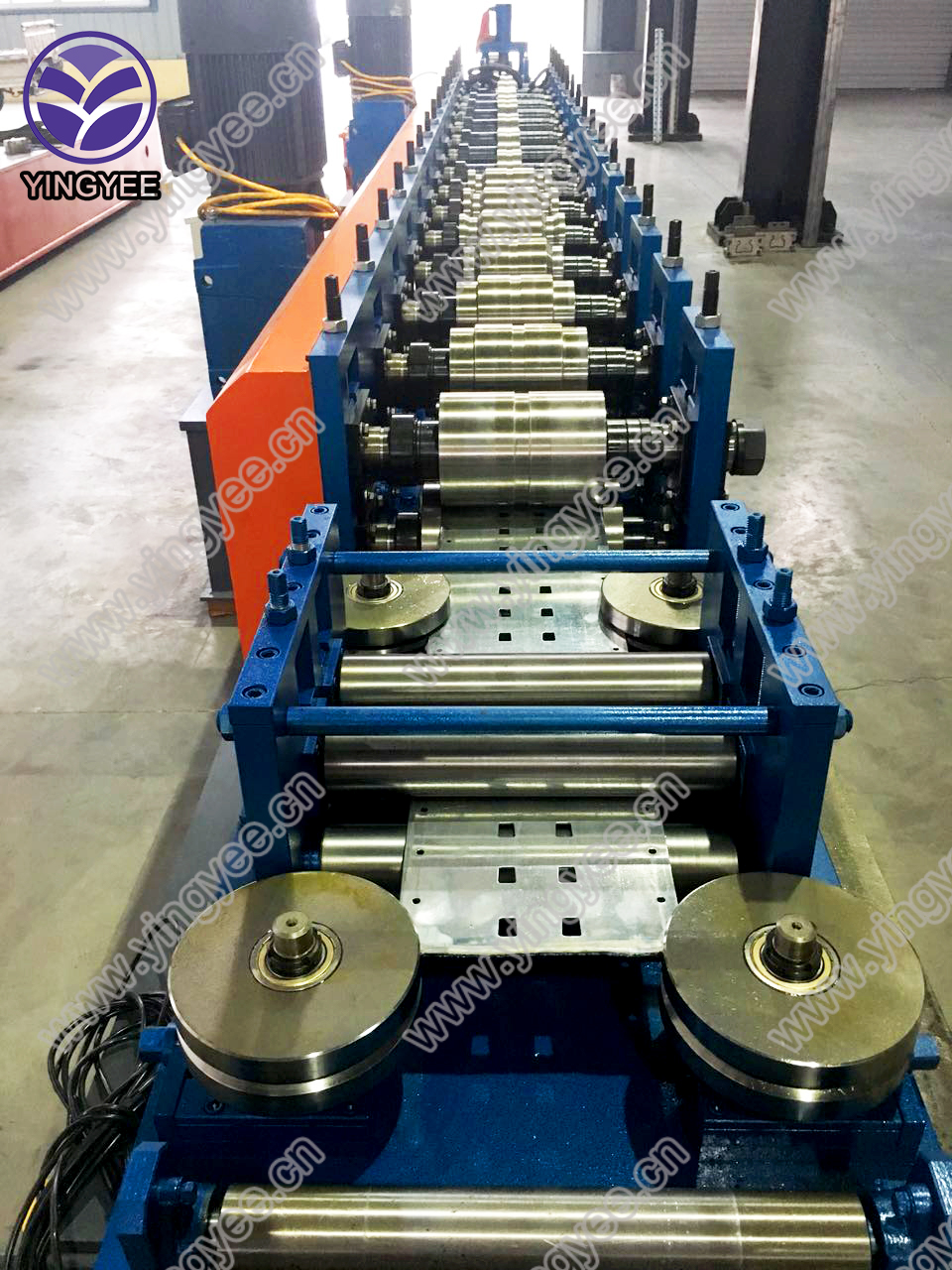

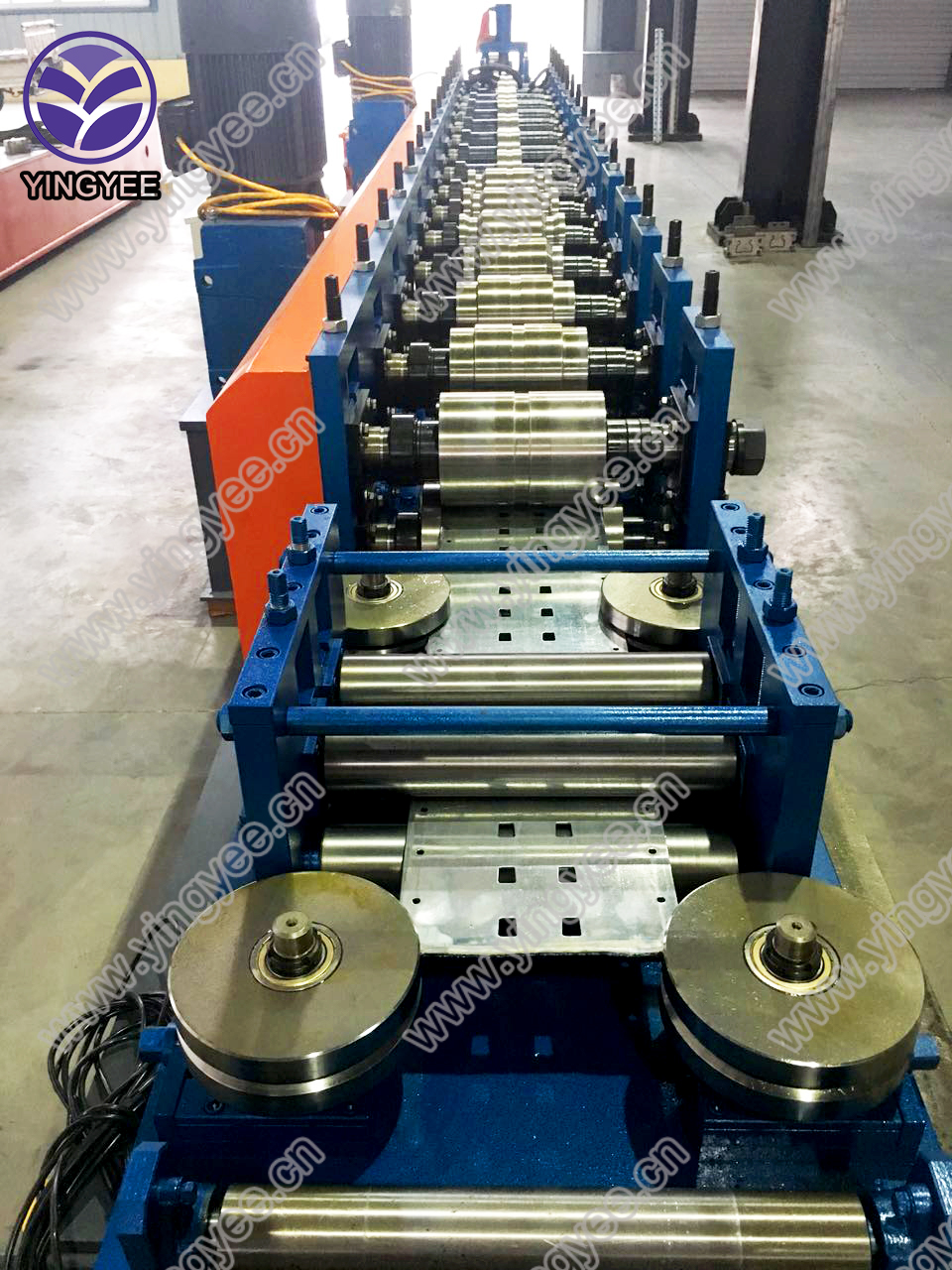

The corrugated sheet roll forming machine is a pivotal piece of equipment in the construction and industrial domains. Its innovation lies in transforming plain metal sheets into corrugated ones, a staple in roofing and cladding. This process ensures durability, longevity, and aesthetic enhancement.

From my extensive experience in this field, one cannot overlook the sheer efficiency and precision offered by modern corrugated sheet roll forming machines. Advanced models now come equipped with computerized control systems, ensuring that each sheet is uniform and meets stringent industry standards. This consistency is crucial for large-scale construction projects where discrepancies can lead to structural weaknesses.

Expertise in operating these machines is indispensable. A well-versed operator understands the myriad intricacies of feeding material, adjusting roll space, and managing the cutting mechanisms. This expertise minimizes wastage and maximizes productivity, translating into cost savings for businesses and clients.

Authoritativeness in this context isn't solely about the machine's ability to produce quality sheets. It's also about the manufacturer's reputation and history in the industry. Brands that have invested in research and development, ensuring their machines are at the technological forefront, tend to lead the market. These manufacturers often offer extensive training programs and after-sales support, reinforcing their commitment to quality and customer satisfaction.

corrugated sheet roll forming machine

Trustworthiness is paramount when choosing a corrugated sheet roll forming machine. The machine's reliability impacts project timelines and overall construction quality. Users should look for machines built with robust materials designed to withstand intensive use. Customer testimonials and case studies often shed light on a machine's performance under various conditions, offering insights that can't be learned from spec sheets alone.

Furthermore,

regular maintenance is essential to ensure the longevity of a roll forming machine. Routine checks on the rollers, cutting systems, and computerized controls prevent unexpected downtimes and costly repairs. Investing in a machine from a reputable manufacturer often means gaining access to a network of service professionals who are adept at diagnosing and resolving issues promptly.

In conclusion, the corrugated sheet roll forming machine is not just a tool but a cornerstone of modern construction and industrial practices. Its ability to deliver uniform, high-quality corrugated sheets efficiently cannot be understated. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can ensure they select the right machine for their needs, one that will provide both cost-efficiency and top-tier performance.