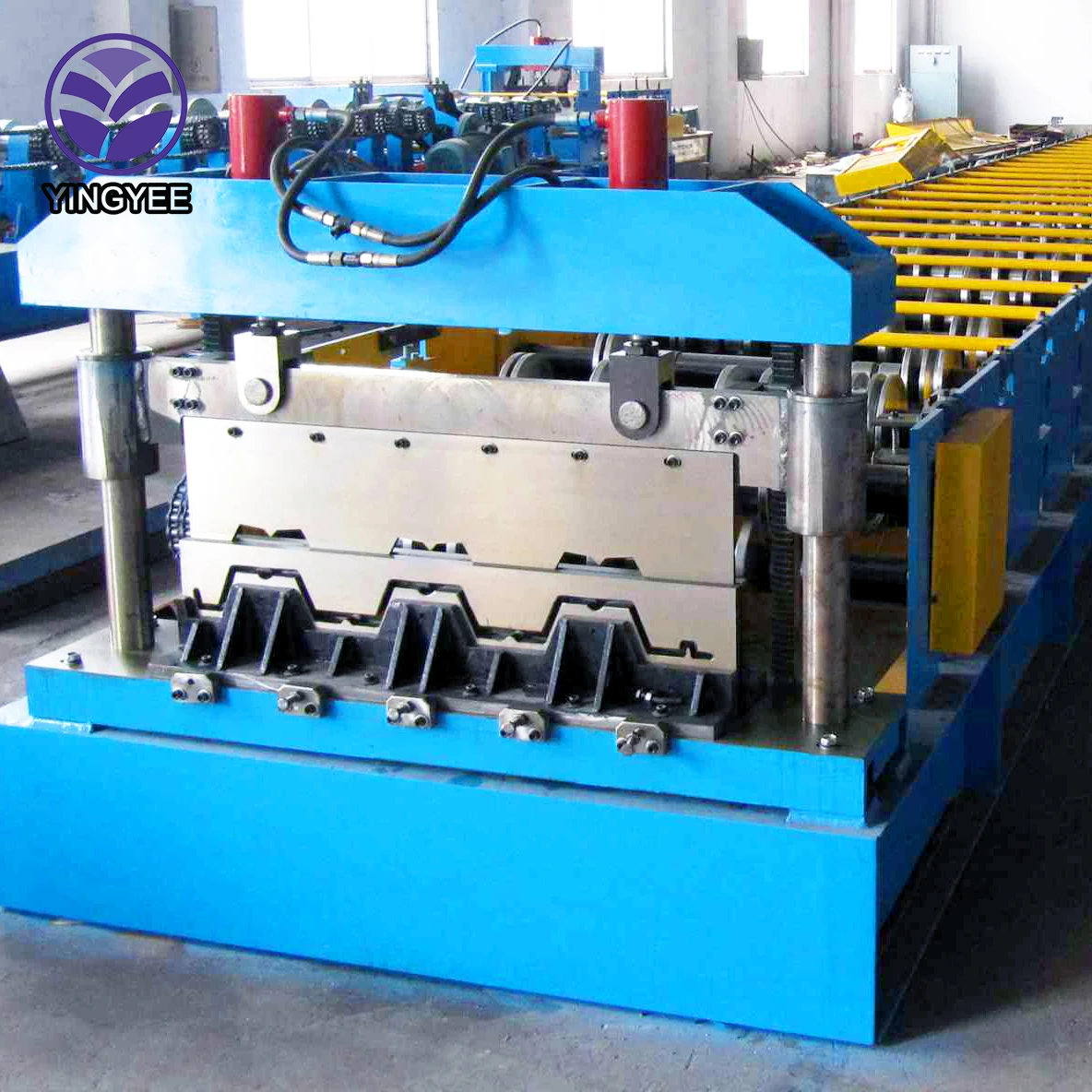

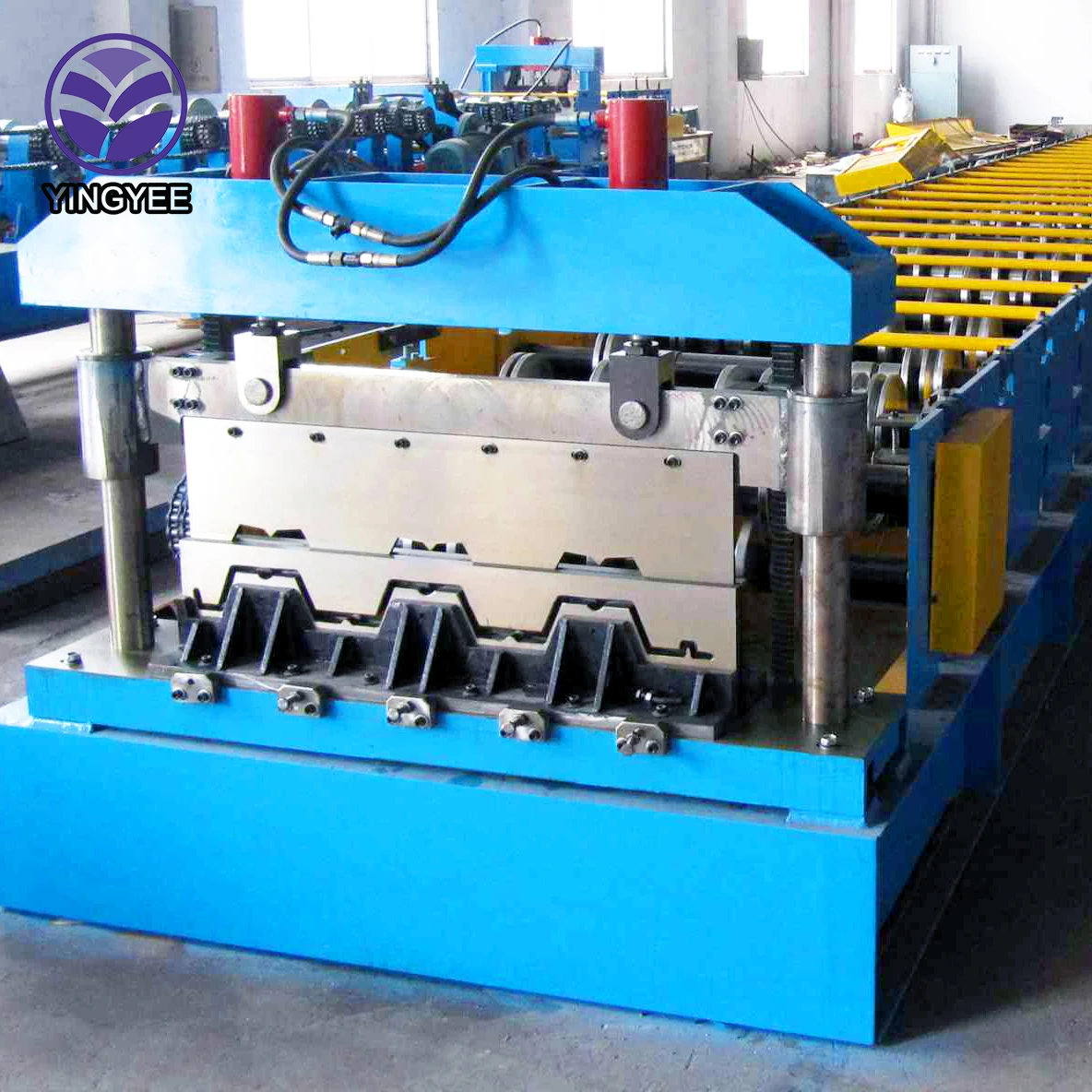

From an expert perspective, the curved door frame roll forming machine is a testament to engineering innovation. It operates by feeding metal coils through a series of carefully calibrated rollers, which gradually shape the metal into precise curvatures required for bespoke architectural designs. Each machine is equipped with advanced software controls that allow operators to adjust parameters such as curvature radius, material thickness, and length, ensuring a perfect fit for any project requirement. The customization capabilities mean architects can offer more personalized solutions to their clients, expanding their creative palette without extensive manual craftsmanship.

The authoritativeness of curved door frame roll forming machines in the construction sector is further solidified by their widespread adoption in major projects worldwide. Notable architectural feats—ranging from sports stadiums to avant-garde commercial buildings—have utilized these machines to achieve distinctive, smoothly contoured designs that capture attention and imagination. Industry leaders consistently vouch for the reliability and efficiency of these machines, acknowledging their crucial role in reducing lead times and labor costs.

curved door frame roll forming machine

In terms of trustworthiness, manufacturers of curved door frame roll forming machines prioritize quality and compliance with international safety standards. Each machine undergoes rigorous testing phases, ensuring it can consistently deliver high-quality products without operational failure. Moreover, continued advancements in machine technology, such as the integration of IoT and AI, enhance predictive maintenance capabilities, significantly reducing the risk of unexpected downtimes.

For those considering investing in this technology, the long-term cost benefits are substantial. Initial outlays are quickly offset by the efficiencies gained through automation, material savings, and reduced labor costs. Additionally, operators often provide extensive training and support, ensuring that end-users are fully equipped to maximize the potential of their machinery over its operational lifetime.

In conclusion, curved door frame roll forming machines are not just tools but pivotal components in modern construction, enabling architects and builders to push the boundaries of design while maintaining practicality and safety. The blend of experience, expertise, authoritativeness, and trustworthiness embedded in these machines ensures they remain at the forefront of architectural innovation, setting the standard for future developments in the field. The seamless integration of art and engineering that these machines facilitate is a testament to their value in transforming the aesthetic and structural landscape of the built environment.