Cold Purling Roll Forming Machine An Overview

In the realm of modern construction, the importance of efficient and effective building materials cannot be overstated. One such innovation in this field is the cold purling roll forming machine, which is designed to fabricate high-quality purlins used in various structural applications. This machine employs a continuous roll forming process that shapes metal strips into purlins, which are critical components in framing systems for commercial buildings, warehouses, and more.

What is a Cold Purling Roll Forming Machine?

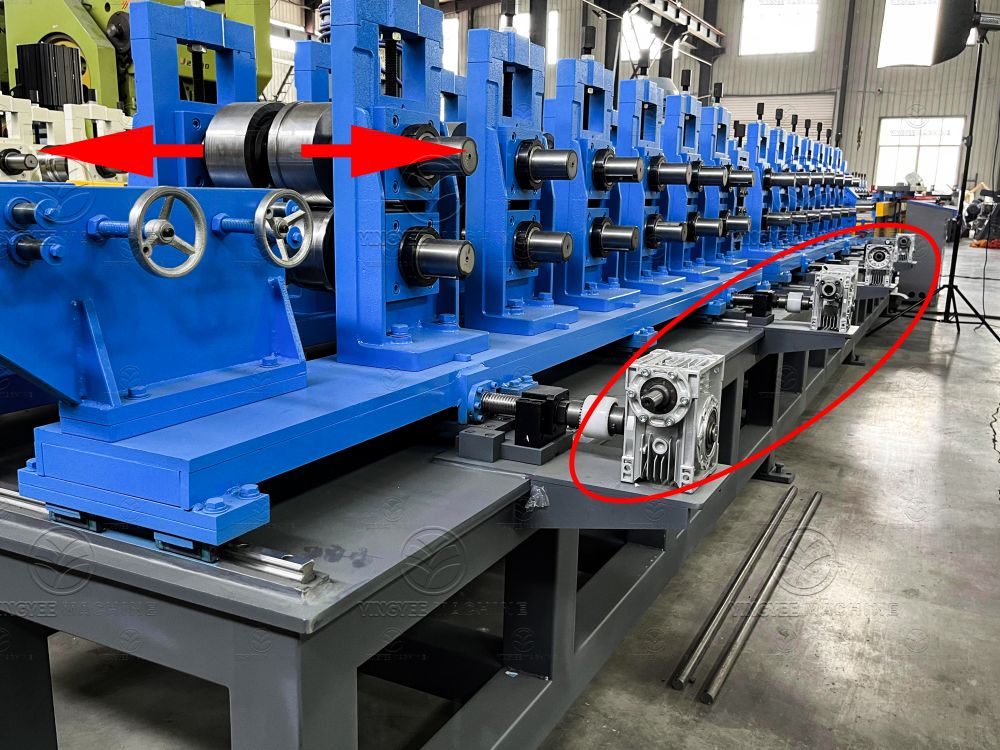

A cold purling roll forming machine is a specialized piece of equipment that utilizes a series of rollers to transform flat metal sheets into specific shapes without the application of heat. The process begins with feeding the raw metal, often steel or aluminum, through a series of rollers that progressively shape it into the desired profile. This method is known for its efficiency, precision, and the ability to produce complex shapes consistently.

Benefits of Using Cold Purling Roll Forming Machines

The use of cold purling roll forming machines offers several advantages over traditional manufacturing methods

1. Material Efficiency The roll forming process minimizes waste by utilizing nearly the entire width of the metal sheet. This contrasts with other fabrication methods, where excess material is often discarded.

2. High Strength-to-Weight Ratio The resulting purlins are not only lightweight but also extremely strong, making them ideal for structural applications. The cold forming process enhances the mechanical properties of the steel, contributing to greater durability and load-bearing capacity.

3. Customization These machines can be designed to produce purlins in various sizes and profiles, catering to the specific needs of different construction projects. This flexibility allows manufacturers to meet market demands effectively.

4. Automation and Speed Many modern cold purling roll forming machines are equipped with advanced automation features. This capability results in quicker production times and reduced labor costs, subsequently increasing overall efficiency.

5. Reduced Maintenance Machines designed for cold roll forming typically require less maintenance compared to other manufacturing machines, thanks to their robust construction and fewer moving parts.

Applications of Cold Purling

Cold purlins are primarily used in steel structures, particularly in the construction of roofs and walls. They serve as support beams, helping to distribute loads evenly across the building structure. Their versatility allows them to be employed in various sectors, including industrial, commercial, and agricultural construction.

Conclusion

In summary, the cold purling roll forming machine represents a significant advancement in the manufacturing of structural components. With its numerous benefits, including efficiency, material savings, and the ability to produce customized profiles, this machine has become a crucial asset in the construction industry. As building demands continue to evolve, the role of cold purling roll forming machines will likely expand, solidifying their place in modern construction practices. As manufacturers adopt more sophisticated technologies, the future of this equipment looks increasingly promising, paving the way for more innovative construction solutions.